Hello everyone! A few months ago, I purchased a VS540 (my first large-format printer after using a BN20), and recently, I've been facing some major issues that are seriously affecting my business. Any help or advice would be greatly appreciated !

We purchased this used Roland VS540 printer about 4 months ago. After reconditioning it, we didn't encounter any problems during its operation. We print exclusively on Oracal monomeric vinyl.

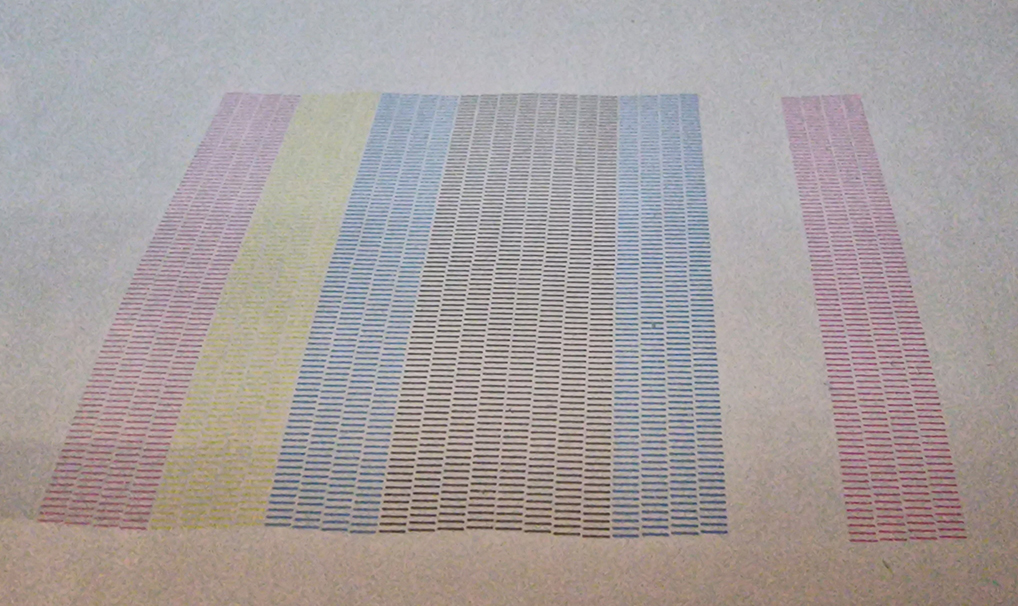

The printer was left unused for approximately three weeks, but we kept it plugged in and performed regular cleaning and test prints. Suddenly, the second yellow channel (8-cartridge CYMK configuration) stopped working. Please see the attached photo :

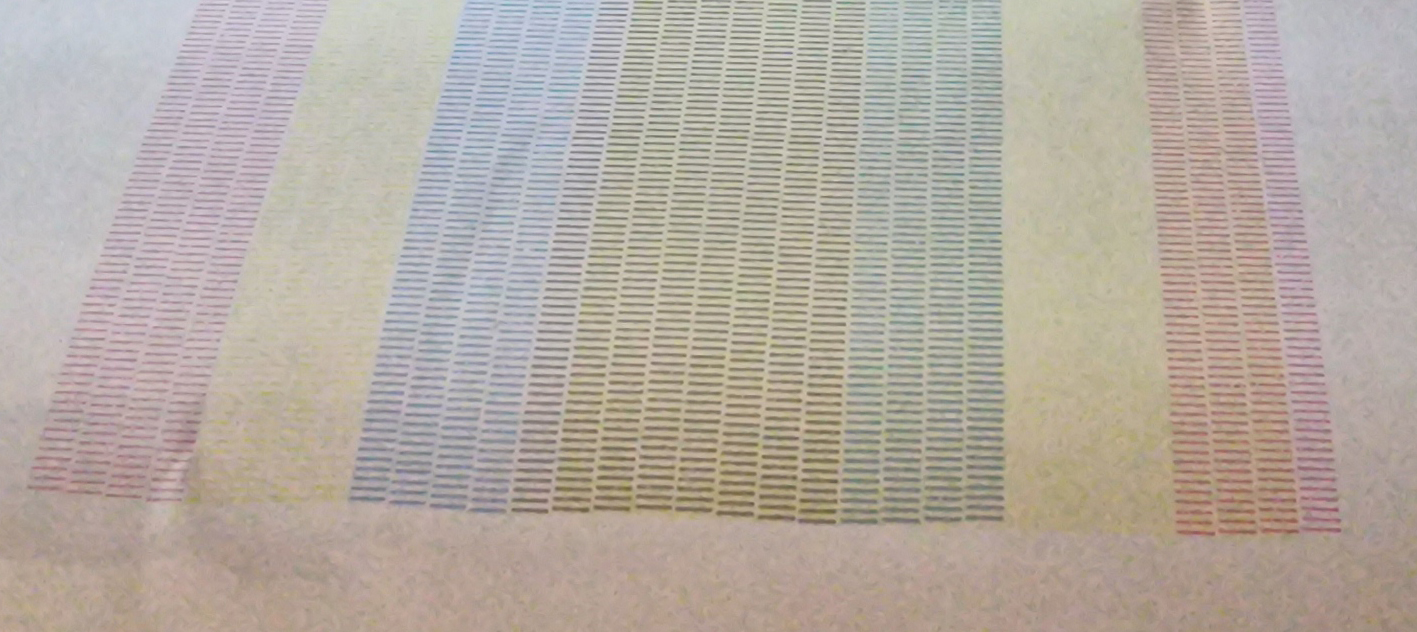

Despite this issue, prints made through VersaWorks seemed fine, but occasionally, yellow would cover the prints.

Please see the attached photo:

After completely restarting the printer, this phenomenon seemed to disappear (returning to the result of the first attached picture), except for the clogged yellow channel, which did not improve.

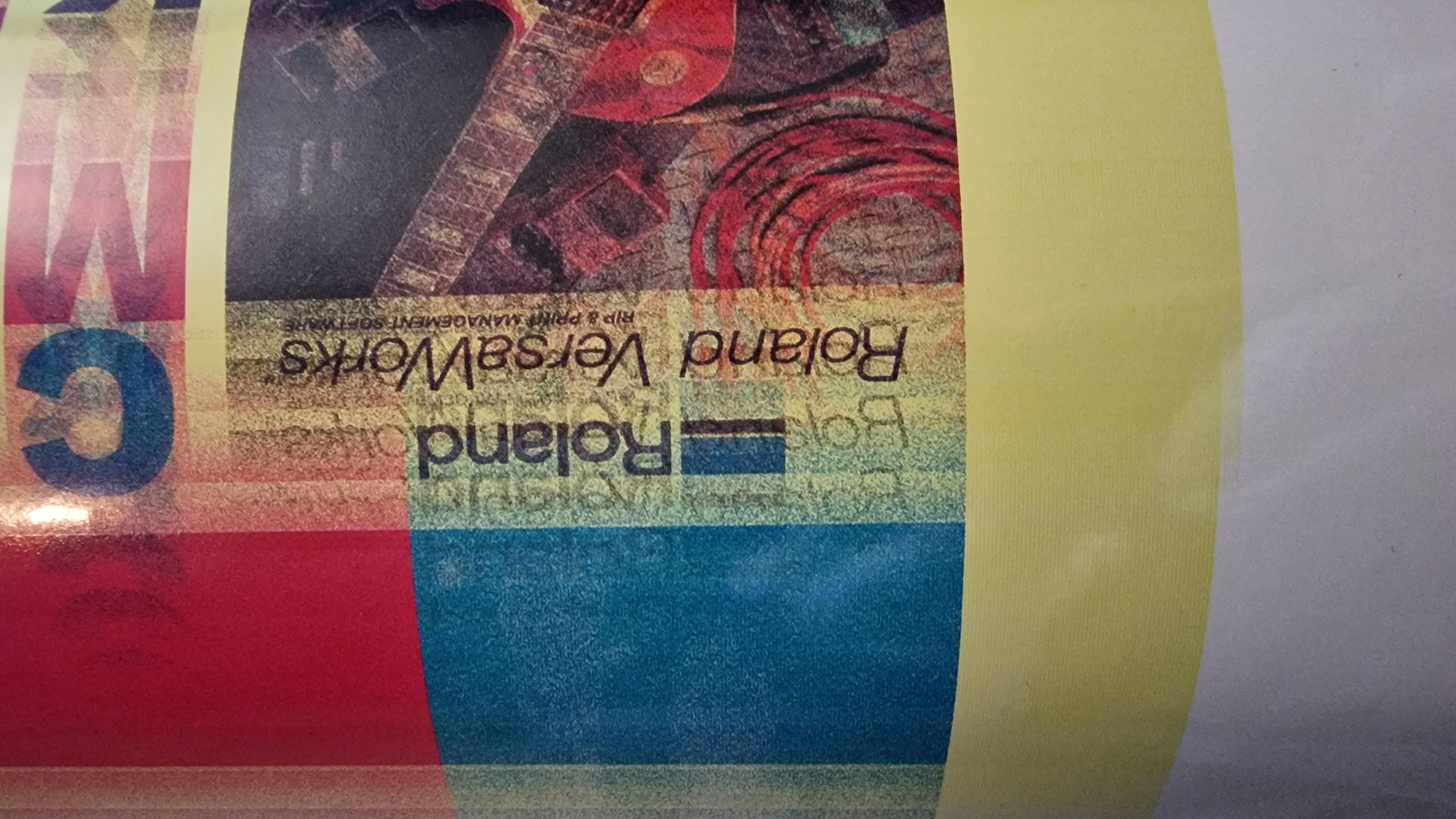

Two days after noticing this issue, another problem emerged ! a complete misalignment of the prints and a mirrored overprint effect. This issue occurs in both unidirectional and bidirectional printing, regardless of the chosen print profile.

Two days after noticing this issue, another problem emerged ! a complete misalignment of the prints and a mirrored overprint effect. This issue occurs in both unidirectional and bidirectional printing, regardless of the chosen print profile.

