Hello!

I've been tasked with adding LED's to some laser cut acrylic letters that we plan on installing on the side of our buildling.

I wasn't sure what style would work best, so I ordered 5-10 different kinds for testing.

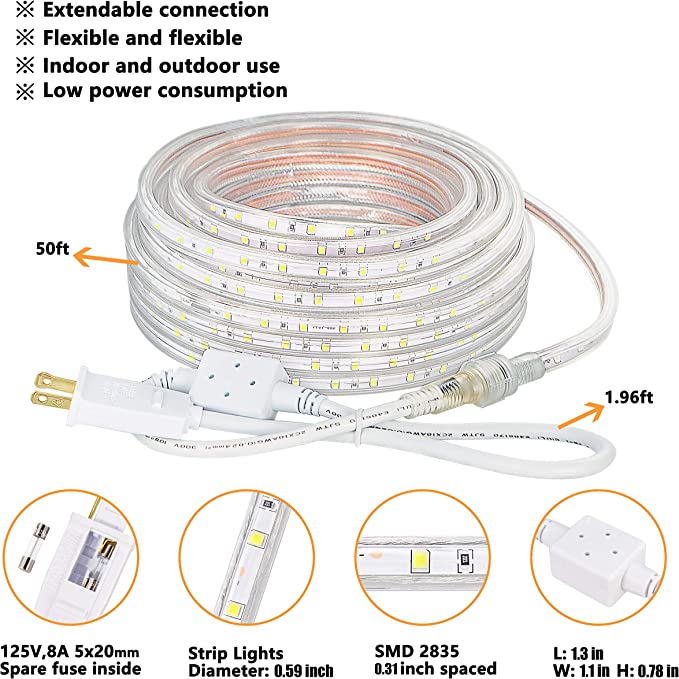

The two main categories I found were high voltage (not sure if AC or DC but they measured roughly 110v with the DMM on both modes) where the LED's and silver wire are completely enclosed in a stiff, thick rubber tube:

