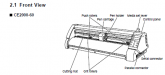

As I mentioned in a previous thread, we have a Graphtec CE2000-60 that we are trying to transition from one computer to another. After being unable to get satisfactory results from various software demos, we moved the cutter back to the original computer to try it with our old version of Flexi. We fed the same graphic to Flexi and SignGo and the results were pretty close to identical, indicating that there's a problem with the cutter itself. (It was physically moved across the office and has also probably never underwent any sort of maintenance in the past.)

As an experiment, we cut several copies of the same graphic, 5 wide and 2 deep, to see if problems occurred at certain locations. There was one very noticeable difference between the graphics across the horizontal access.

There is one portion that should be a very narrow strip. On the right side (where the cutting head rests when not in use), two cuts are very narrow at one end and quickly converge into a single line for a majority of the cut. Each subsequent image to the left is a bit wider in that area. On the far left copy of the image, the section is very clearly two cuts, the entire length of the piece, as it should be.

What would cause something like this to happen?

Edit: The software we were using when this issue occurred was SignGo. Also, I realized that it sounded like I was ignoring the possibility of the image itself having issues, but I presume those are the ones that are duplicated across multiple copies and that the image isn't at fault in the issue I described above.

As an experiment, we cut several copies of the same graphic, 5 wide and 2 deep, to see if problems occurred at certain locations. There was one very noticeable difference between the graphics across the horizontal access.

There is one portion that should be a very narrow strip. On the right side (where the cutting head rests when not in use), two cuts are very narrow at one end and quickly converge into a single line for a majority of the cut. Each subsequent image to the left is a bit wider in that area. On the far left copy of the image, the section is very clearly two cuts, the entire length of the piece, as it should be.

What would cause something like this to happen?

Edit: The software we were using when this issue occurred was SignGo. Also, I realized that it sounded like I was ignoring the possibility of the image itself having issues, but I presume those are the ones that are duplicated across multiple copies and that the image isn't at fault in the issue I described above.

Last edited: