MJDallas

New Member

Hi there,

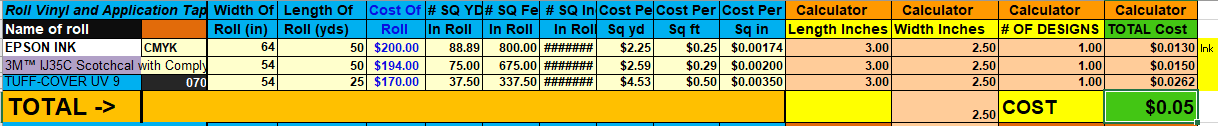

I am trying to see if my material cost seems right... It appears REALLY low- but it may be correct on a small decal.

Size: 3" by 2.5".

Equipment: Epson S60600.

I use a formula that calculates the ink per sq/ft to be about 25 cents. Using IJ35 vinyl and GMS' Tuff-Cover UV9 laminate, I come up with a total cost of FIVE CENTS per decal...

I feel like I am missing something big here. Can someone take a look and let me know what you think?

I am trying to see if my material cost seems right... It appears REALLY low- but it may be correct on a small decal.

Size: 3" by 2.5".

Equipment: Epson S60600.

I use a formula that calculates the ink per sq/ft to be about 25 cents. Using IJ35 vinyl and GMS' Tuff-Cover UV9 laminate, I come up with a total cost of FIVE CENTS per decal...

I feel like I am missing something big here. Can someone take a look and let me know what you think?