Here's what we've tried without success:

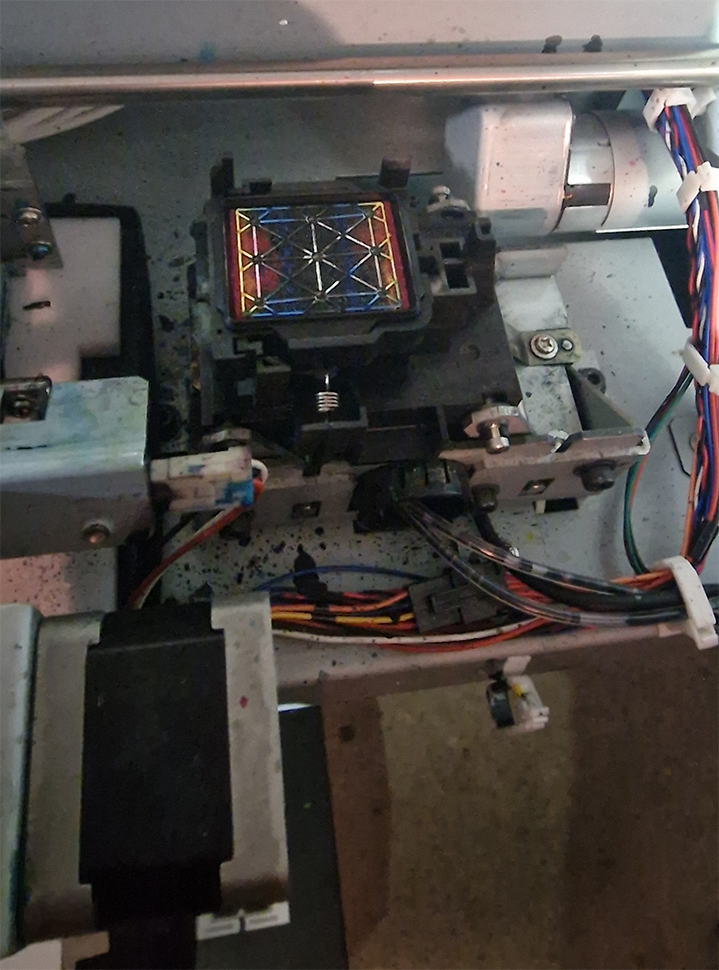

We also checked if the ink from the faulty yellow channel was reaching the damper (by drawing it up with a syringe on the inlet tube to the damper and through the captop). See the photo of the new captop after the first cleaning:

The parts we have replaced due to this issue are:

here's atached a CoPeck Report (i dont have any program to read it myself unfortunnaly) : https://mega.nz/file/KVlE3Y7C#_nNGr3nTsmUi3qcHIzF2XvTskZmg7YNgZwt2BE1yqnw

I would greatly appreciate any help or suggestions to resolve this issue. Thank you in advance for your assistance !

We purchased this used Roland VS540 printer about 4 months ago. After reconditioning it, we didn't encounter any problems during its operation. We print exclusively on Oracal monomeric vinyl.

The printer was left unused for approximately three weeks, but we kept it plugged in and performed regular cleaning and test prints. Suddenly, the second yellow channel (8-cartridge CYMK configuration) stopped working. Please see the attached photo :

Despite this issue, prints made through VersaWorks seemed fine, but occasionally, yellow would cover the prints.

Please see the attached photo:

After completely restarting the printer, this phenomenon seemed to disappear (returning to the result of the first attached picture), except for the clogged yellow channel, which did not improve.

Two days after noticing this issue, another problem emerged ! a complete misalignment of the prints and a mirrored overprint effect. This issue occurs in both unidirectional and bidirectional printing, regardless of the chosen print profile.

Two days after noticing this issue, another problem emerged ! a complete misalignment of the prints and a mirrored overprint effect. This issue occurs in both unidirectional and bidirectional printing, regardless of the chosen print profile.Here's what we've tried without success:

- Multiple cleanings (light, medium, and heavy)

- Two head soakings for 6 hours and 48 hours

- Choke cleaning through the service menu

- Replacing the cartridge for the affected channel

- Cleaning and calibrating the encoder strip

We also checked if the ink from the faulty yellow channel was reaching the damper (by drawing it up with a syringe on the inlet tube to the damper and through the captop). See the photo of the new captop after the first cleaning:

The parts we have replaced due to this issue are:

- Captop and its pump (ref: 6701409200 & ref: 6000005297)

- Replacing all four head cables (3x ref: 1000006702 and 1x ref: 1000006703)

- Replacing the ink cartridge for the faulty channel (i'm using STS inks)

here's atached a CoPeck Report (i dont have any program to read it myself unfortunnaly) : https://mega.nz/file/KVlE3Y7C#_nNGr3nTsmUi3qcHIzF2XvTskZmg7YNgZwt2BE1yqnw

I would greatly appreciate any help or suggestions to resolve this issue. Thank you in advance for your assistance !

Last edited: