I figured I'd ask before I attempt a work around.... As this seems like something that shouldn't be happening.

Right now we have onyx printing barcodes on front and back, that way it doesnt matter if we laminate or not.

The F1612 will do the first barcode perfect... but then itll try to pick up the next barcode on the roll, but it'll read the line on the back end barcode and error out since the back end barcode and line is before the second barcode. So I have to set a new origin past the first barcode and run it again... kind of defeats the purpose of roll barcode..

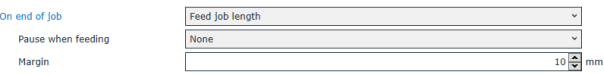

Am I missing something? I'm assuming some setting is just wrong somewhere... I have a feeling I can make a new action set that advances the media by an inch or two at the end of cutting to get rid of the issue, but I feel like thats the nuclear option. Do you guys just run with 1 barcode? or how do you get around it picking up the back end?

Right now we have onyx printing barcodes on front and back, that way it doesnt matter if we laminate or not.

The F1612 will do the first barcode perfect... but then itll try to pick up the next barcode on the roll, but it'll read the line on the back end barcode and error out since the back end barcode and line is before the second barcode. So I have to set a new origin past the first barcode and run it again... kind of defeats the purpose of roll barcode..

Am I missing something? I'm assuming some setting is just wrong somewhere... I have a feeling I can make a new action set that advances the media by an inch or two at the end of cutting to get rid of the issue, but I feel like thats the nuclear option. Do you guys just run with 1 barcode? or how do you get around it picking up the back end?