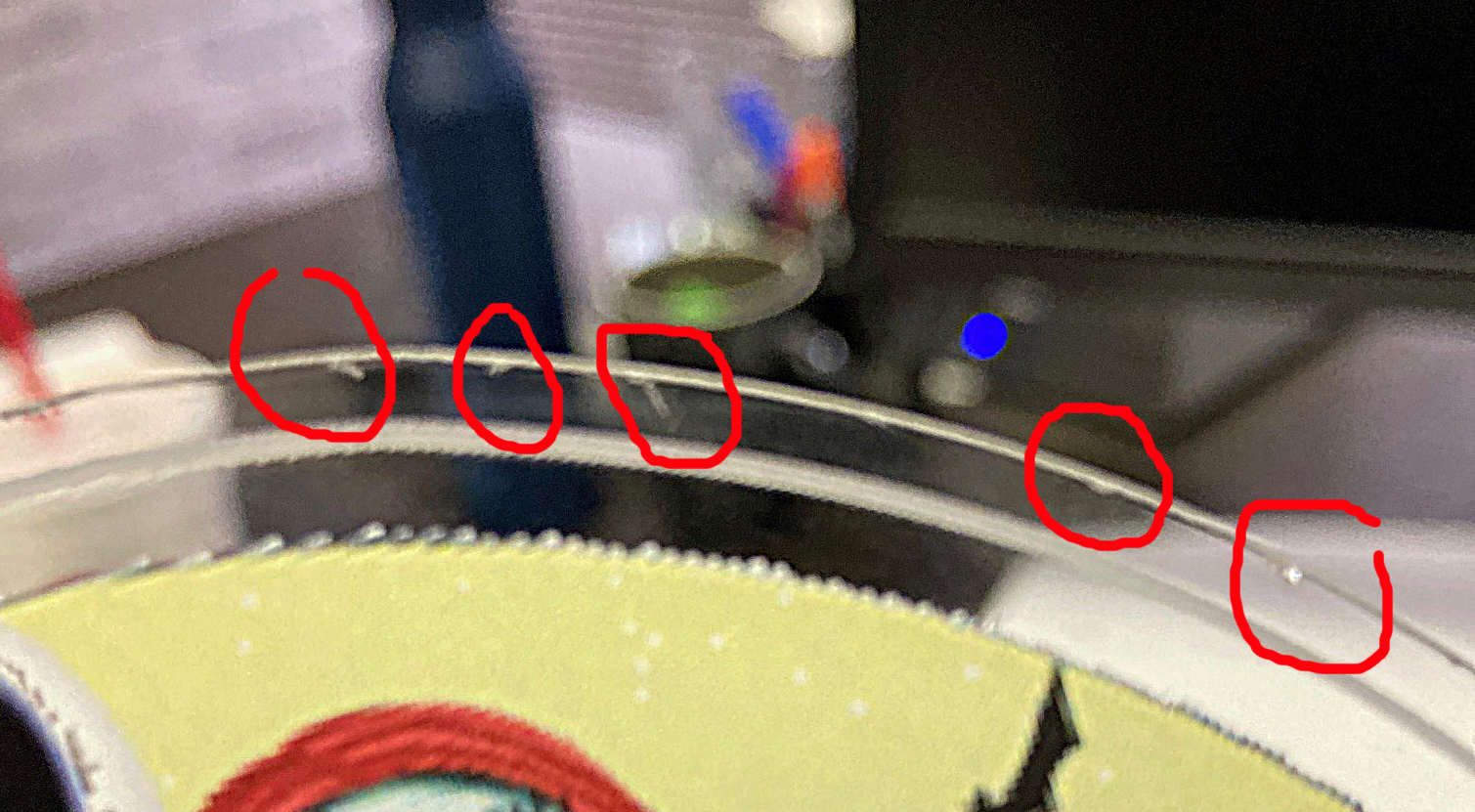

We are new to laser cutting and are still learning. We have a Boss CO2 laser. On the most recent project, we have what i describe as "pitting". It is little chips of the acrylic getting knocked out of the back of the cut. Anyone know what might be causing this? It is hard to get a good photo since they are so small and my phone wouldn't let me get that close. I've circled some in red. Any help or advice would be greatly appreciated.

-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CanuckSigns

Active Member

You can also purchase acrylic honeycomb instead of the metal, this will eliminate the issue.

VizualVoice

I just learned how to change my title status

if you're like me and get whacky ideas to try and see the grid pattern fluorescent ceiling light diffuser panels at Lowes or Home Depot and think "hey I bet I can use that as an acrylic honeycomb because it's way cheaper", I'll save you the trouble of finding out yourself that your pieces will wind up stuck to it when it melts from the laser beam.

Hmm.. never thought of acrylic honeycomb.You can also purchase acrylic honeycomb instead of the metal, this will eliminate the issue.

What thickness is it / where do you buy it from? How long does it last?

I do a ton of acrylic these days and I cover the table with wypall and spray it with water... It works but is a pain, having an acrylic honeycomb I can just drop on-top of my existing one would speed things up.

I guess you could cut your own in theory - might try to cut a honeycomb pattern out of quarter inch... Since it's just going on-top of my old honeycomb it might be thick enough.

CanuckSigns

Active Member

I've always cut them from 0.25" thick acrylic. But I think some people use those plastic grids used in fluorescent light fixtures as a diffuser.Hmm.. never thought of acrylic honeycomb.

What thickness is it / where do you buy it from? How long does it last?

I do a ton of acrylic these days and I cover the table with wypall and spray it with water... It works but is a pain, having an acrylic honeycomb I can just drop on-top of my existing one would speed things up.

I guess you could cut your own in theory - might try to cut a honeycomb pattern out of quarter inch... Since it's just going on-top of my old honeycomb it might be thick enough.

I bought a pack of 100 golf tees and I usually throw them in the honeycomb, it raises it off the bed by about a quarter inch. Not bad for bigger parts... but I have 300 2"x6" Acyrlics to cut, and I'm not putting 500 golf tees in. I'll cut a sheet of quarter inch out and give it a test - As long as it doesnt warp from the heat, which I imagine it'll be getting very little heat it should work good.

I was thinking of buying a sheet of the protective acyrlic that Co2 Lasers cant go through... CNC out a honeycomb pattern, and theoretically it'd last forever. I havent found a good supplier in Canada that sells it for under a grand a sheet though...

I was thinking of buying a sheet of the protective acyrlic that Co2 Lasers cant go through... CNC out a honeycomb pattern, and theoretically it'd last forever. I havent found a good supplier in Canada that sells it for under a grand a sheet though...

let's talk acrylic.... the laser can't go through it? - meaning the laser light is fully absorbed, right?... then the laser will cut through the acrylic.I bought a pack of 100 golf tees and I usually throw them in the honeycomb, it raises it off the bed by about a quarter inch. Not bad for bigger parts... but I have 300 2"x6" Acyrlics to cut, and I'm not putting 500 golf tees in. I'll cut a sheet of quarter inch out and give it a test - As long as it doesnt warp from the heat, which I imagine it'll be getting very little heat it should work good.

I was thinking of buying a sheet of the protective acyrlic that Co2 Lasers cant go through... CNC out a honeycomb pattern, and theoretically it'd last forever. I havent found a good supplier in Canada that sells it for under a grand a sheet though...