tranceraider

New Member

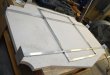

So the customer wanted a hanging HDU sign, it is about 62"w x 35"h. They wanted it double sided so we purchased two 1" HDU panels and were going to glue them together. Instead of just purchasing a 2" thick and have it routed on both sides we chose two single sided panels so we could glue them together and route out a spot for some all thread so we can hang the sign and not have the hooks just snap off in a storm.

I guess the question is, what would be the best practice to attach two 5'x3' panels of HDU, and do you think there is a better way to make it a hanging sign then what we are thinking of doing. They also want to hang riders underneath the sign, which made the all thread make even more sense. And just attach hooks/ihooks to the ends of the all thread.

Just wondering what glue is best to hold two signs together, and if there is any need to add more support like dowels or something to hold both signs together.

Thanks for all your suggestions.

I guess the question is, what would be the best practice to attach two 5'x3' panels of HDU, and do you think there is a better way to make it a hanging sign then what we are thinking of doing. They also want to hang riders underneath the sign, which made the all thread make even more sense. And just attach hooks/ihooks to the ends of the all thread.

Just wondering what glue is best to hold two signs together, and if there is any need to add more support like dowels or something to hold both signs together.

Thanks for all your suggestions.