Pearlljelly

Pearlljelly

I've been using my Graphtec FC9000 for a few months with zero issues, recently I have been getting a few off cuts.

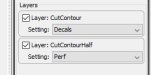

Software: Onyx Thrive and Cut Server (Up to date)

Blade: CB09UB-2

Printer: Epson R5070

Crop Marks: Inward facing L's

Here is my list of problems:

-Kiss cut likes to switch spots in the holder and will ruin a decal sheet by off cutting 1/4 inch forcing me to restart job or switch the tool to the perf holder

-Cuts will start off perfect in the beginning row and rows after that get thrown off migrating upwards

-Inconsistent cuts, print and cut doesn't line up.

-Makes a slight buzzing noise near left side

This is what I've been doing to help some of these problems:

-Attached a makeshift static kit (magnets and copper speaker wire to ground it)

-Did sensor offset adjust, turns out either perfectly aligned or 1/4 in off like previous jobs

-Looking into replacing blade cutter strip and belt

-Checked for bowing in the media, very minimal to none

-Replaced blade

-Cleaned out carriage incase double cut vinyl made its way in

-Had tech come in; re-aligned belt, adjusted tension, checked printer accuracy

-Marking edge of media with sharpie to line up the job as accurate as possible, running finger over middle crop marks to make sure they are in the perf cut hole

-Looking into switching software if that is an issue, possibly Flexi?

-Making sure pinch rollers are set in right position with right tension

We haven't had much luck with a tech, it seems no one in our area has really dealt with this kind of an issue.

Software: Onyx Thrive and Cut Server (Up to date)

Blade: CB09UB-2

Printer: Epson R5070

Crop Marks: Inward facing L's

Here is my list of problems:

-Kiss cut likes to switch spots in the holder and will ruin a decal sheet by off cutting 1/4 inch forcing me to restart job or switch the tool to the perf holder

-Cuts will start off perfect in the beginning row and rows after that get thrown off migrating upwards

-Inconsistent cuts, print and cut doesn't line up.

-Makes a slight buzzing noise near left side

This is what I've been doing to help some of these problems:

-Attached a makeshift static kit (magnets and copper speaker wire to ground it)

-Did sensor offset adjust, turns out either perfectly aligned or 1/4 in off like previous jobs

-Looking into replacing blade cutter strip and belt

-Checked for bowing in the media, very minimal to none

-Replaced blade

-Cleaned out carriage incase double cut vinyl made its way in

-Had tech come in; re-aligned belt, adjusted tension, checked printer accuracy

-Marking edge of media with sharpie to line up the job as accurate as possible, running finger over middle crop marks to make sure they are in the perf cut hole

-Looking into switching software if that is an issue, possibly Flexi?

-Making sure pinch rollers are set in right position with right tension

We haven't had much luck with a tech, it seems no one in our area has really dealt with this kind of an issue.

Last edited: