I’m looking for a method of mounting the clear back of a fabricated aluminum halo letter to the letter itself. We used to use these small plastic tabs that we attached to the polycarbonate backs with rivets. We would then put a screw through the side of the letter into the tab and that would hold the letters together. We sourced the tabs from Gemini, but when we last tried to order them we were told they no longer carry them. I’ve just used up the last of my supply so I need a replacement product I can use going forward. What do you guys typically use for this?

-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scotchbrite

No comment

I understand the reasoning behind using clear plastic, I wonder if using small pieces of aluminum angle would work as well? At least for larger letters. Maybe small letters might show a shadow from the metal pieces. I have a sample letter from Gemini built that way.

James Burke

Being a grandpa is more fun than working

I've heard of female stand-offs, but never female studs. I believe the term contradicts itself....female stud.

A google search results in something totally different.

JB

James Burke

Being a grandpa is more fun than working

Well, daaaayum. I looked for myself. You're right.

JB

JB

Evan Gillette

New Member

Mcmaster has some plastic ones but not clear.

www.mcmaster.com

www.mcmaster.com

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Evan Gillette

New Member

I would look into UL catalog as that might give you the manufacturer (if its not actually gemini). I would take a look but don't have the time tonight, keep us posted if you find them, they are useful. Maybe put a call into MBS standoffs, they have really been stepping up their game.

I’ve seen metal ones on signs manufactured by other companies, they had tapped holes for studs and to attach to the letter itself. I haven’t been very successful in searching for them though.

We tried extruded placrylic angle, but our local supplier only carries one with too thin of a wall. Those McMaster carr ones might be a good alternative

We tried extruded placrylic angle, but our local supplier only carries one with too thin of a wall. Those McMaster carr ones might be a good alternative

signbrad

New Member

Gemini may have discontinued the acrylic brackets because of constant breakage. Switching to metal would have eliminated the problem.

When acrylic is machined, thousands of micro fissures occur along the edge of a cut or a drilled hole. They're practically invisible till you wipe with a lacquer thinner or some other hot solvent, or sometimes when you paint with a paint whose reducer has one or more of the lacquer thinners (toluene, xylene, etc). We have seen acrylic pieces develop significant margins of spidery cracks along a cut within minutes of painting the acrylic with polyurethane.

Even pinching acrylic can cause these stress fractures, pinching such as can possibly be caused by a pop rivet or a tightened screw. Engineers even have a name for the micro cracks caused by pinching acrylic—it's called creep.

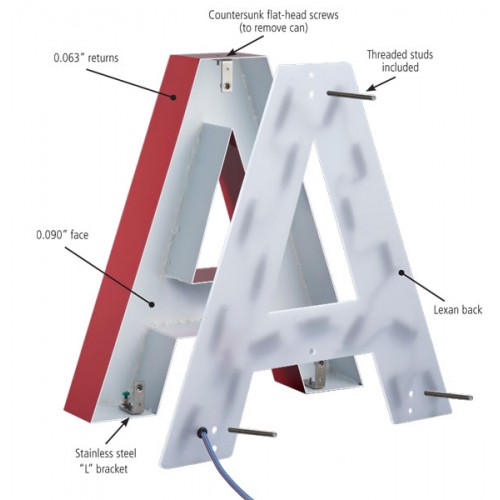

Riveting a metal bracket to the polycarbonate back of the halo-lit letter avoids the possibility of an acrylic bracket cracking from drilling and riveting. It also has the advantage that screws through the returns holding the fabricated letters to the brackets can be removed, allowing easy servicing of the LED modules which remain attached to the polycarbonate backer.

Note in the Gemini drawing that countersunk screws are depicted holding the channel letter to the brackets. A better choice is a truss head screw. It doesn't require a countersunk hole, but still has a nice low profile. A truss head is also a better choice than a hex head to attach trim cap.

Also, note that the drawing is showing a white plastic back rather than clear. Better light diffusion?

You will find that when acrylic breaks, it is often at a fastener. It's because the cracks are already there, just unseen. It's why drilling holes in acrylic is best avoided, if possible. If holes must be drilled into acrylic, the manufacturers' guidelines on hole diameter and distance of a hole from the edges of acrylic should be followed to minimize breakage.

Even the pressure exerted by a "knob-type" standoff can, over time, result in creep, allowing a corner to break off a sign panel from just normal wiping. Finger tighten the cap then back off one quarter is a common rule of thumb.

For generations, acrylic faces have been installed using retainers only, with no fasteners penetrating the plastic, and with good reason. You can get away with putting screws in the corners of a polycarbonate face, but not in an acrylic face.

Failure from damage caused by creep occurs not just in plastics, but metal as well.

Brad in Kansas City

When acrylic is machined, thousands of micro fissures occur along the edge of a cut or a drilled hole. They're practically invisible till you wipe with a lacquer thinner or some other hot solvent, or sometimes when you paint with a paint whose reducer has one or more of the lacquer thinners (toluene, xylene, etc). We have seen acrylic pieces develop significant margins of spidery cracks along a cut within minutes of painting the acrylic with polyurethane.

Even pinching acrylic can cause these stress fractures, pinching such as can possibly be caused by a pop rivet or a tightened screw. Engineers even have a name for the micro cracks caused by pinching acrylic—it's called creep.

Riveting a metal bracket to the polycarbonate back of the halo-lit letter avoids the possibility of an acrylic bracket cracking from drilling and riveting. It also has the advantage that screws through the returns holding the fabricated letters to the brackets can be removed, allowing easy servicing of the LED modules which remain attached to the polycarbonate backer.

Note in the Gemini drawing that countersunk screws are depicted holding the channel letter to the brackets. A better choice is a truss head screw. It doesn't require a countersunk hole, but still has a nice low profile. A truss head is also a better choice than a hex head to attach trim cap.

Also, note that the drawing is showing a white plastic back rather than clear. Better light diffusion?

You will find that when acrylic breaks, it is often at a fastener. It's because the cracks are already there, just unseen. It's why drilling holes in acrylic is best avoided, if possible. If holes must be drilled into acrylic, the manufacturers' guidelines on hole diameter and distance of a hole from the edges of acrylic should be followed to minimize breakage.

Even the pressure exerted by a "knob-type" standoff can, over time, result in creep, allowing a corner to break off a sign panel from just normal wiping. Finger tighten the cap then back off one quarter is a common rule of thumb.

For generations, acrylic faces have been installed using retainers only, with no fasteners penetrating the plastic, and with good reason. You can get away with putting screws in the corners of a polycarbonate face, but not in an acrylic face.

Failure from damage caused by creep occurs not just in plastics, but metal as well.

Brad in Kansas City

bowtievega

Premium Subscriber

We used 3/4" x 1/16" wall alum angle for a long time. Put an 8-32 riv nut on one side for attaching the RPC letter to the clip. We put a couple 1/8" rivets thru the clip and the polycarbonate letter back. Works great. Currently we custom cut a batch of .040" alum pieces on the router that have bend marks and pre-drilled mounting screw holes. They are tabbed together next to each other so we can bend a bunch at one time then bandsaw the pieces of of the extra material. They have a smaller foot print and are pretty cheap to make if you do a bunch at once. Still use 3/4" or 1" angle for larger letters that need a more substantial mounting method. We use polycarbonate for all of our letter backs, not acrylic. Mostly clear but we have experimented with white light diffusing polycarb as well to try and cut down on letter reflections when mounted to smooth painted faces. I found it really doesn't fix the issue and lets a little less light thru. Sanding the back of the clear backer with 220 grit sandpaper does a pretty good job of diffusing light as well.