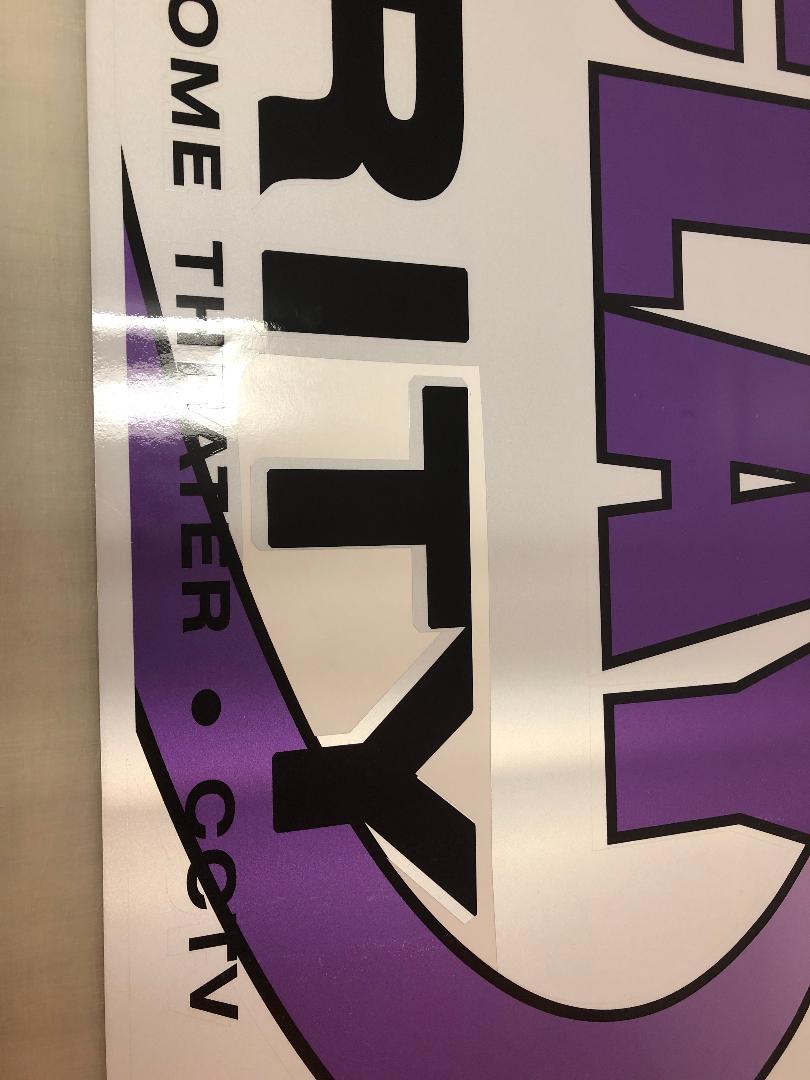

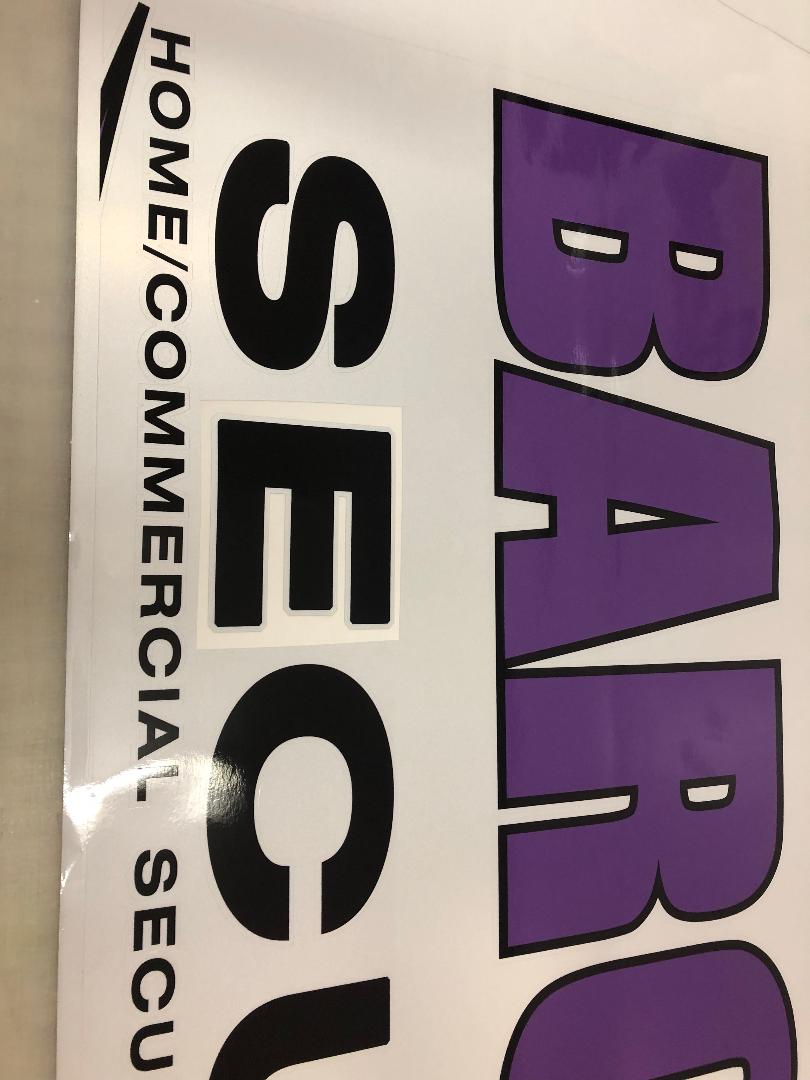

My Roland XR-640 is having an odd issue in the print and cut process. I've had some alignment issues down the road but nothing like this. I've printed a 60"x23" graphic on nikkalite reflective, then laminated it. This process using this same file has been done plenty of times, but now the forward side of the graphic is cut perfectly, and the rear side is cut off by nearly .25 inch. I've printed the graphic twice and tried cutting both but this has yielded the same poor results. Thanks for any help in advance!

-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need Help Roland XR-640 Print and Cut issues

- Thread starter Chase38

- Start date

rjssigns

Active Member

Could be any number of things. Are you absolutely sure the leading edge is perfectly perpendicular to the edge of the material? Using the sheet cut function does not make a square cut.

Are you using all the pinch wheels? How old are the pinch wheels, especially the two outside ones. They are tapered to pull the material flat and keep it in line.

Have you done a lot of printing? Cut carriage and other cables are consumable. Had that issue with mine

Encoder sensor can cause some issues too. Mine started to skew the prints, but didn't ruin the resolution. Skewed enough that even though it would read the crop marks it couldn't compensate when cutting.

Last thing is Roland print/cut devices ain't too swift in the cutting dept. Put up with mine for years with workarounds, and lots of ruined material. Finally bought a Summa. Now I can load a big job and walk away.

Are you using all the pinch wheels? How old are the pinch wheels, especially the two outside ones. They are tapered to pull the material flat and keep it in line.

Have you done a lot of printing? Cut carriage and other cables are consumable. Had that issue with mine

Encoder sensor can cause some issues too. Mine started to skew the prints, but didn't ruin the resolution. Skewed enough that even though it would read the crop marks it couldn't compensate when cutting.

Last thing is Roland print/cut devices ain't too swift in the cutting dept. Put up with mine for years with workarounds, and lots of ruined material. Finally bought a Summa. Now I can load a big job and walk away.

Roland Product Support

New Member

Hey Chase38,

All of the above ideas are relevant, but don't forget to update the printer firmware (which improves crop mark and feed functions).

Also, it's important to verify the problem is truly the printer hardware and not something else, such as the material itself. The following information will help you isolate the problem to its source.

Crop mark detection and/or cutting inaccuracy could be the result of the sensor being out of calibration, it could be a lighting issue in the room, it could even be a light reflection/glare issue with the lamination.

Try the following:

1) Print a job with crop marks and when it's finished printing, do NOT remove the media from the printer.

2) Use the UP arrow to reverse the media until the lead edge crop marks are positioned properly over the cutter protection strip.

