Hello. I bought a UV printer CMYKWW. A3 size that uses 1 TX800 printhead. I have the same problem after changing the print head 3 times. White on the TX800 has 2 inputs, meaning 2 hoses and 2 dampers connected. One for spot and one for basic white printing. The issue seems to be the same for both spot and basic white printing. After some time of printing black for example, you start to print a solid white test square and it is not pure white. It is grayish. There have been times it was blue-ish as well. You must run clean routine which pulls ink out of printhead with a vacuum built in clean process. Then print some test white squares, clean again, print more tests until the white runs pure white. This has become a mandatory routine. You cannot just print something white without testing, and cleaning. I don't have drops leaking out on the table. This happened on other TX800 heads, which after they clog I replace with new and it's still not pure white ever until cleaning. I print direct to materials like plexi, metals, pilycarb etc. The material is not important to the problem,

Thanks for any tips.

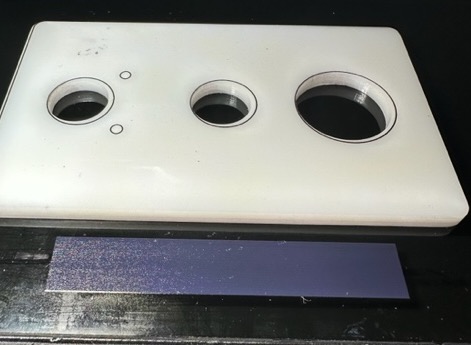

In the photos, I had just printed some black only ink for something. Then printed these solid white test rectangles. As you can see, 1 is gray, 2 is less gray, 3 and 4 start to become

white. This means I have to clean and run multiple tests every time before running a pure white print.The white plastic part is there just for white reference.

Thanks for any tips.

In the photos, I had just printed some black only ink for something. Then printed these solid white test rectangles. As you can see, 1 is gray, 2 is less gray, 3 and 4 start to become

white. This means I have to clean and run multiple tests every time before running a pure white print.The white plastic part is there just for white reference.