Gnome Beard

Guest

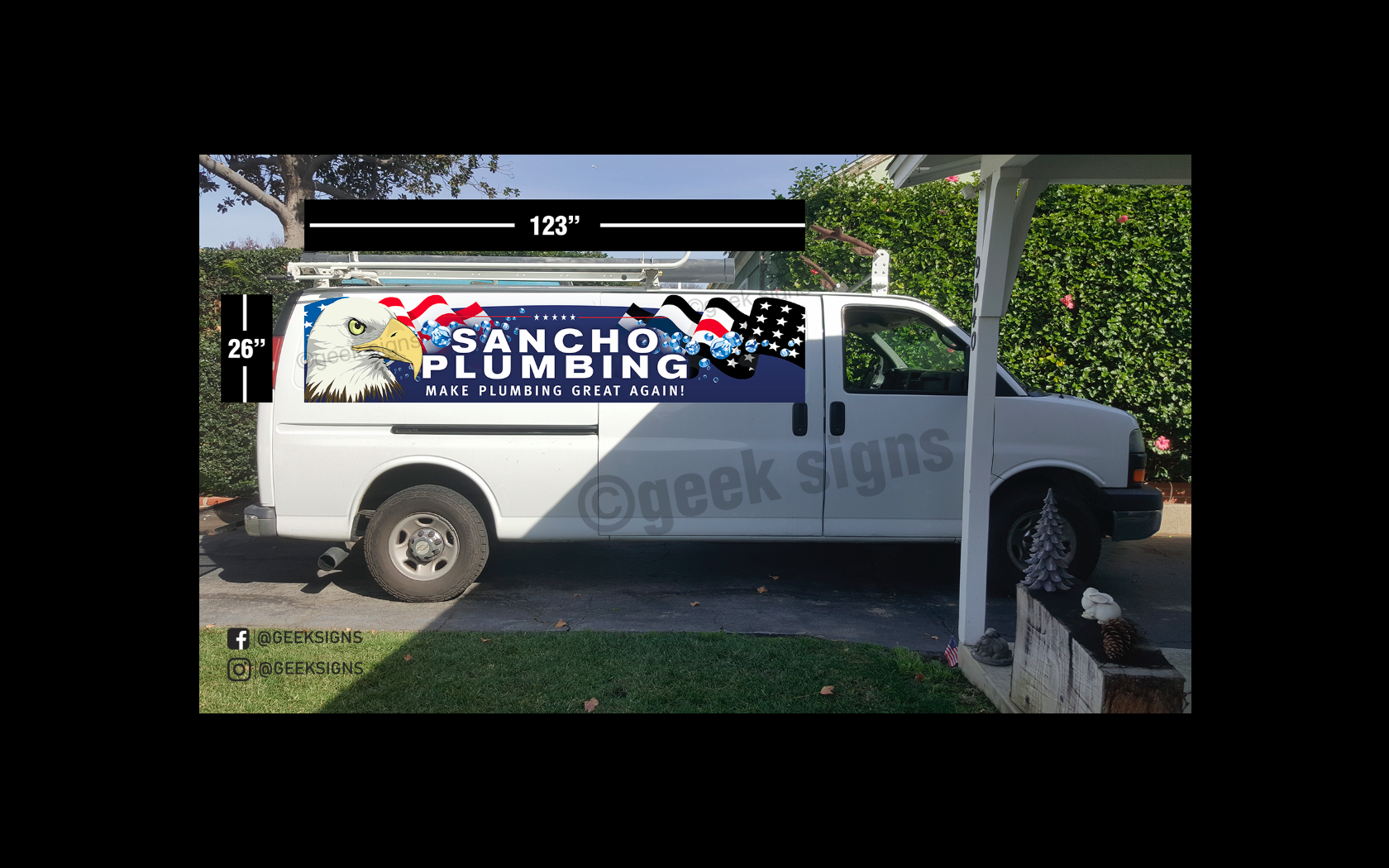

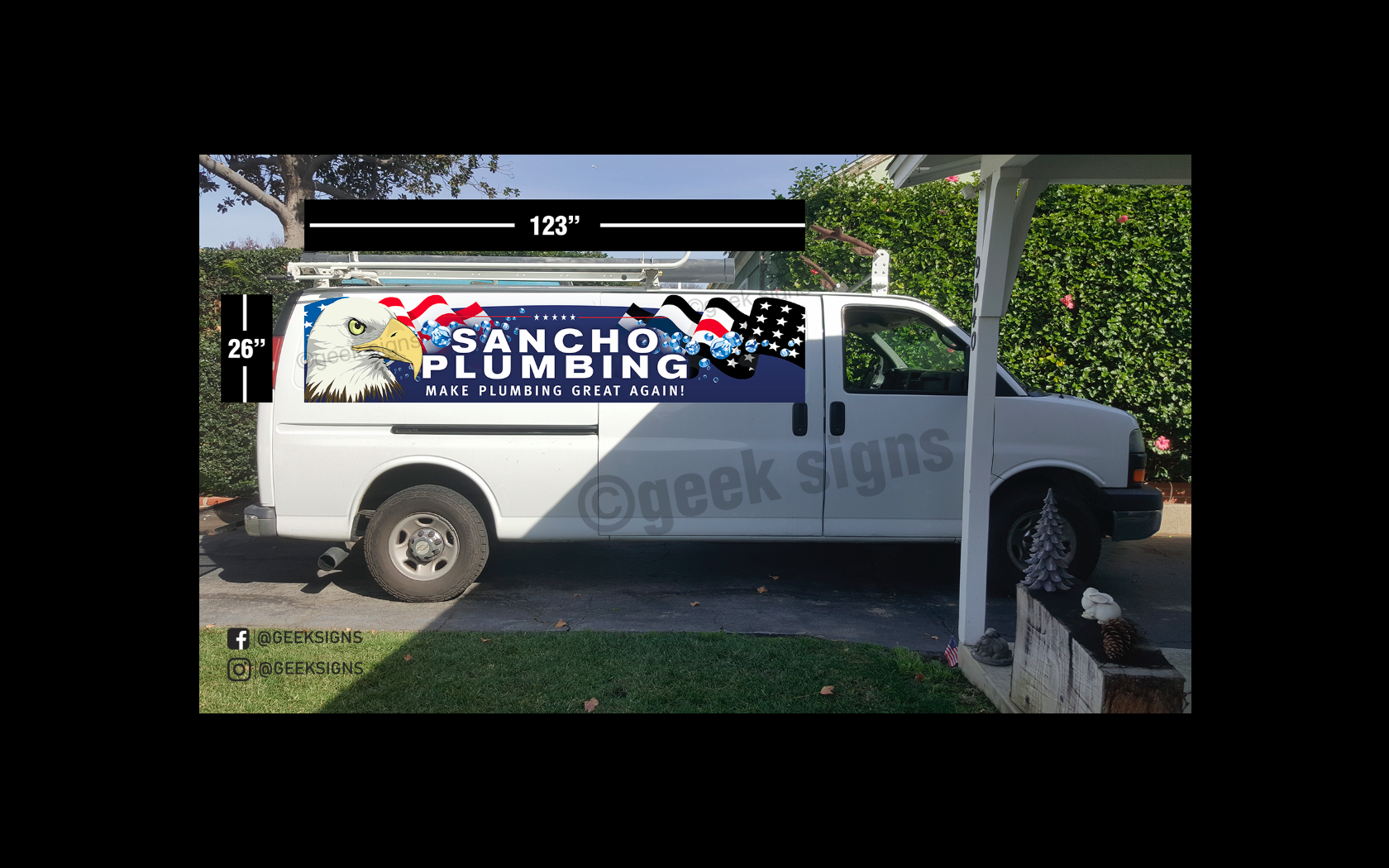

I am doing a partial wrap on the sides of a van and wanted to do a contour cut. It's not a complex CutContour, but it is about 123" long. Can my Graphtec FC8600 handle this job? I'm printing on a 54" roll, wish I can print side by side, but I cannot. Pictures attached.