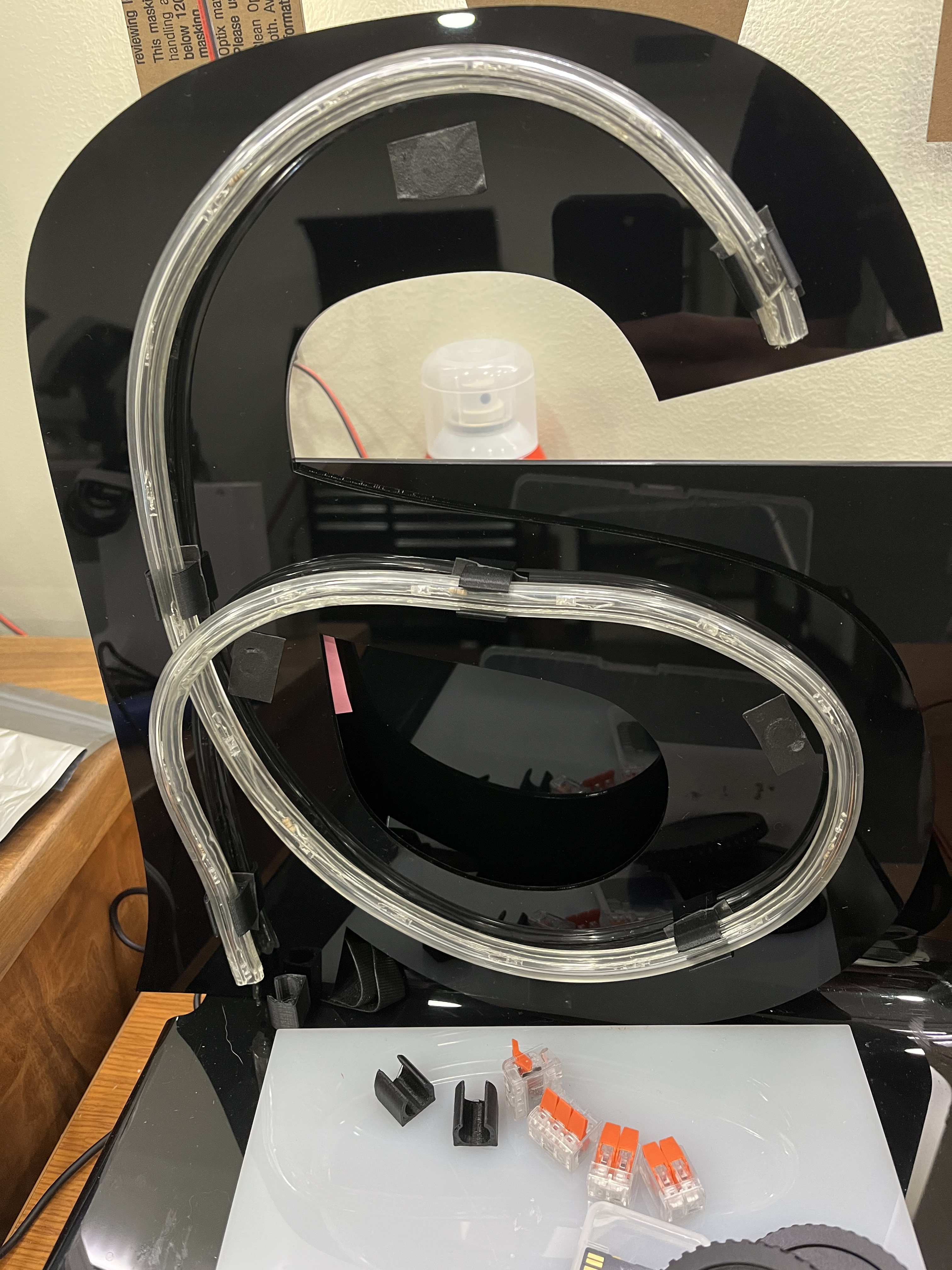

I printed some fingers to hold these tubes onto the acrylic and it -kind of- worked.

Obstacles with this style of LED:

-The cut segments are restrictive: minimum segment length they can be cut to is 1m without having to do extra wiring

-Cutting the rubber casing is not easy; if you wanted say 30 1m segments for 30 signage characters, there's a huge labor factor exposing the leads from inside the rubber encasement

-Not easily dimmable, though this isn't really a drawback for most who will run their lights at max brightness

Advantages of this style of LED:

-Most robust housing/enclosure I've come across. As long as you properly seal the ends, these would very likely last the longest.

Style 2: Low voltage

These are your standard flat ribbon/pcb typically rated for 12 or 24v DC except they have a thin rubberized coating covering the LED's and top side of the ribbon strip.

Advantages:

-Much more flexibility in cutting small lengths/segments

-Far brighter (at least the ones I ordered)

-12 and 24V DC are easily dimmable

Disadvantages:

-Adhesive is really not great, even when applying to a perfectly clean and oil free surface

-Waterproofing really doesn't seem like it's going to last

Style 3:

Continuously illuminated soft glow, I have no idea what these go by besides "silicone tube"

I'll add photos to the next post since I'm limited to 5.

I've been tasked with adding LED's to some laser cut acrylic letters that we plan on installing on the side of our buildling.

I wasn't sure what style would work best, so I ordered 5-10 different kinds for testing.

The two main categories I found were high voltage (not sure if AC or DC but they measured roughly 110v with the DMM on both modes) where the LED's and silver wire are completely enclosed in a stiff, thick rubber tube:

I printed some fingers to hold these tubes onto the acrylic and it -kind of- worked.

Obstacles with this style of LED:

-The cut segments are restrictive: minimum segment length they can be cut to is 1m without having to do extra wiring

-Cutting the rubber casing is not easy; if you wanted say 30 1m segments for 30 signage characters, there's a huge labor factor exposing the leads from inside the rubber encasement

-Not easily dimmable, though this isn't really a drawback for most who will run their lights at max brightness

Advantages of this style of LED:

-Most robust housing/enclosure I've come across. As long as you properly seal the ends, these would very likely last the longest.

Style 2: Low voltage

These are your standard flat ribbon/pcb typically rated for 12 or 24v DC except they have a thin rubberized coating covering the LED's and top side of the ribbon strip.

Advantages:

-Much more flexibility in cutting small lengths/segments

-Far brighter (at least the ones I ordered)

-12 and 24V DC are easily dimmable

Disadvantages:

-Adhesive is really not great, even when applying to a perfectly clean and oil free surface

-Waterproofing really doesn't seem like it's going to last

Style 3:

Continuously illuminated soft glow, I have no idea what these go by besides "silicone tube"

I'll add photos to the next post since I'm limited to 5.