signbrad

New Member

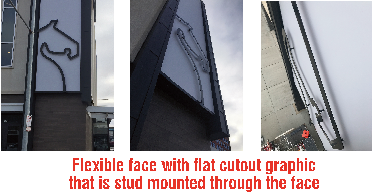

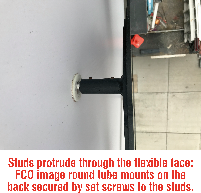

We plan to replicate the sign shown in the first three pictures. The flat cutout aluminum graphic is mounted in front of the flexible face, studs passing from the back of the cabinet through holes cut in the face. We are trying to figure out what the grommet-looking things are that the fabricator used on the holes where the studs pass through the face.

The second photo shows the detail of the stud passing through the face.

Anyone done this before?

Brad in Kansas City

The second photo shows the detail of the stud passing through the face.

Anyone done this before?

Brad in Kansas City