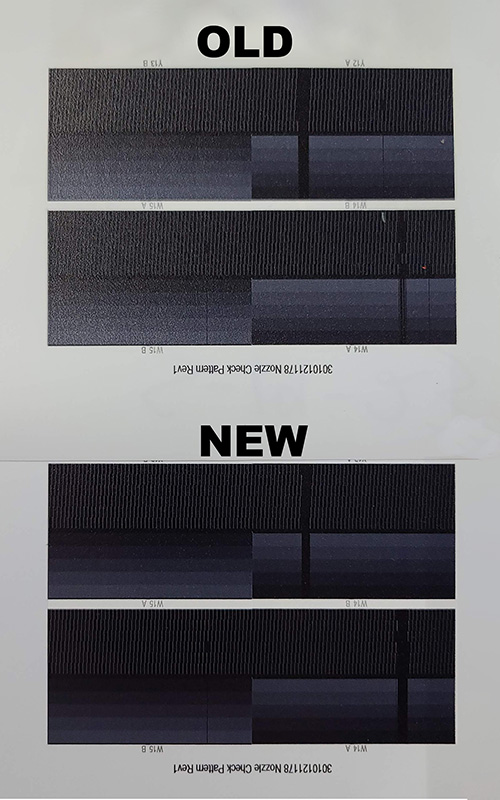

After a half a year of struggling with white inks we decided to replace the three most problematic white print heads on our Arizona 2280 (only 1 shown here). With some remote support we did the job ourselves, having never done it before it was moderately challenging but everything worked out just fine. The trouble is a main problem we thought we were fixing is still present. HOW!!!??? You can see in the image that these areas of missing nozzles are the same for the replaced print head and the new print head. The underside of the carriage is clean, no boogers of any kind, we are pretty clean shop and take care of things in general. Is this electrical? A ribbon cable? Something messed up on a board? We can get a 100% perfect nozzle test with some cleaning and purging. Also if it goes out mid job pressing the pause button and waiting a minute seems to get us back most of the time. I will get a tech in if I have to but I am hoping someone here has seen this before and can offer some insight.