jtiii

I paid good money for you to read this!

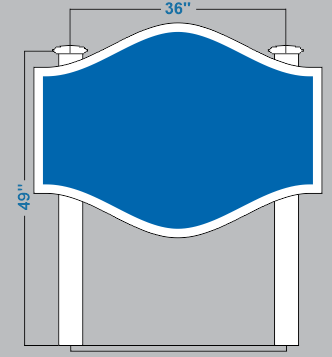

Hey all, I dug around a bit but I'm not sure how to approach this. I've got a 3'x4' 6mm alupanel sign going on a couple of fiberon 4x4 sleeves.

I've done lots of signs more or less like this, but they've always been roadside so a few discrete fasteners were no big deal.

This sign though is going right next to the sidewalk at the entrance to the building so I want to do it without fasteners.

Compounding the issue is that it's for the county and they insist on installing themselves. How should I do this?

I've done lots of signs more or less like this, but they've always been roadside so a few discrete fasteners were no big deal.

This sign though is going right next to the sidewalk at the entrance to the building so I want to do it without fasteners.

Compounding the issue is that it's for the county and they insist on installing themselves. How should I do this?