trafficbarriersolutions

TRAFFIC & BARRIER SOLUTIONS, LLC

Hi,

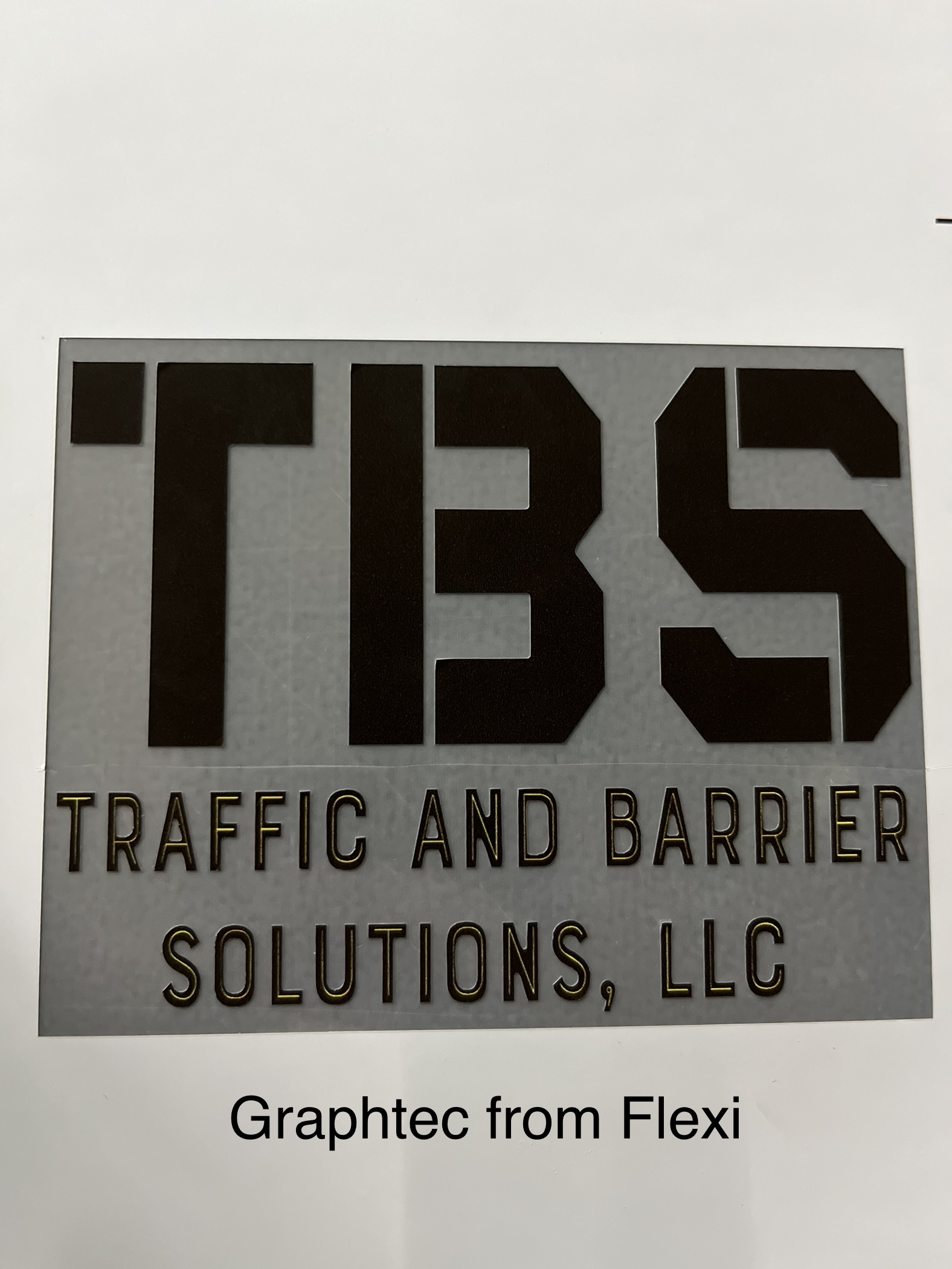

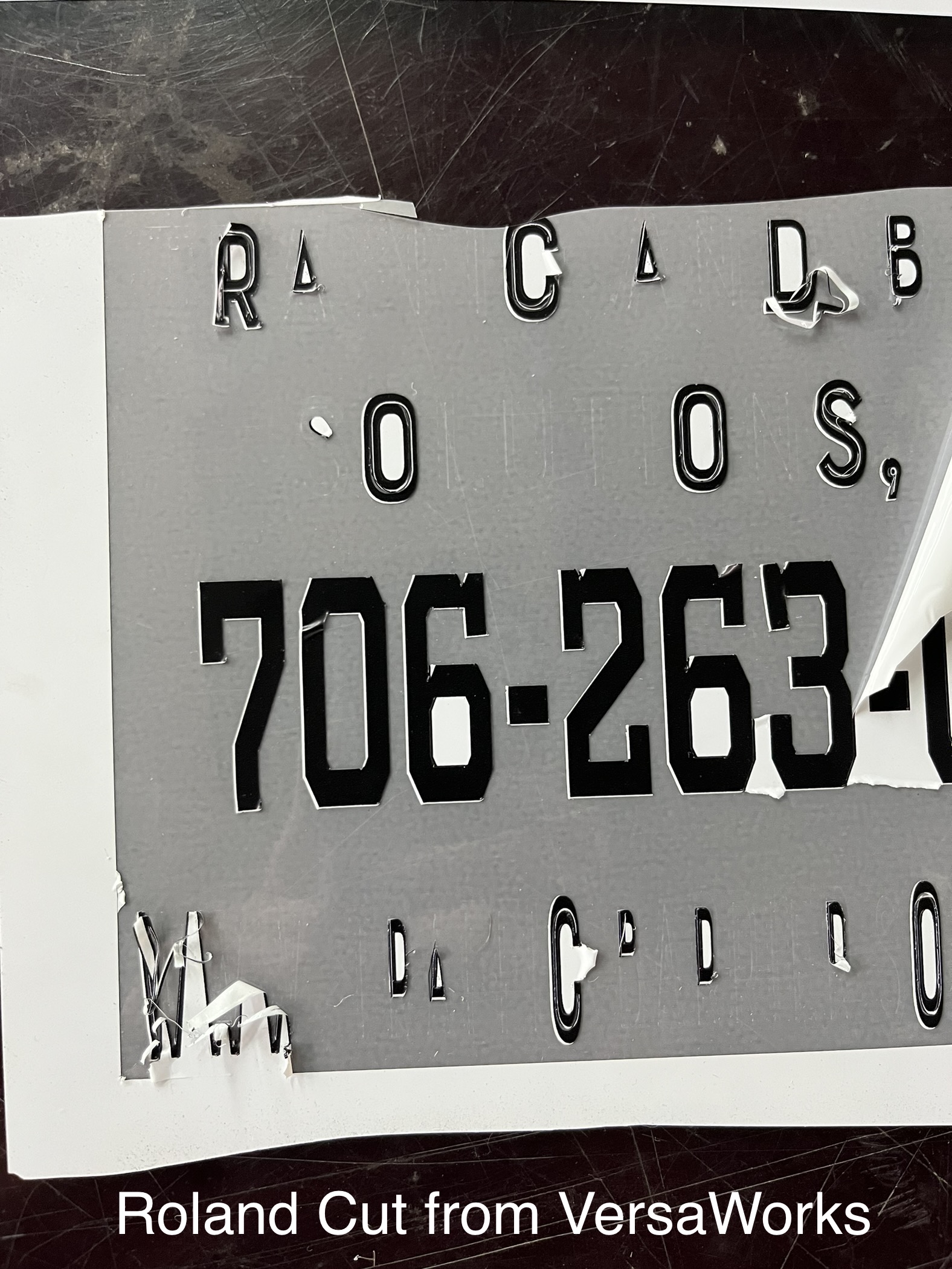

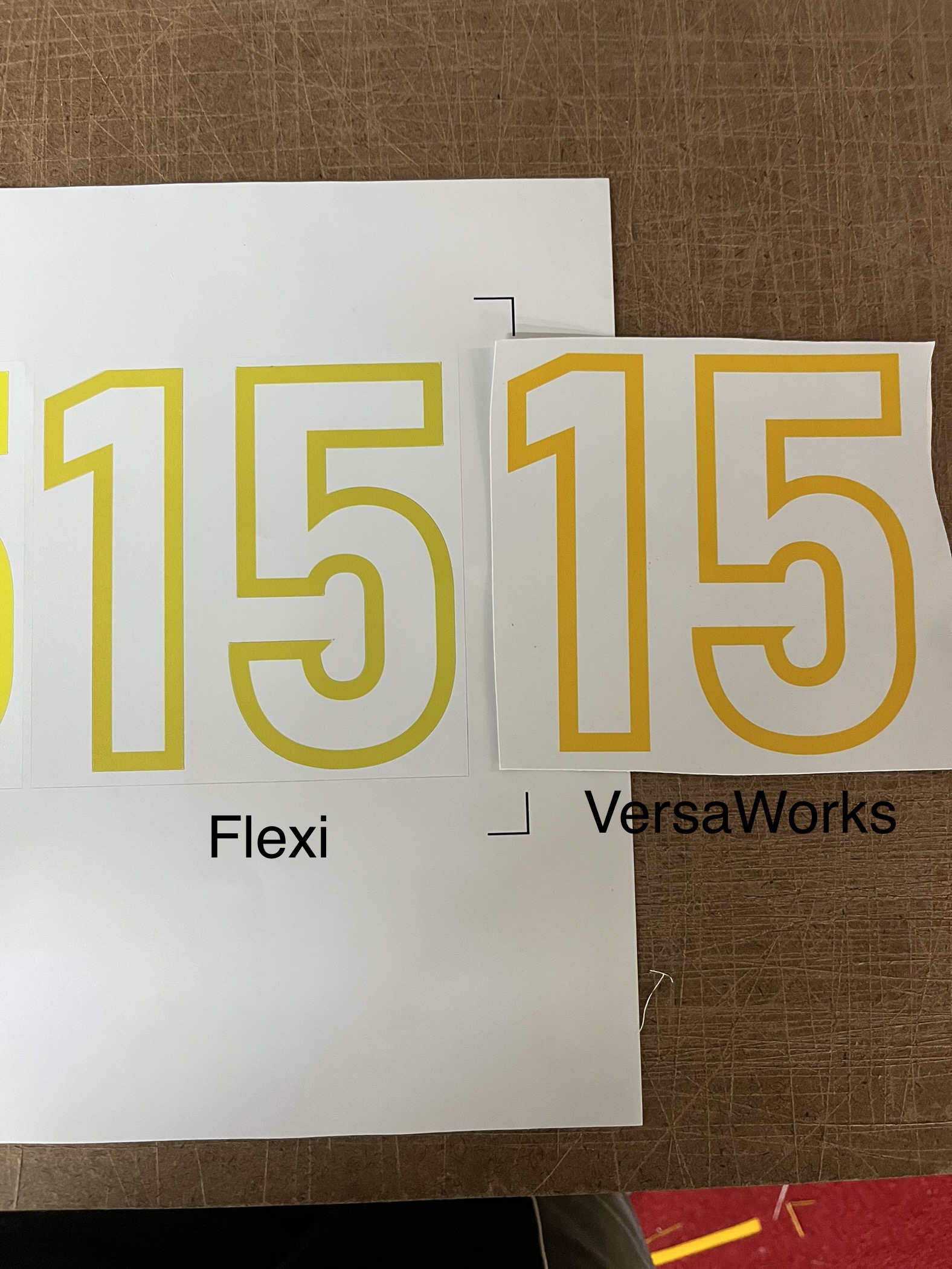

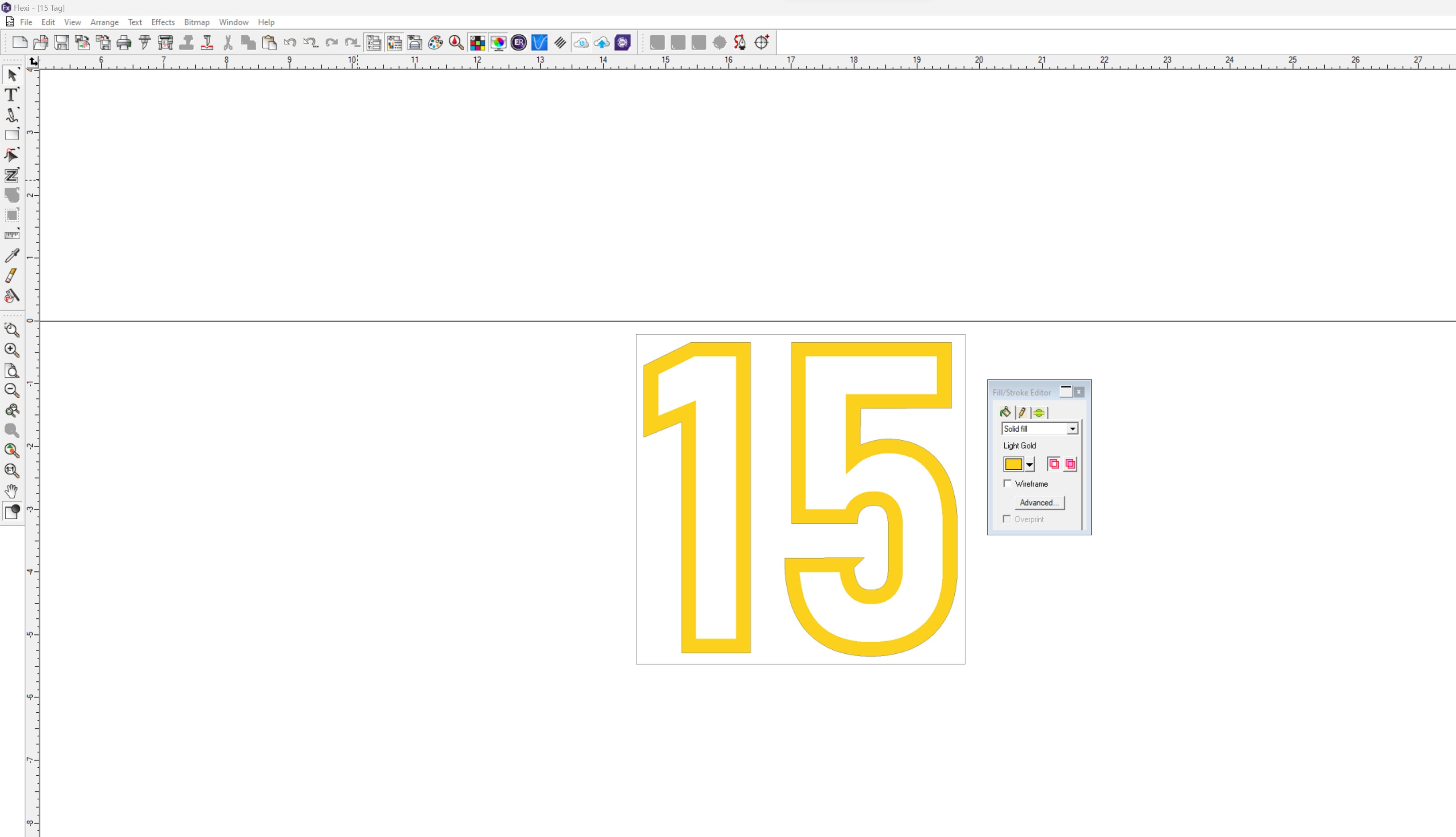

I am having trouble with my Roland printer when it comes to printing. It seems as though Flexi's Rip and Print software makes the Roland printer print incorrect colors. However, if I use my Graphtec to do my contour cutting, it is 100% correct. The opposite happens when I send it to VersaWorks, the colors are 100% correct, however, the cutting/plotting is incorrect on the Roland. Not only do I want my colors to be correct, but I also want my cutting/plotting to be correct. VersaWorks prints the colors correctly and my Graphtec plotter cuts correctly. Is there a way to connect my Graphtec to VersaWorks to send contour cuts. If VersaWorks is not compatible with Graphtec, is there a software that can not only help my Roland print correct colors, but also use my Graphtec for plotting?

I am having trouble with my Roland printer when it comes to printing. It seems as though Flexi's Rip and Print software makes the Roland printer print incorrect colors. However, if I use my Graphtec to do my contour cutting, it is 100% correct. The opposite happens when I send it to VersaWorks, the colors are 100% correct, however, the cutting/plotting is incorrect on the Roland. Not only do I want my colors to be correct, but I also want my cutting/plotting to be correct. VersaWorks prints the colors correctly and my Graphtec plotter cuts correctly. Is there a way to connect my Graphtec to VersaWorks to send contour cuts. If VersaWorks is not compatible with Graphtec, is there a software that can not only help my Roland print correct colors, but also use my Graphtec for plotting?