Mike Brice

New Member

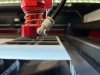

Does anyone have issues with soot accumulating on the tip of their laser head?

We have Boss Laser 150w CO2 using a 2" lens. We use LASERMAX rowmark for all engraving jobs.

The job shown in the pictures took 12 mins @ 350/16 .05 line interval. I was advised during training with Boss not to use air assist when engraving & to premask to reduce burn marks on the material.

I had to pause the job once to wipe the tip as the laser was starting to lose power. I'm also seeing a lot of buildup on the lens itself rather quickly & I'm often cleaning the lens multiple times a day.

This is becoming so inefficient.

We have Boss Laser 150w CO2 using a 2" lens. We use LASERMAX rowmark for all engraving jobs.

The job shown in the pictures took 12 mins @ 350/16 .05 line interval. I was advised during training with Boss not to use air assist when engraving & to premask to reduce burn marks on the material.

I had to pause the job once to wipe the tip as the laser was starting to lose power. I'm also seeing a lot of buildup on the lens itself rather quickly & I'm often cleaning the lens multiple times a day.

This is becoming so inefficient.