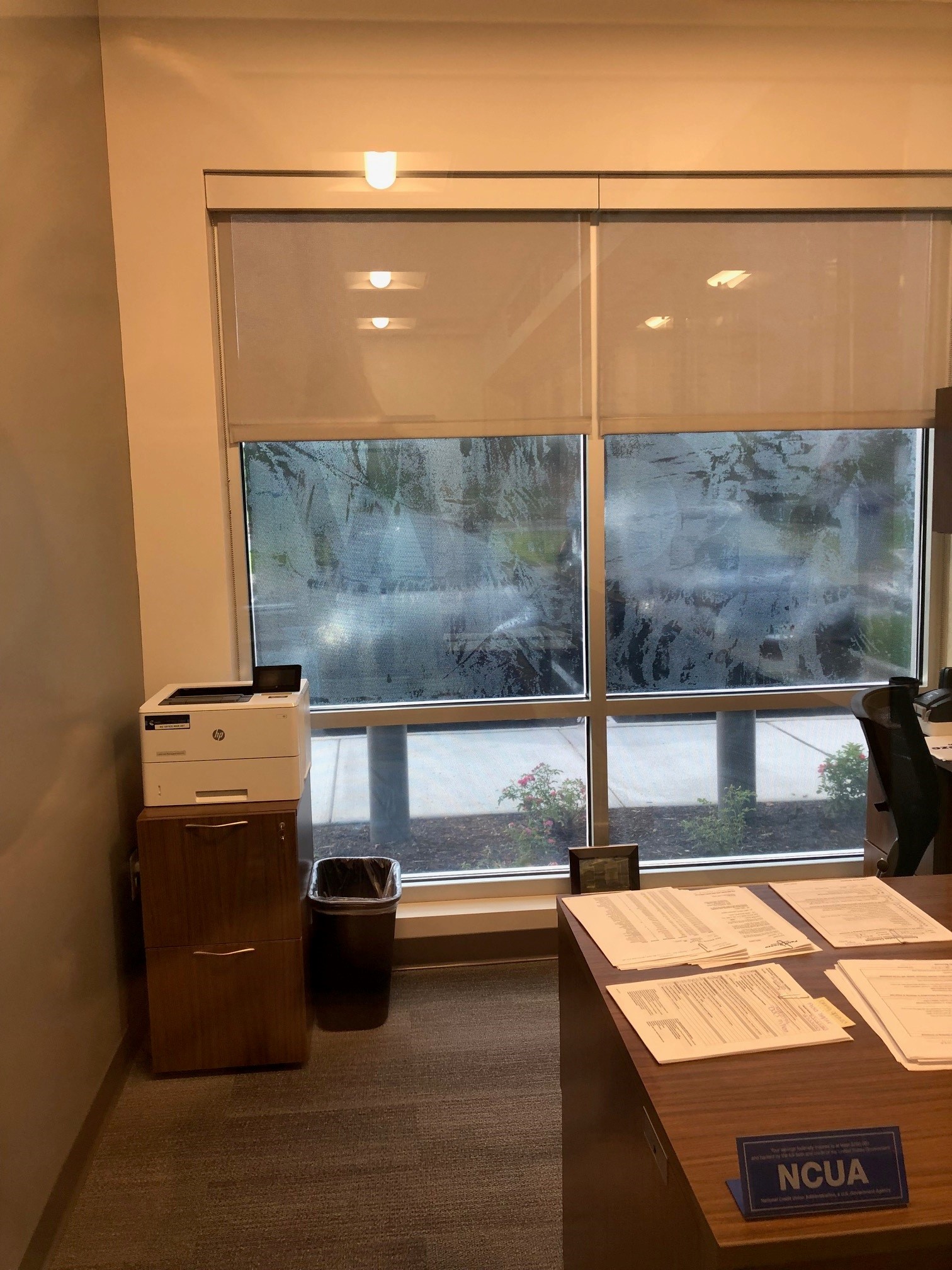

I have a job that called for 63/35 perf with optically clear laminate and when applied it looks awful. We certainly used optically clear and not 8518 for this as well. This is the second time installing and we used two different installers. Rest of the window perf looks 100% fine. I have a photo of what it looks like attached. Any help would be greatly appreciated!

Briteline 65/35 Perforated Vinyl

Clear Focus CurvaLam Overlaminate

Briteline 65/35 Perforated Vinyl

Clear Focus CurvaLam Overlaminate