DrunknMonk

New Member

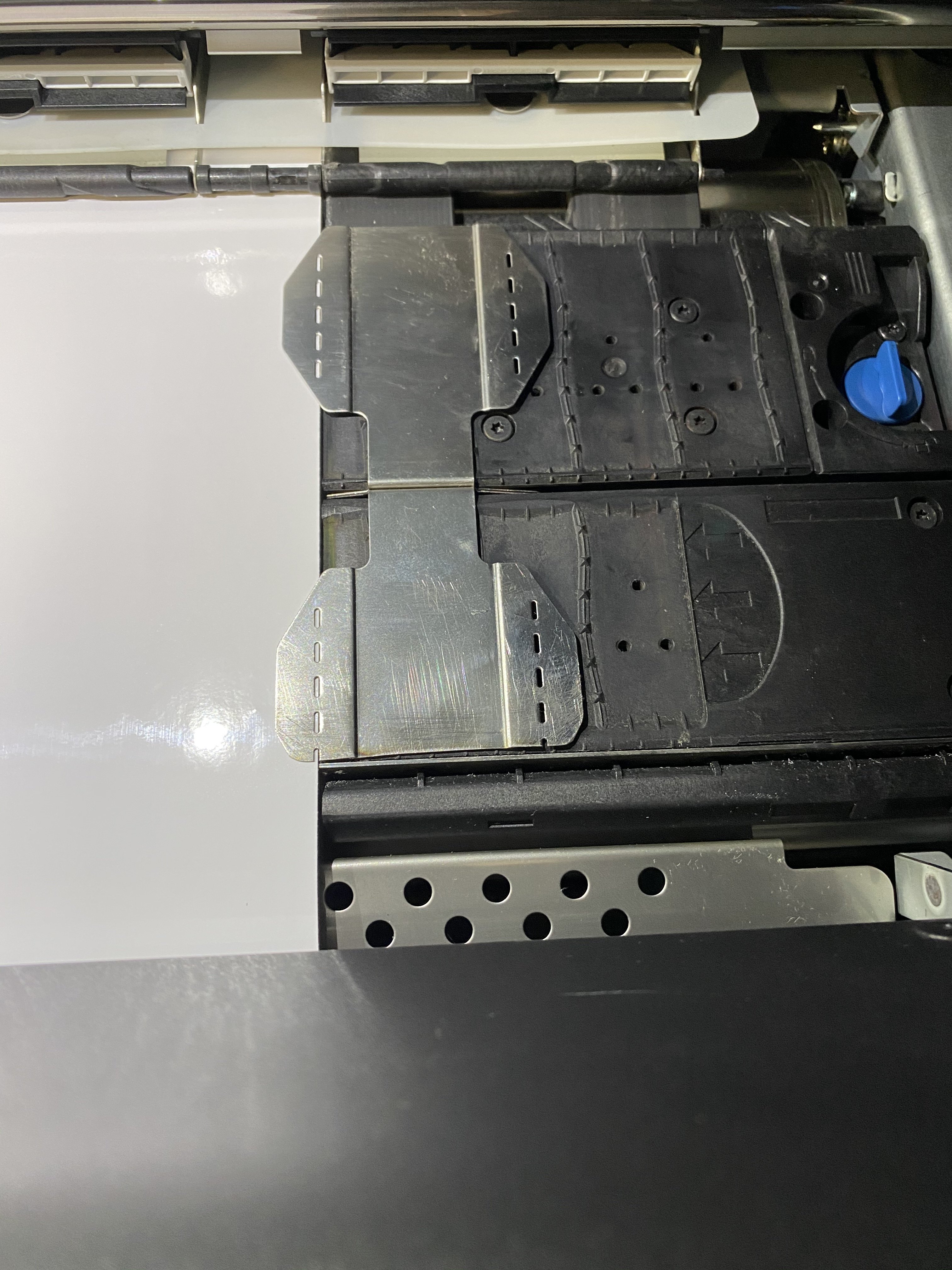

Hi all, Ive been using the printer for over 2 years with very little head strikes, Now im getting them all the time, I will post some picts and a video.

things ive done

Added additional edge/vinyl holders, cleaned the backs of them.

