Hi everyone

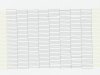

I have a Mimaki JV33 printer which has a clogged black printhead. When I do a test draw the black is misaligned and is over spraying. The other colors are fine though.

I'm running standard Eco ES3 OEM inks with the original printhead. I bought the printer new in 2012 and have only printed 1000m2 since then. I've had the printer serivced once since then with a new capping station and wiper blade.

I don't use my printer alot so I'm thinking what might have happened is that the black ink has dried up with little use?

I've tried multiple hard cleans and 2 overnight/socking nozzle washs but with no success. I get the same test draw everytime.

I know my printer looks a little dirty but even after I clean it, it still has the same problem.

I print mostly billboards so I can get away with having it like this (its been like this for 4 months), but when I do a job that requires small text the black looks horrible.

I've read about something to do with manual flashing with clean solution with a syringe through the printhead, but I coudn't find any instructions relating to the JV33.

Any help is appreciated

I have a Mimaki JV33 printer which has a clogged black printhead. When I do a test draw the black is misaligned and is over spraying. The other colors are fine though.

I'm running standard Eco ES3 OEM inks with the original printhead. I bought the printer new in 2012 and have only printed 1000m2 since then. I've had the printer serivced once since then with a new capping station and wiper blade.

I don't use my printer alot so I'm thinking what might have happened is that the black ink has dried up with little use?

I've tried multiple hard cleans and 2 overnight/socking nozzle washs but with no success. I get the same test draw everytime.

I know my printer looks a little dirty but even after I clean it, it still has the same problem.

I print mostly billboards so I can get away with having it like this (its been like this for 4 months), but when I do a job that requires small text the black looks horrible.

I've read about something to do with manual flashing with clean solution with a syringe through the printhead, but I coudn't find any instructions relating to the JV33.

Any help is appreciated