-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Large sign - material choice help!

Unless you can find a 50' peice of alumalite..... -

-

So what is your hobby

Moshing, drinking, picking up hitch-hikers.- Mosh

- Post #73

- Forum: General Chit-Chat

-

Trailer Wrap gone Bad!!!

You added three screws???????? Why? Doing that makes you liable for sure! We wrap trailers for a trailer manufacturer, they have NO problem with us removing screws, as long as we put them back...and don't add any!!!- Mosh

- Post #17

- Forum: Vehicle Wraps

-

aluminum welding

I have a Miller Bobcat 250 with a spool gun for the aluminum (so I don't have to change reals) Yes, a TIG will give better looking results, a MIG is faster and cheaper to do. A little practice and it is easy. Aluminum does take some prctice. But you can't do light sheets like 040 very easily...- Mosh

- Post #8

- Forum: General Signmaking Topics

-

Thinking of buying the SignWarehouse Vehicle Wrap Kit

He manned up. I lost two of my biggest accounts this year to "in-house" printing. The stuff they have been putting out is a joke and I hope to soon get them back because of this!- Mosh

- Post #66

- Forum: Vehicle Wraps

-

Dating idea

Crap, I thought this was going be be on how to pick up women! (dating idea) -

Too cheap for a take-up reel

You guys are all SO LOW BUDJET!!!!! Like the dude that can't afford a plotter that uses an exato knife. It still works but.....- Mosh

- Post #22

- Forum: Digital Printing

-

Vinyl/App Tape Roll Plastic Plugs

We get them in all of our film rolls, you want me to start saving them up for you?- Mosh

- Post #9

- Forum: General Signmaking Topics

-

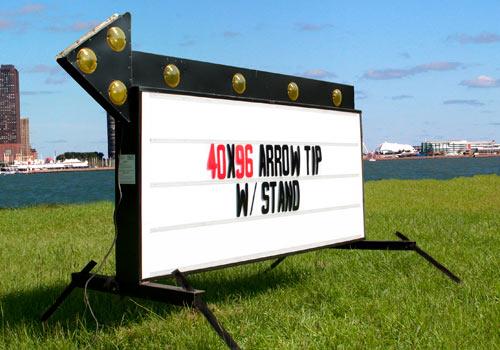

Anyone know a good wholesaler for Flashing Arrow Sigh with Changeable Letters?

Most places around here they are illegal too. I saw one at the Sam's in Omaha last month.- Mosh

- Post #7

- Forum: Electric Signs & Channel Letters

-

Anyone know a good wholesaler for Flashing Arrow Sigh with Changeable Letters?

Sam's has these for under $450.00- Mosh

- Post #4

- Forum: Electric Signs & Channel Letters

-

Brick Facade, what to use

Use Max-Metal or diabond. Install an exstruded aluminum frame, and simply slide the face in. The frame can be attacked with concrete anchors in the motor of the brick. -

Thinking of buying the SignWarehouse Vehicle Wrap Kit

+1 for not thinking you are in the sign biz and looking for cheap do-it-yourself Paul Jr. type of person. Sorry, but this is the type of crap that I hate. Leave the printing to the printers.- Mosh

- Post #19

- Forum: Vehicle Wraps

-

Intermediate VS. High Performance 3M vinyl

220, I have stuff that has been up 20+ years. -

The List of Questions

How much they want to spend is the first thing I ask. It cuts out all the tire-kickers.- Mosh

- Post #8

- Forum: Sales, Marketing, Pricing Etc.

-

need something to say to liar solicitors

Tell them you don't have a cell phone....- Mosh

- Post #24

- Forum: General Chit-Chat

-

Pay Your Bills.

omg, did it work. I have "re-poed" signs before, only about 1/2 come and pay.- Mosh

- Post #4

- Forum: General Signmaking Topics

-

I think I was visited by a crook!!!!

You better stay there tonight late. If I was closer I would come hang around your shop all night, that would be one suprise when they brake in and there is the Mosh waiting for them, armed and loaded (my gun loaded too)- Mosh

- Post #7

- Forum: General Chit-Chat

-

Yes, you can get arrested....

Glad no one was seriously hurt or killed!- Mosh

- Post #6

- Forum: General Signmaking Topics

-

-

real estate riders!!

I get $10 for coro riders (one offs)- Mosh

- Post #17

- Forum: General Signmaking Topics