trafficbarriersolutions

TRAFFIC & BARRIER SOLUTIONS, LLC

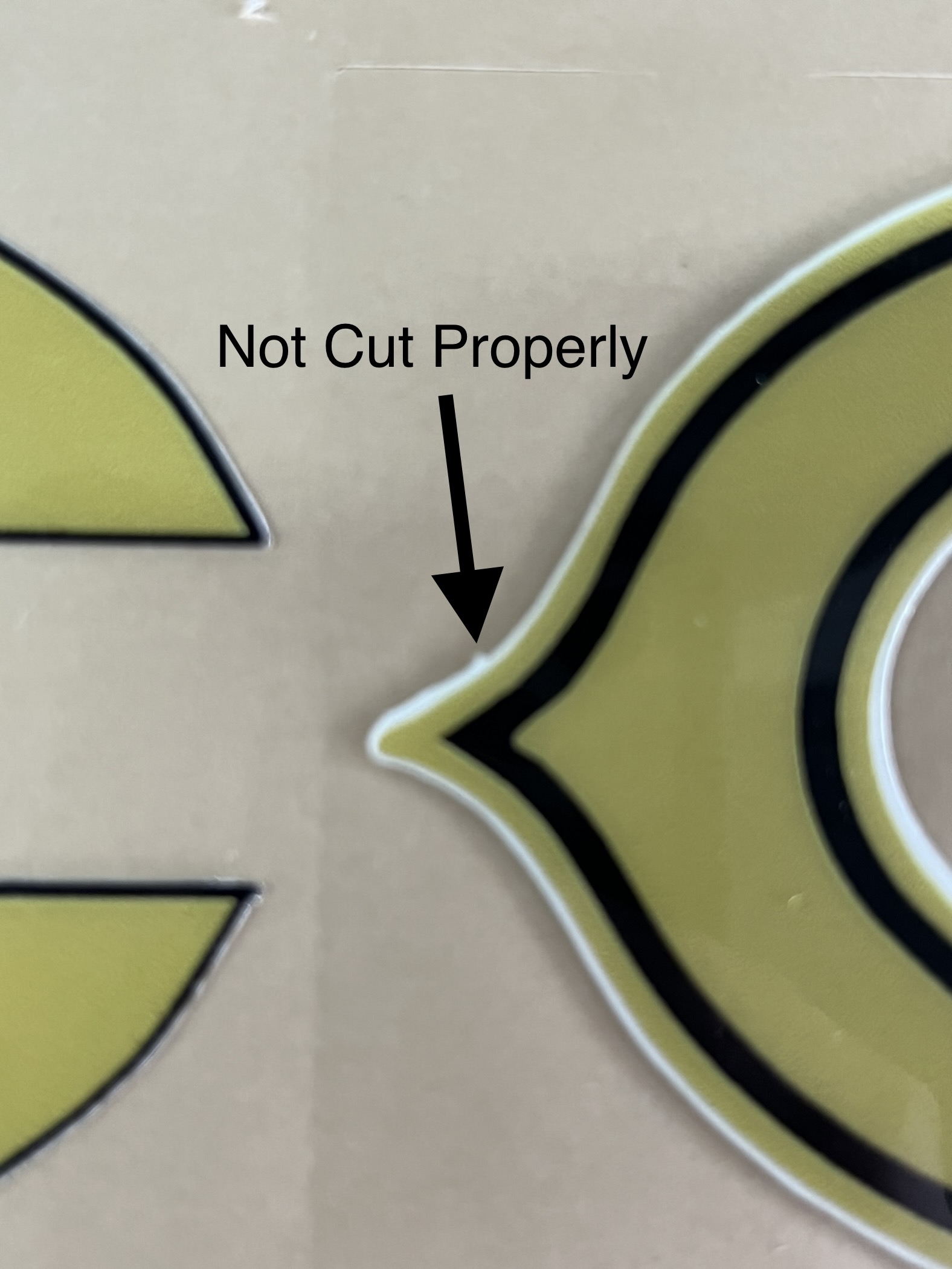

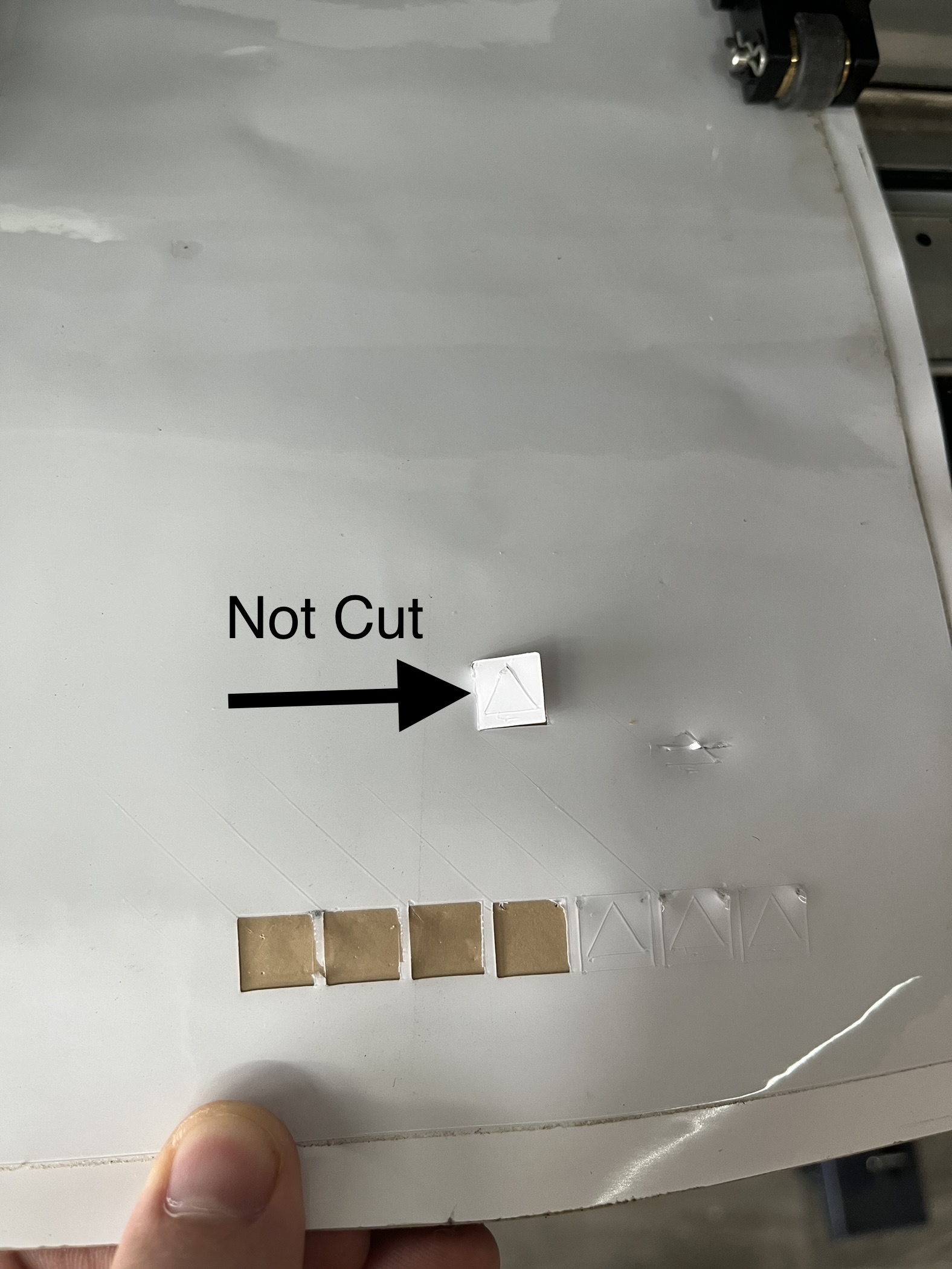

I am having an issue with my Graphtec FC-9000-140. It is cutting them deep enough in some spots. However, some areas are not deep enough when cutting out on the same job. The blade force is set at max and the depth is very deep and cut all the way through the vinyl a few times. The top knob has been twisted a lot clockwise to make the depth deeper. The vinyl I am cutting with is Substance Incorporated's ULTRACURVE H1 and ULTRACURVE 1500S Overlaminate. This material is made for Football Helmets, Construction Hard Hat Stickers, Baseball Batting Helmets, Dirt Bike Helmets, etc. The blade I have on the plotter is a 60 degree blade made for deeper thicker materials like Reflective Vinyls and Substance Inc ULTRACURVE H1 with ULTRACURVE 1500S Overlaminate. What is the issue with the plotter not cutting deep enough in some areas and deep enough in other areas?