3) Set the "base" point on the printer so when the printer scans for the marks, it does not advance the media.

4) Setup the software for "cut only" and send the job to the printer so it can detect the crop marks.

If the marks are not detected, or the cutting is offset of the print, the printer will require inspection and calibration.

However, if the job cuts spot on, then the problem is likely related to the laminate, or the way you're manually reloading the media after it's laminated.

Try reloading the media, being very careful that you're positioning the leading edge crop marks properly over the protection strip. Once you're 100% sure the material is loaded properly, try adjusting the lighting in the room to reduce reflection/glare that the sensor is likely detecting (even move the printer to another part of the room, if you have space to do so).

Try cutting again.

Ultimately if the problem continues, please call your Roland dealer and explain the details of the failure. They'll take over and resolve your issue.

Take care,

Roland Technical Support

All of the above ideas are relevant, but don't forget to update the printer firmware (which improves crop mark and feed functions).

Also, it's important to verify the problem is truly the printer hardware and not something else, such as the material itself. The following information will help you isolate the problem to its source.

Crop mark detection and/or cutting inaccuracy could be the result of the sensor being out of calibration, it could be a lighting issue in the room, it could even be a light reflection/glare issue with the lamination.

Try the following:

1) Print a job with crop marks and when it's finished printing, do NOT remove the media from the printer.

2) Use the UP arrow to reverse the media until the lead edge crop marks are positioned properly over the cutter protection strip.

3) Set the "base" point on the printer so when the printer scans for the marks, it does not advance the media.

4) Setup the software for "cut only" and send the job to the printer so it can detect the crop marks.

If the marks are not detected, or the cutting is offset of the print, the printer will require inspection and calibration.

However, if the job cuts spot on, then the problem is likely related to the laminate, or the way you're manually reloading the media after it's laminated.

Try reloading the media, being very careful that you're positioning the leading edge crop marks properly over the protection strip. Once you're 100% sure the material is loaded properly, try adjusting the lighting in the room to reduce reflection/glare that the sensor is likely detecting (even move the printer to another part of the room, if you have space to do so).

Try cutting again.

Ultimately if the problem continues, please call your Roland dealer and explain the details of the failure. They'll take over and resolve your issue.

Take care,

Roland Technical Support

I'm not sure which way you're running this through when you're cutting. A few months ago, the side-to-side (Scan direction) alignment on our Roland started to mess up in the middle of a print. It would start cutting okay and then get worse as the cut progressed. Cleaning the encoder strip solved the problem for us. I think the dirty strip wasn't being read perfectly as the head moved back and forth. When printing, the head returns to the home position after every pass, so problems caused by a dirty encoder strip aren't that bad. But when cutting, the head just stays out in the field the whole time. Little errors add up until the end of the cut is waaaaay off.

I love how the first response from Roland Tech Support is

I love how the first response from Roland Tech Support is

As much as I love our Roland printer, it drives my nuts that they always start by blaming everything but their printer. There are way too many little things that should be fixed and could be fixed if they would just stop blaming every other possible cause.to verify the problem is truly the printer hardware and not something else, such as the material itself.

Hollywoodsigns

Designer, printer

I agree with most of the responses, however I am having the same problem with my VG. Had a VS for 7 years and no problems. Did Crop/Cut alignment, cleaned Decoder strip, use 4 wheels, and put in a new cut strip. I also make sure the file is less than 2ft long. If it is longer than 3-4 ft I have had 0 success with this machine.

When it comes to making sure your spot on on loading. If your off a little bit. Is that not the reason there is 4 marks to read. The cut file will skew to the load? I know the straighter the better, but you would think it can be off a little bit. Just playing around with the Graphtec and put the media in very crooked on porpoise, worked out fine. I would use it more if I didn't have to print out of Flexi for Graphtec crop marks

When it comes to making sure your spot on on loading. If your off a little bit. Is that not the reason there is 4 marks to read. The cut file will skew to the load? I know the straighter the better, but you would think it can be off a little bit. Just playing around with the Graphtec and put the media in very crooked on porpoise, worked out fine. I would use it more if I didn't have to print out of Flexi for Graphtec crop marks