MJDallas

New Member

Hi, I know these are two completely different machines....

We are in the market for a printer, instead of outsourcing since our business has been growing lately. We initially started as a safety decal company, but have wanted to expand to doing a lot more for our customers since the requests have been coming in.

Since we were initially looking at safety decals, we wanted to go with a Summa DC5, as it prints/cuts, but we still. have to laminate it or find thicker media to print on. Customers don't like what samples we have been providing (the ControlTac media has been too thin- can't remember which one, but I know it is 2mm).

Grimco told me about an Epson 60600 they have on special that looks good, but I am concerned about the print quality based on the sample I just received at 16 passes.

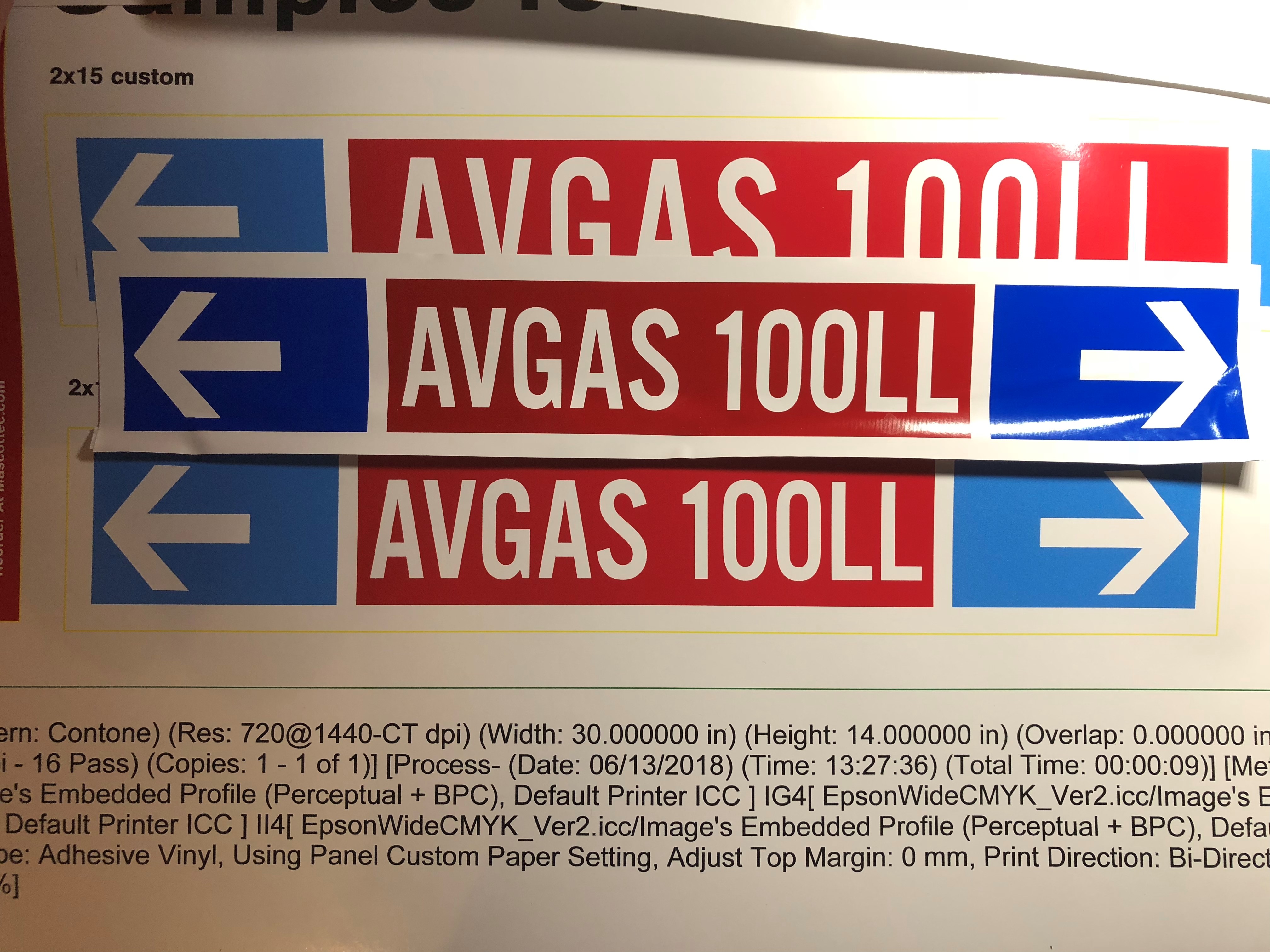

Below, I laid the Summa decal (darker blue) on top of the Epson print sample. I did not send the correct color to Grimco when printing the sample and only used the Summa color pallet- so I get there was going to be a color difference. The Summa looks for a certain color to tell it what ribbon to use. What concerns me is the solid blocks of blue from the Epson do not look good (where the arrows are).

My question is... Is this normal of the Epson printers to print such a dithered look? Is that even the right term?? Most of our work is solid colors, so that has to be spot on.

I also noticed that the sample they printed was at 16 passes. Can I get similar quality at less passes? This is not fine art, they are decals, but they cannot have banding either.

Suma Banding issue:

I LOVE the color of the Summa, but I don't like the high cost per print. Ignore the tear. I was seeing how tear resistant the media was.

Epson printing the correct blue in a different area. This blue is MUCH better. But again, at 16 passes, which worries me.

Recap questions:

1. Can I get similar quality (in terms of no banding and darkness of print) with less passes?

2. What is the cost difference (I hear .24 cents per sq ft of ink- but at how many passes?) between different pass settings?

3. Are there different factors that play into the ink costs anywhere in the machine? I can't imagine so... I figure it is all down to how many passes you lay.

4. Any ideas on the "dithering"?

5. For outdoor decals (primary business), would you go with the Epson 60600 and laminate or the Summa DC5 (and probably still laminate). Decals need to last 3 years.

Also, before anyone says anything, we do have someone full time that can maintain the machine. I understand it is a lot of work to maintain the solvent printers. Finally, we are outsourcing to a large company that could not care less about our business- not a local shop, so this is helping us move on our own.

