Dark Horse Signs

New Member

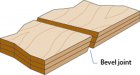

We seem to be having trouble always matching the seams up...seamlessly. Any thoughts, ideas, suggestions on how to match up PVC pieces or ACM panels on a wall while leaving an invisible seam? The thickness ranges from 3mm to 1in material.

This would have to be done without the design, if it was a solid colour piece.

We have tried using biscuits, it causes some improvement but cannot be used for thinner materials.

This would have to be done without the design, if it was a solid colour piece.

We have tried using biscuits, it causes some improvement but cannot be used for thinner materials.