cleaned all the holes in the suction bed

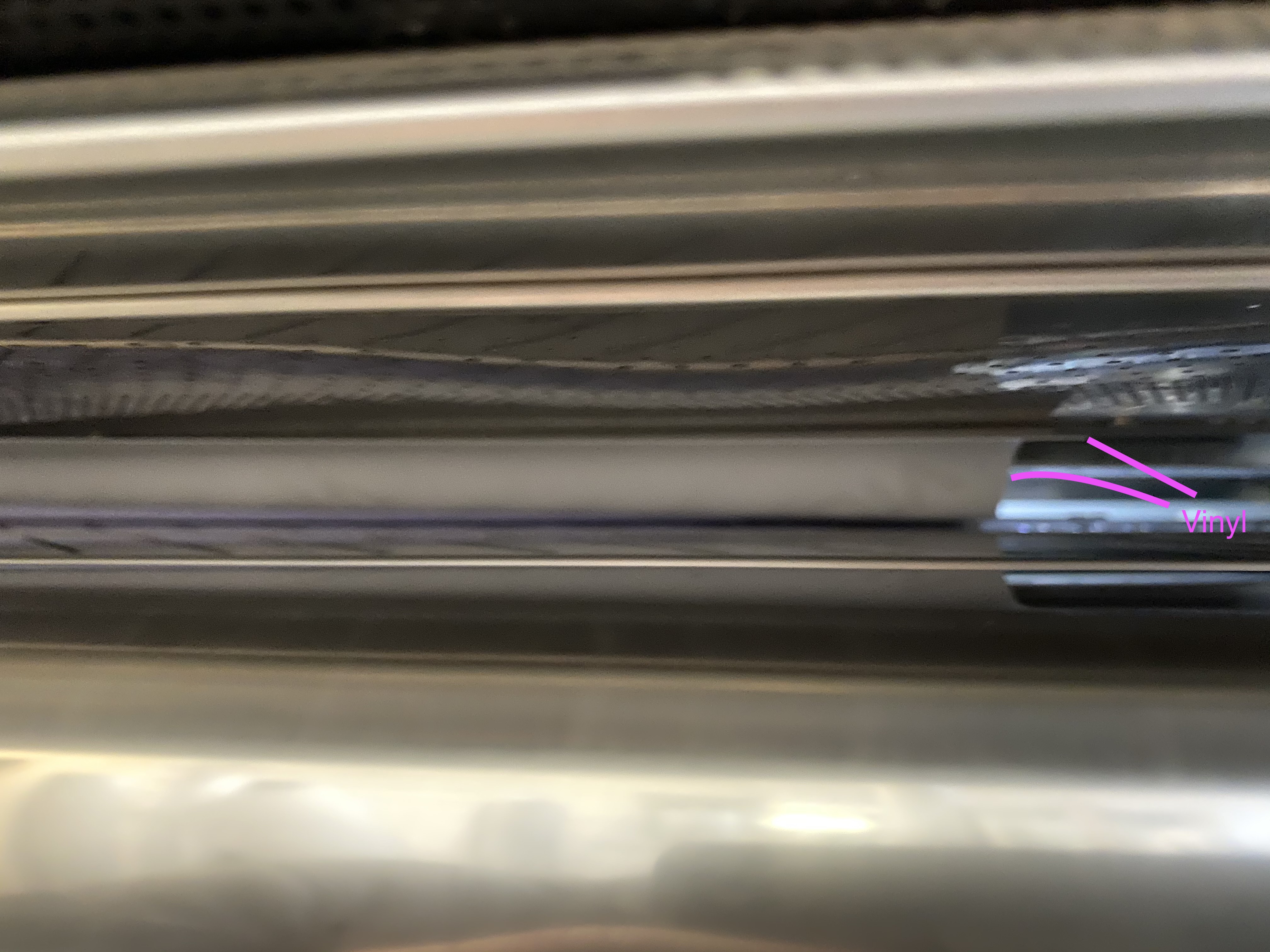

cleaned the curved stainless steel bed

added more suction to the printed jobs

it seams that its gathering under the heater, ive put my hand under it I can't feel any glue there, but its hard to reach.

Its ok if I use the take up, but ive been running 1m prints without the take up not problem for years.

Its the same material as I always run.

not sure what else to try !

things ive done

Added additional edge/vinyl holders, cleaned the backs of them.

cleaned all the holes in the suction bed

cleaned the curved stainless steel bed

added more suction to the printed jobs

it seams that its gathering under the heater, ive put my hand under it I can't feel any glue there, but its hard to reach.

Its ok if I use the take up, but ive been running 1m prints without the take up not problem for years.

Its the same material as I always run.

not sure what else to try !