Hi everyone,

Just a quick question,

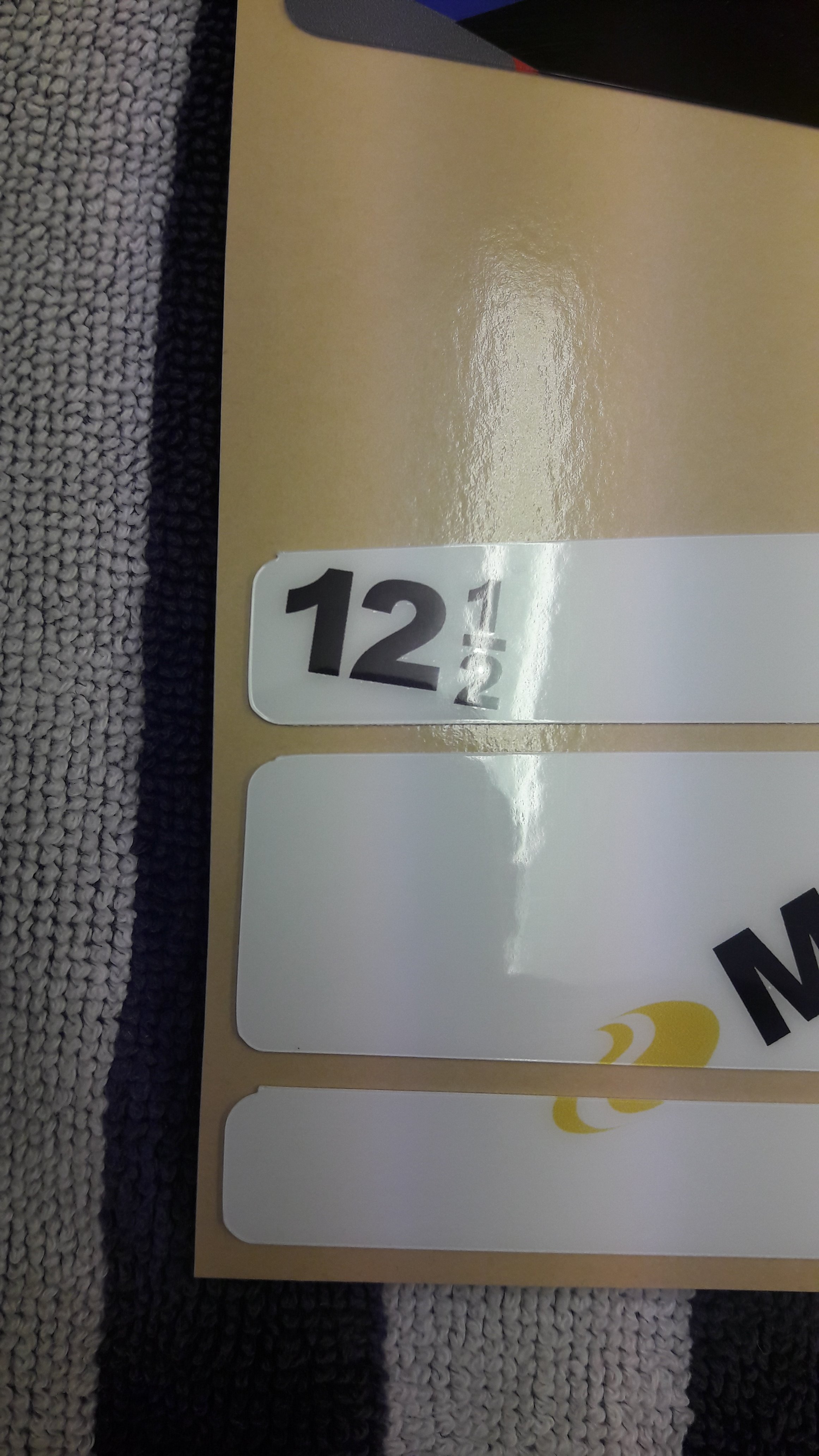

I use my Graphtec FC8000 for cutting around my Motocross templates but when the machine comes to finish its cut the shapes haven't joined the best from when the blade started and finished the cut but only very little.

How would I improve this? Simple setting?

I have attached an image

Thanks

Just a quick question,

I use my Graphtec FC8000 for cutting around my Motocross templates but when the machine comes to finish its cut the shapes haven't joined the best from when the blade started and finished the cut but only very little.

How would I improve this? Simple setting?

I have attached an image

Thanks