-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

-

-

SP 300 V print problems

Ohhhhh, geez. Have you looked in the top side of the carriage to see if any issues might have happened inside? From your photo I thought it was just a bad jpeg.. didnt realize that was ink. -

SP 300 V print problems

similar issue I find my XJ-640 dropping randomly throughout prints. This instance it was black ink, others its Magenta. It was recently serviced by a Roland certified tech and fresh dampers installed as well. Not sure if this is a static issue or not. It's not our everyday printer so I'm not... -

Versacamm Help Required. Cleaned Head Now Not Printing

Check the pump hoses that connect to the pump below the damper. These may be clogged and not pulling anything through. -

Surf Shop Vehicle wrap concept

Make sure you tell them with a roof wrap it needs to be removed before 4 years or it will cost at least 2 times the regular removal.- 63Comet

- Post #6

- Forum: Vehicle Wraps

-

Help! Removing decals from wrap?

Pass, any panel you try to remove from will be ghosted, the panel in the photo will not be repairable and will need to be replaced... If I where you and it is only the truck bed, give them a price on a rewrap for just those panels, should be able to split a roll and get both sides redone.- 63Comet

- Post #15

- Forum: Vehicle Wraps

-

Ink ran out, now cyan not printing at all...

soak the cap and see if its hose is clogged.. just had to unclog one in our roland. The hose sits low and pools inside... design flaw if you ask me. Soak the pad pull the hose and squeeze form the top to the bottom when you stop seeing bubbles that's where the clog needs worked out. after you... -

Maintaining a colored background for a contour cut

Pleasuring yourself via forum.... hmmmm sounds a little too risque for a printers forum.... "Bob" -

Printhead Cleaning Solution or alcohol and something else?

Ok, it was unclear to me but I figured before I have a purchase request in I'd ask. -

Printhead Cleaning Solution or alcohol and something else?

I did notice that some people mix their own has anyone done this? I can make a purchase request for actual printhead cleaner but I was wondering if we could make our own. -

HELP! Latex mesh banner issue

Digging up an old thread, but I had this problem this week, made this correction, Which worked great! But I wanted to add that the lead edge needed fed out of the machine to keep the front from catching, that or run tape on the leading edge to keep it from separating.- 63Comet

- Post #6

- Forum: General Signmaking Topics

-

L26500 window cling

Thanks guys, we had concerns that the heat would cause head strikes. Good to hear it should be painless!- 63Comet

- Post #4

- Forum: Hewlett Packard

-

L26500 window cling

Has anyone ran cling... I'm guessing its probably a tough thing to handle so I figured I'd around. If so what heat did you run?- 63Comet

- Thread

- Replies: 5

- Forum: Hewlett Packard

-

Constant "Substrate Jams" on L260

What substrate are you printing on, are you over heating? Have you installed the edge protectors? What is your vacuum setting at... all these things can contribute to jams.- 63Comet

- Post #8

- Forum: Hewlett Packard

-

L26500 Vinyl Banner leading print edge issue

.........then perhaps it should be a sticky.- 63Comet

- Post #11

- Forum: Hewlett Packard

-

L26500 Vinyl Banner leading print edge issue

What are you running at, I have tried to keep the temp lower to keep the the distortion down. I'm running 8 bidi, 50c dry, 100c cure, 45% airflow- 63Comet

- Post #8

- Forum: Hewlett Packard

-

HP L26500 Cutter not working

Check your rip software it may be disabled.- 63Comet

- Post #7

- Forum: Hewlett Packard

-

-

L26500 Vinyl Banner leading print edge issue

Did it happen to stop part way through your print? I would agree with you but I would think if it where only caused by this that it would be consistent throughout the print.- 63Comet

- Post #3

- Forum: Hewlett Packard

-

L26500 Vinyl Banner leading print edge issue

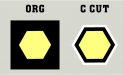

I am running forward banner, on the first 4-6 inches of the print I do not get a proper cure and get the weave pattern from the roller in the image. I built in an 8 inch advance so that it would pull fresh and not print on what had been sitting in the machine during warm up. Is there something...- 63Comet

- Thread

- Replies: 13

- Forum: Hewlett Packard