TopFliteGraphics

New Member

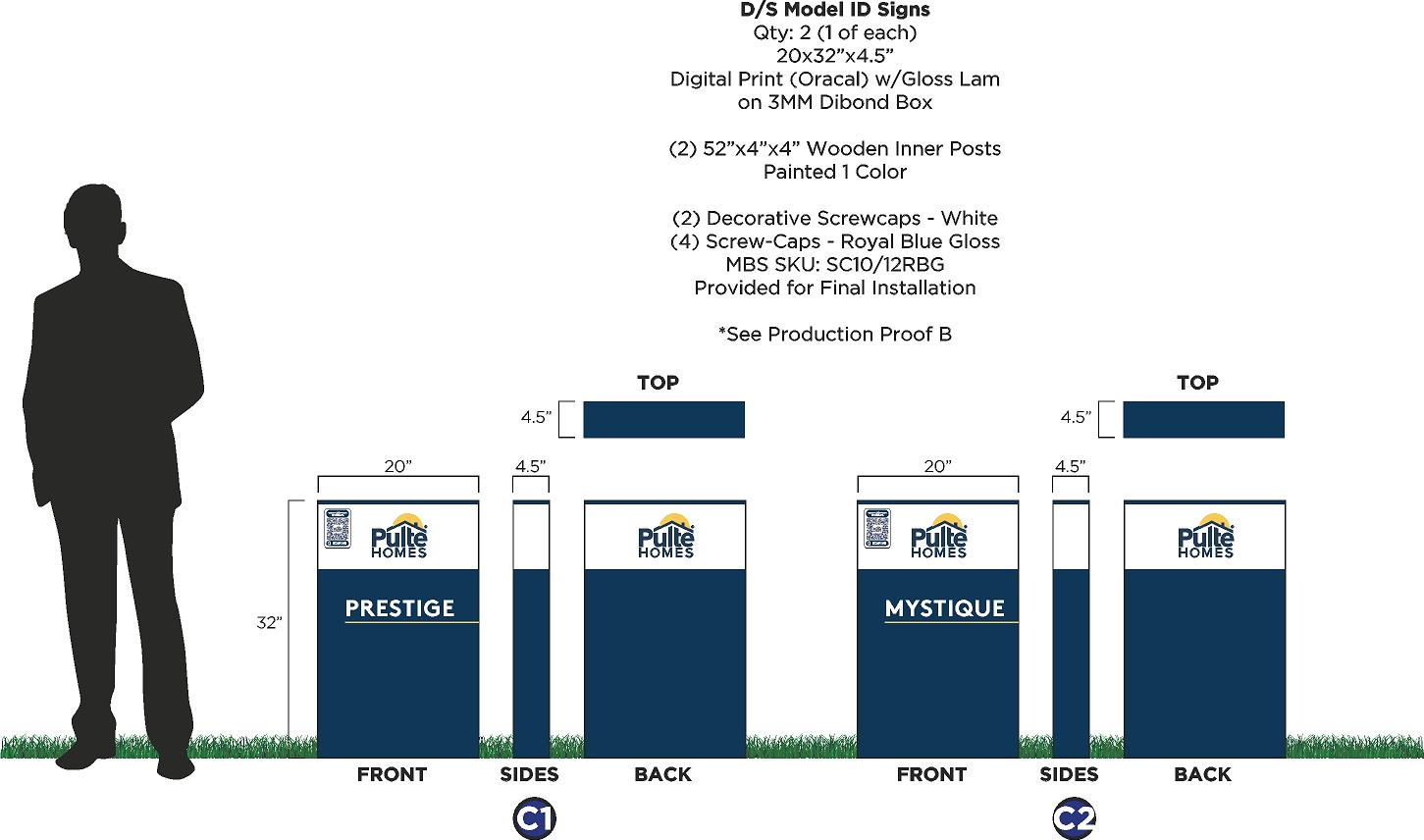

One of my customers sent me this to quote with no detail. I have a few ideas on how to build it but I figured I would ask the group what you would do to make these. I make something similar for another client using 1/2" PVC but they are calling for 3mm dibond boxes.

Let me know your ideas. Thanks, Gary

Let me know your ideas. Thanks, Gary