Hello everyone! I came here to my favorite place to see if anyone has had issues like this..

I always search around the forum before asking about an issue and I can see some people have had similar issues. It seems like the outsides of my print are being pulled into the center which causes a big perpendicular lump like a raised smile, ha. Eventually, I'm not smiling at the line of bubbles that appear. grrrrrr.

I've ran about 60 ft of material through the laminator without any problems and now I can't go 6 ft without scrapping the print.. I read people saying the pressures are uneven across the roll but it seems weird that it would just happen.

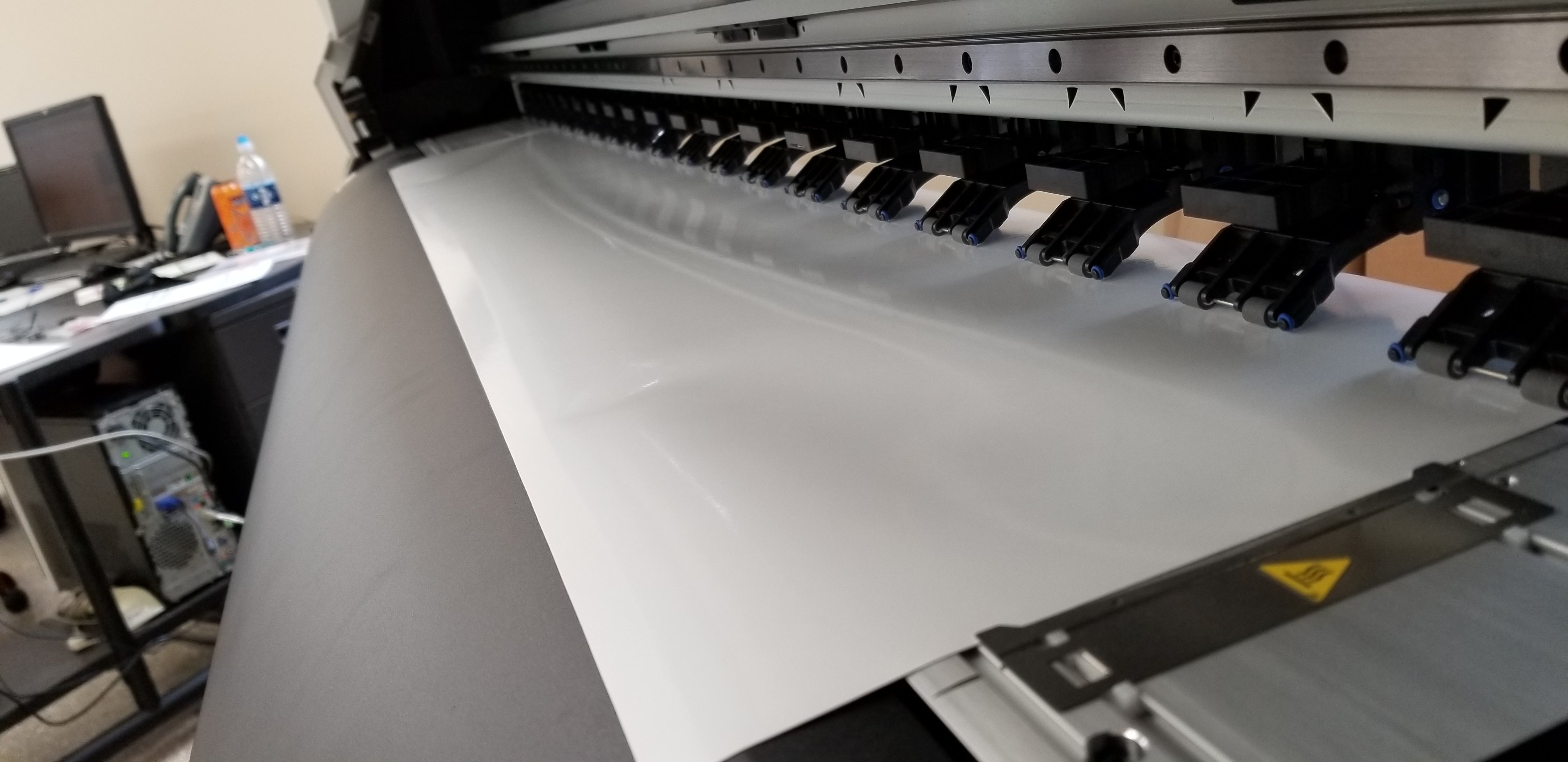

So the strange part... I walked over to my new Mimaki jv300 to reprint another piece and I noticed the EXACT same wrinkle on the material sitting on the platen! seems like too much of a coincidence to me.

I'm printing on 3m IJ180CV3, using the 3m profile in onyx.

The first pic is taken from exit of laminator, between the 2 sets of rollers. The second pic is the Vinyl coming off the printer.

Any ideas or suggestions?

I always search around the forum before asking about an issue and I can see some people have had similar issues. It seems like the outsides of my print are being pulled into the center which causes a big perpendicular lump like a raised smile, ha. Eventually, I'm not smiling at the line of bubbles that appear. grrrrrr.

I've ran about 60 ft of material through the laminator without any problems and now I can't go 6 ft without scrapping the print.. I read people saying the pressures are uneven across the roll but it seems weird that it would just happen.

So the strange part... I walked over to my new Mimaki jv300 to reprint another piece and I noticed the EXACT same wrinkle on the material sitting on the platen! seems like too much of a coincidence to me.

I'm printing on 3m IJ180CV3, using the 3m profile in onyx.

The first pic is taken from exit of laminator, between the 2 sets of rollers. The second pic is the Vinyl coming off the printer.

Any ideas or suggestions?

Last edited: