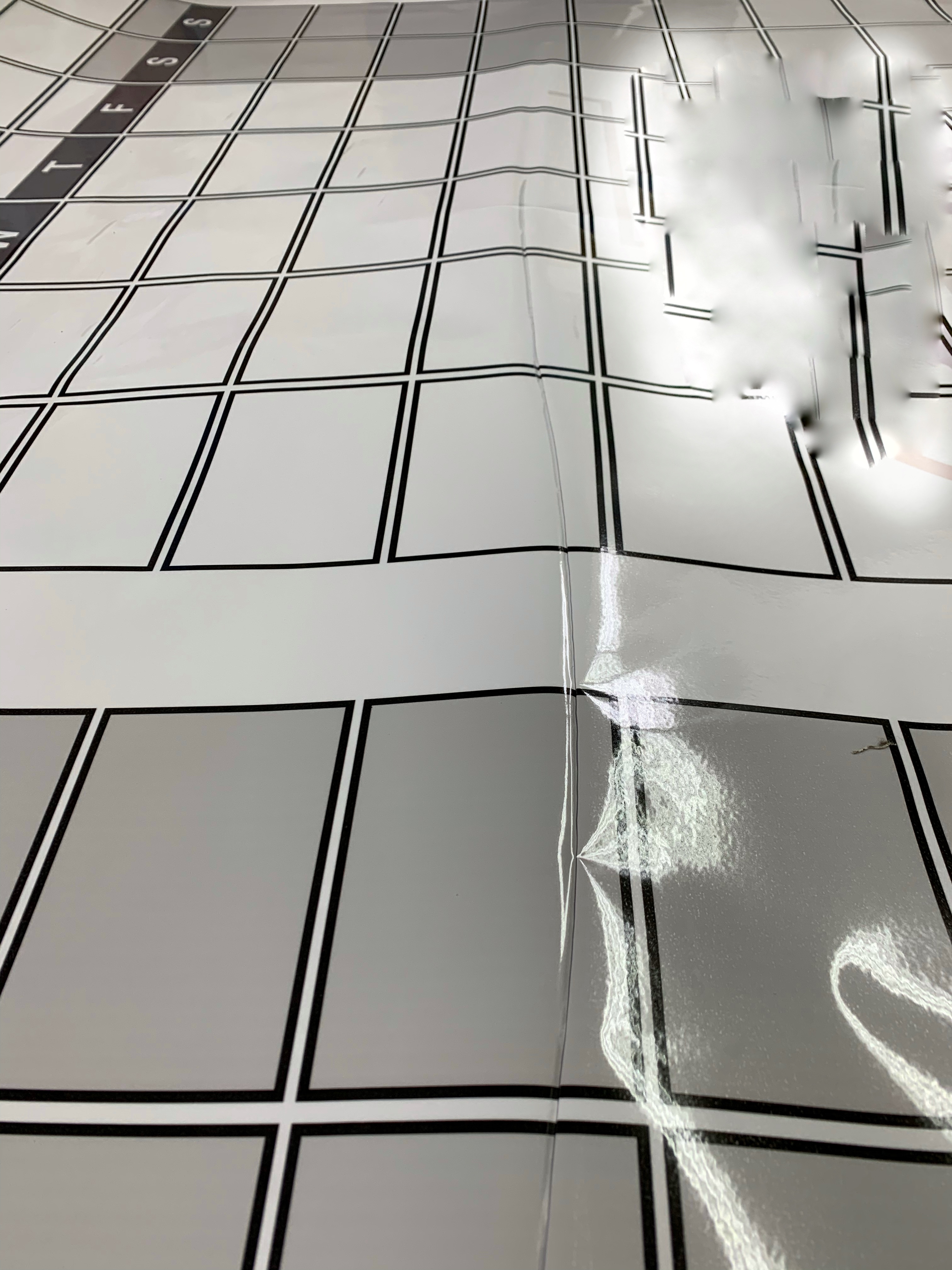

We run our prints on a Hp Latex. About 15 mins after running the prints, we run the vinyl through a RS cold laminator. The first foot or so laminates fine. After the first foot, the laminate wrinkles down the middle of the print.

Just wondering if anyone has any suggestions on what might be causing this.

Just wondering if anyone has any suggestions on what might be causing this.