Thanks!

FFNG (Fairly FNG) Mike

We are in the market for a printer, instead of outsourcing since our business has been growing lately. We initially started as a safety decal company, but have wanted to expand to doing a lot more for our customers since the requests have been coming in.

Since we were initially looking at safety decals, we wanted to go with a Summa DC5, as it prints/cuts, but we still. have to laminate it or find thicker media to print on. Customers don't like what samples we have been providing (the ControlTac media has been too thin- can't remember which one, but I know it is 2mm).

Grimco told me about an Epson 60600 they have on special that looks good, but I am concerned about the print quality based on the sample I just received at 16 passes.

Below, I laid the Summa decal (darker blue) on top of the Epson print sample. I did not send the correct color to Grimco when printing the sample and only used the Summa color pallet- so I get there was going to be a color difference. The Summa looks for a certain color to tell it what ribbon to use. What concerns me is the solid blocks of blue from the Epson do not look good (where the arrows are).

My question is... Is this normal of the Epson printers to print such a dithered look? Is that even the right term?? Most of our work is solid colors, so that has to be spot on.

I also noticed that the sample they printed was at 16 passes. Can I get similar quality at less passes? This is not fine art, they are decals, but they cannot have banding either.

Suma Banding issue:

I LOVE the color of the Summa, but I don't like the high cost per print. Ignore the tear. I was seeing how tear resistant the media was.

Epson printing the correct blue in a different area. This blue is MUCH better. But again, at 16 passes, which worries me.

Recap questions:

1. Can I get similar quality (in terms of no banding and darkness of print) with less passes?

2. What is the cost difference (I hear .24 cents per sq ft of ink- but at how many passes?) between different pass settings?

3. Are there different factors that play into the ink costs anywhere in the machine? I can't imagine so... I figure it is all down to how many passes you lay.

4. Any ideas on the "dithering"?

5. For outdoor decals (primary business), would you go with the Epson 60600 and laminate or the Summa DC5 (and probably still laminate). Decals need to last 3 years.

Also, before anyone says anything, we do have someone full time that can maintain the machine. I understand it is a lot of work to maintain the solvent printers. Finally, we are outsourcing to a large company that could not care less about our business- not a local shop, so this is helping us move on our own.

Thanks!

FFNG (Fairly FNG) Mike

Attachments

Last edited: