-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wrong inks

- Thread starter heyskull

- Start date

Initially I would expect the wrong ink to cause a noticeable change in certain colours & possibly banding / poor quality in prints.

I would then be concerned if the wrong ink could clog the dampers and cap tops or even damage the print heads due to the different levels of solvent potentially in the ink.

I would be looking at print quality, if there is ink where there shouldn't be i.e. pooling out of the head during printing or overflowing on the cap tops.

Admittedly this is complete speculation as it's not something we have ever done and I don't know enough about the differences between Eco Sol max 2 and 3 to say what it could do & obviously any potential issue could have been there underlying anyway!

I would then be concerned if the wrong ink could clog the dampers and cap tops or even damage the print heads due to the different levels of solvent potentially in the ink.

I would be looking at print quality, if there is ink where there shouldn't be i.e. pooling out of the head during printing or overflowing on the cap tops.

Admittedly this is complete speculation as it's not something we have ever done and I don't know enough about the differences between Eco Sol max 2 and 3 to say what it could do & obviously any potential issue could have been there underlying anyway!

victor bogdanov

Active Member

What do you mean you think? Do the inks say Eco-Sol Max 2 or Eco-Sol Max 3 on them?I think my supplier has sent me the wrong ink and it is causing issues.

heyskull

New Member

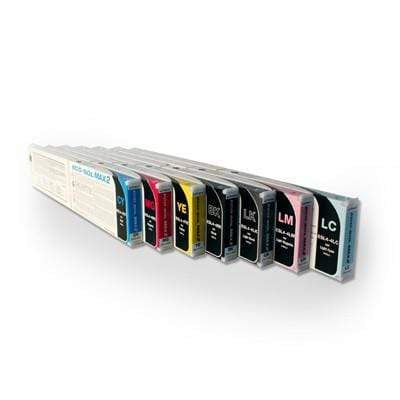

A while back I had a set of inks although marked externally as Max 3 when installed came up as "wrong ink type".

The supplier reckoned "the wrong chip had been installed" and sent others out to replace them.

My ink issues are as if some inks are not mixing as they should and leaving a mottled effect.

This mostly shows on anything with yellow in it.

SC

The supplier reckoned "the wrong chip had been installed" and sent others out to replace them.

My ink issues are as if some inks are not mixing as they should and leaving a mottled effect.

This mostly shows on anything with yellow in it.

SC

victor bogdanov

Active Member

Are these OEM inks or different brand inks?A while back I had a set of inks although marked externally as Max 3 when installed came up as "wrong ink type".

The supplier reckoned "the wrong chip had been installed" and sent others out to replace them.

My ink issues are as if some inks are not mixing as they should and leaving a mottled effect.

This mostly shows on anything with yellow in it.

SC

Solventinkjet

DIY Printer Fixing Guide

Eco Sol Max 3 inks are compatible with the following machines:

VersaSTUDIO BN-20 Series Printer/Cutters – CMYK + White and Metallic Ink**

VersaCAMM VS-i Printer/Cutters – CMYKLcLm + Light Black, White and Metallic Ink

SOLJET XR-640 Printer/Cutter – CMYKLcLm + Light Black, White and Metallic Ink

VersaEXPRESS RF-640 Printer – CYMK Ink

I don't know for sure but it looks like these are Roland's version of the faster drying inks that Mutoh switched to. If that's the case, mixing them could cause issues for sure. Clogging issues.

VersaSTUDIO BN-20 Series Printer/Cutters – CMYK + White and Metallic Ink**

VersaCAMM VS-i Printer/Cutters – CMYKLcLm + Light Black, White and Metallic Ink

SOLJET XR-640 Printer/Cutter – CMYKLcLm + Light Black, White and Metallic Ink

VersaEXPRESS RF-640 Printer – CYMK Ink

I don't know for sure but it looks like these are Roland's version of the faster drying inks that Mutoh switched to. If that's the case, mixing them could cause issues for sure. Clogging issues.

Last edited:

Solventinkjet

DIY Printer Fixing Guide

That does make it a bit different. 3rd party inks will often use the same ink and just change the chip for sure.These are Nazadar inks on a RF-640 4 colour machine.

My nozzle test is perfect and it has been checked by a Roland Tech and it is printing and aligned perfect.

SC

heyskull

New Member

Nazdar state they make a MAX 2 and MAX 3 ink.

On a further note.

I was on the US Roland Profile site and there only are profiles that are specifically for MAX 2 inks and do not show MAX 3.

The European site has the choice of MAX 2 & MAX 3.

Are MAX 3 inks not available in the US?

SC

On a further note.

I was on the US Roland Profile site and there only are profiles that are specifically for MAX 2 inks and do not show MAX 3.

The European site has the choice of MAX 2 & MAX 3.

Are MAX 3 inks not available in the US?

SC

victor bogdanov

Active Member

looks like itAre Roland MAX 3 inks available in the US?

SC

Roland EcoSol Max3 Ink

Roland Eco Sol MAX3 Ink ECO-SOL MAX 3 is the new generation of Roland DG's award-winning eco-solvent ink. The ink offers an overall high quality performance, with even faster drying times, bigger cartridges and a lower price per cc of ink. Of course, it also delivers the reliability, quality...

Roland Eco-Sol MAX 3 ESL5 Ink Set 7 Colours (500ml)

This set of 7 original Roland ESL5 inks includes one 500ml cartridge of each colour.

Novadon

LEF2-200

And another!

Eco-Sol Max 3 Digital Ink Cartridges | Roland DG | Nazdar SourceOne

Roland Eco-Sol Max 3 Digital Ink Cartridges has faster drying times, larger cartridges, a lower price and an overall better performance. Available now at N

sourceone.nazdar.com

Max3 was introduced in Europe, due to chemicals at the workplace regulations. They dry fairly quick. On the print medium, but also in the printer...

On introduction, they were also advertised to work on VP and SPi.

We had our troubles with DX4 machines and switched back to Max, or Max2.

The ink dries up in the black standard tubing of the DX4 captops. You needed to use captops with transparent tubing.(same as used for captops for DX7)

Overall, I liked the Max3 for it's clean yellow giving vibrant colors. But lately we had issues with this yellow clogging heads. We started switching back to Max2 for mor stable operation.

On introduction, they were also advertised to work on VP and SPi.

We had our troubles with DX4 machines and switched back to Max, or Max2.

The ink dries up in the black standard tubing of the DX4 captops. You needed to use captops with transparent tubing.(same as used for captops for DX7)

Overall, I liked the Max3 for it's clean yellow giving vibrant colors. But lately we had issues with this yellow clogging heads. We started switching back to Max2 for mor stable operation.

Might be time for thorough flush, and "inking up" with known good (correct ) inks

IF NOT...

Plan B would be something similar to my daily routine.

Wet the felt in captop(s) with proper cleaning solution at end of day, BE SURE the head is properly seated on captop TO AVOID INK DRYING INSIDE THE HEAD and run a cleaning cycle every morning

IF NOT...

Plan B would be something similar to my daily routine.

Wet the felt in captop(s) with proper cleaning solution at end of day, BE SURE the head is properly seated on captop TO AVOID INK DRYING INSIDE THE HEAD and run a cleaning cycle every morning