frojasferrari

New Member

Hi there, long time no post....

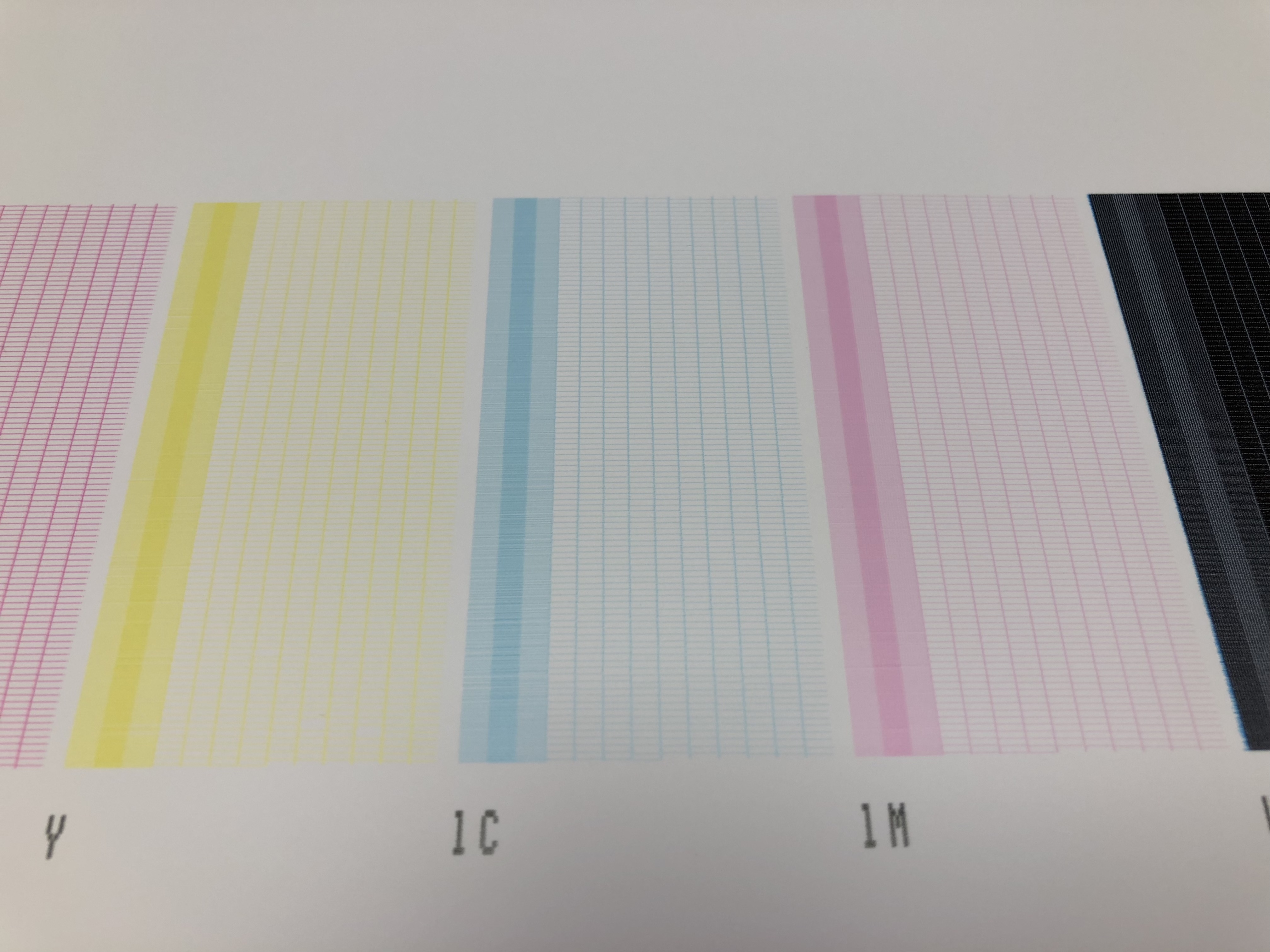

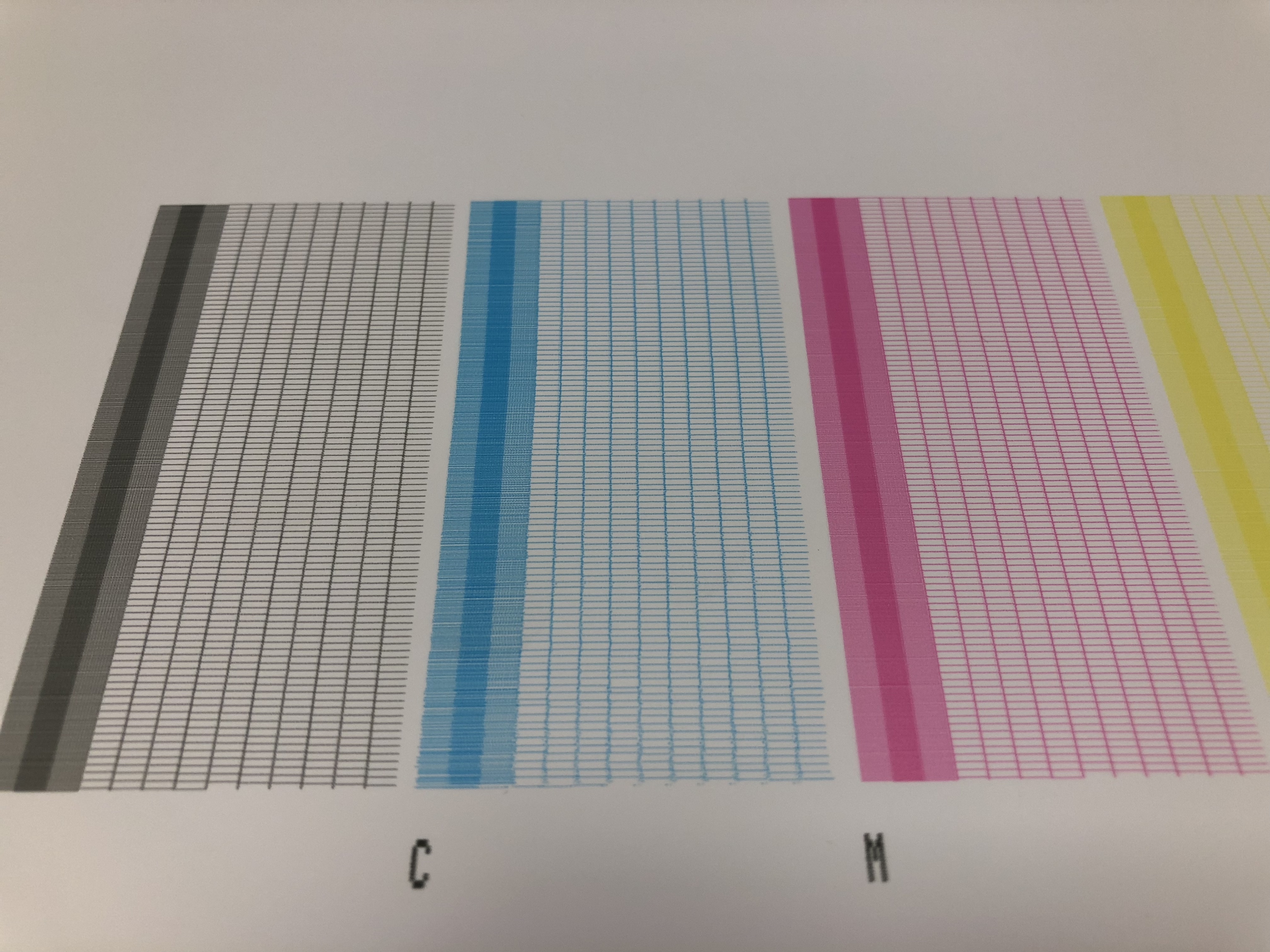

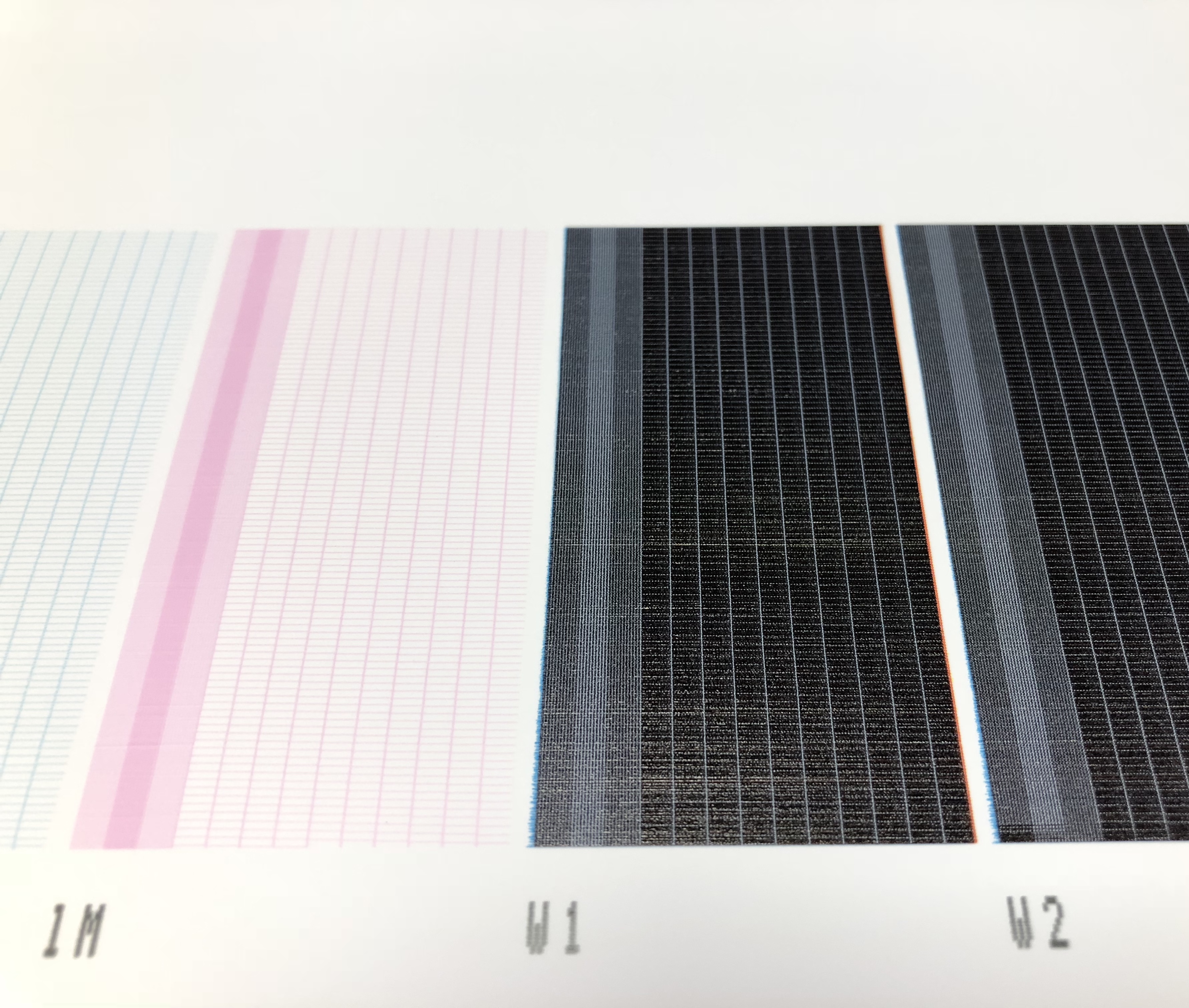

We are having a problem with our 2 years old Anapurna H2500i. The cyan its banding. When you print the PRIME , the machine prints the typical grid where you can see all the nozzles firing and on the right side of this grid it print solid colors, in the solid colors you can see white lines, as if the nozzles are deflected, but on the grid pattern you can se everything alright, except for my cyan that is "shaky" on top and bottom of the grid. The technicians of the brand (Anapurna... so do the math) have not been able to even DIAGNOSE whats wrong, they are going for the easy exit, new printhead, we don't have problems on changing the printheads, but we want to know WHY this happened, so the new printheads don't have the exact same problem in a year (the cyan started showing this on January). Heres a video:

We are having a problem with our 2 years old Anapurna H2500i. The cyan its banding. When you print the PRIME , the machine prints the typical grid where you can see all the nozzles firing and on the right side of this grid it print solid colors, in the solid colors you can see white lines, as if the nozzles are deflected, but on the grid pattern you can se everything alright, except for my cyan that is "shaky" on top and bottom of the grid. The technicians of the brand (Anapurna... so do the math) have not been able to even DIAGNOSE whats wrong, they are going for the easy exit, new printhead, we don't have problems on changing the printheads, but we want to know WHY this happened, so the new printheads don't have the exact same problem in a year (the cyan started showing this on January). Heres a video: