Biker Scout

New Member

OK, guys... here it is, the Banner Jet (T-Jet) install and all the subsequent information associated with it, along with my UV Ink Conversion.

I figured, I'd better start logging this info in now before it becomes too overwhelming and too much information to even bother posting all at once. So, I'll be trickling this info in as I go along. My UV ink is being ordered today, as I write this. So while this is for posterity and kind of a journal of my dealings with a Chinese printer.

First let's start off with where I ordered it from: TEC Industry & Trade. Their website is kinda confusing and too many printer options to make an informed decision just by looking at the printers. You really gotta know exactly what you want when you contact them.

Their website: tecprinter.com.cn or signequ.com

My contact: Yuki (yukixu@tecprinter.com.cn)

What I was looking for: At least a 64" (1.6m) printer for under $5k, with a legit Epson DX7 printhead

My search of course started at Alibaba.com, I found a couple of contenders but I kept coming back to the T-Jet. Mainly because I recall seeing TEC at the sign show. I looked at their credentials, and they've been in business awhile, 2.5 million in revenue per year, their operations have been independently checked and verified that they are in fact the OEM manufacturer and do in fact offer what they are claiming to sell on their website. Plus, if this transaction went well, they do happen to have a UV Flatbed that is really nice, and was mentioned that they are the OEM of that printer for a couple of other larger manufacturers.

Things I liked about TEC: HiWin Linear Guide Rails, Price, DX7 Head, RIP Upgrade, Wave-Form Printing, Media Take-Up, Color (I originally wanted green, but more on that later) 24/7 skype tech support, their house brand ink only $20 per liter (but I didn't use that as a consideration, because of my intent to convert to UV inks anyway) simple machine design (no proprietary components that could fail that are hard to get and replace) all replacement parts are shipped next day via DHL if something should need replacing (then you ship back your part, so minimal downtime)

I saw a lengthly video of a Brazilian guy tour their factory and sign show in China. He was very impressed that he became an importer for South America. Which is why I think they are sometimes called BannerJet (T-Jet is the official designation. Makes sense because the company does start with a "T" | TEC Printer) Banner Jet might have been his branding idea, plus the bright color schemes. It seems that before that guy got involved, they were all gray printers. But that's not really important.

John Thomson on our board, in Scotland has one of these, and he loves it! Aside from his early struggles to obtain a decent color profile. Apparently that's sorted out now. He also has a short YouTube video clip of the thing running and shows some really nice gradients.

Of course I needed to see some print samples first. I gave them my UPS account number and 4 days later I had some small prints in hand.

Looked good enough to me. (Although the red one is from the ink company, but also on a DX7 head. I wanted to check color fidelity and saturation before I decided on an ink manufacturer)

What I ended up getting: T-Jet 1671 (I'm assuming it means 1.6m wide, DX7 head - 1 of them) $3300 FOB

I had them throw in an electric cold mount laminator (basic mounter really) for $500, only added $84 to the freight cost. (I wanted this machine for the 2 rollers... more on that project later)

Some of their confusion on their website leads you to believe that you can pick your color. From Green, Orange or Gray. Well, apparently the Gray is the older model. Some internal improvement have been made since then. And the Green is only available in 1.8m, while the Orange is only a 1.6 model.

I almost went for the 74" model. It was only $400 more. But here's why I didn't... common material availability. There are only a handful of items that even come in 74" wide, and I don't do anything in textiles. And who really orders a 6' wide banner? The only real difference in our industry comes in at 102" and above. Then you can get dirt cheap materials, be able to run an 8' banner short ways. But that's not what this printer experiment is about really. 64" is the widest industry standard of the medium to small wide format printers. This allows for full one piece hood wraps without seams, if that's your market. And 54" is just annoyingly wider than 48" which is the industry standard for a board. So you always end up with waste that you pay for. And the couple of 48" wide printers on the market don't really quite print full bleed. The largest board we can readily buy is 5x10. The 64" (1.6m) covers that product segment.

I considered the dual head option, but that bumped the price considerably to $5200. Was I really gonna need the extra speed a second head provided? Maybe, but if all goes well, I can buy a faster printer down the road with cash. And I didn't want to chance it with my first Chinese printer running 2 heads I was not familiar with. I'm coming from a DX5 head in both my Mutoh and Rolands. So I'm pretty confident in those, and didn't want to have to end up down the hellish road I went down the DX5 when I did have a print head problem. So, let's keep it simple and more affordable. Besides, my slush fund for this printer project was $6000.

I used Western Union, went fine. But was weird having to send to some guy in China instead of their bank or corporate name. (Our bank, Chase, had suspended wire transfers to China at that time. Or at least their bank in particular and was not expected to be back up until April of 2014. We needed to get this order off before Dec 31, to get their promotional pricing, so waiting until April wasn't going to happen)

Our only headache was not having an importer in place right after we sent the money. There was some delay between me and my partner because he had to go back to Ohio to deal with his father's death, and this was also during the blizzard from hell. Anyway, we found this guy who imports stuff all the time for one of my other clients. To simplify the process, he has us fill out a POA for import, and he handled the rest. We paid the local forwarder, which included a bunch of nonsense duties, fees and customs BS. Which added about $800 - $900 to our surprise. Anyway, our importer guy later sent us a bill for only $100. Which we were more than happy to pay considering all he had done for us.

Printer arrived, and it was one heavy mo-fo. Better have a forklift or some other creative/safe way to get it off the truck. We were fortunate that we have a dock, but no forklift. Some freight companies offer lift gate service, but honestly that crate was so long I don't see how they could have gotten it on the lift gate in the first place. Have a forklift, or lots of dudes to lift one end and a couple of dollies. I think the crate was 1500 lbs. Plus our laminator thing was on top of that crate too.

[video=youtube;e_1PsHwMAWs]https://www.youtube.com/watch?v=e_1PsHwMAWs&feature=youtu.be[/video]

One interesting thing I found when taking off the panels to inspect for my UV conversion...

They have LED lights under the top panel. That's a nice touch.

As of this post I still need to get a power cord. The one the sent me was like Australian or European. I found a 14 foot 220v NEMA style twist plug on ebay for $29. I just ordered that this evening. This printer will run 110v, if you notice at the end of the video, there are two boxes. One is a standard (easily replaceable) power supply and the other is a transformer that has a little switch on the side to change voltages. I happen to have a 220v outlet where this thing is going to go, and it will run a bit more efficient anyway.

Since I'm waiting to even plug this thing in, and install the print head and ink... I decided to get started on the UV light conversion.

This set-up is going in place of my fan bar, which I won't need. However I may end up using the onboard power for the fan to light this up and steal one of the rocker switches. Now this UV LED is nothing special, it's just an eBay thing, $20 I'm guessing. Came with power supply. I stuck them to an aluminum extrusion I had. (Also acts as heat sink) These are supposedly 635mn wavelength. Which is what my ink cure at. However, only 12 watts. So I don't expect this bar to cure the ink all by itself. This is my secondary cure unit. The first UV light is 100W and mounts right on the print head carriage with it's own heat sink and fan. That will be installed with a magnetic reed switch, so when the head is parked or over the capping station the light turns off.

Now this thing is very bright, and gives off an extraordinary amount of heat. Which is why high end LEDs have heat sinks. I picked this up from the actual manufacturer for $157, delivered. I've seen them re-sold for over $800 locally. Same light, same specs. It also came with matched driver. It's range is 395nm to 400nm, which is also the range I need according to the ink manufacturer.

I am in the process of designing a bracket that will hold this next to the print head carriage.

And that is where things stand as of now. I'll keep updating as things progress.

I figured, I'd better start logging this info in now before it becomes too overwhelming and too much information to even bother posting all at once. So, I'll be trickling this info in as I go along. My UV ink is being ordered today, as I write this. So while this is for posterity and kind of a journal of my dealings with a Chinese printer.

First let's start off with where I ordered it from: TEC Industry & Trade. Their website is kinda confusing and too many printer options to make an informed decision just by looking at the printers. You really gotta know exactly what you want when you contact them.

Their website: tecprinter.com.cn or signequ.com

My contact: Yuki (yukixu@tecprinter.com.cn)

What I was looking for: At least a 64" (1.6m) printer for under $5k, with a legit Epson DX7 printhead

My search of course started at Alibaba.com, I found a couple of contenders but I kept coming back to the T-Jet. Mainly because I recall seeing TEC at the sign show. I looked at their credentials, and they've been in business awhile, 2.5 million in revenue per year, their operations have been independently checked and verified that they are in fact the OEM manufacturer and do in fact offer what they are claiming to sell on their website. Plus, if this transaction went well, they do happen to have a UV Flatbed that is really nice, and was mentioned that they are the OEM of that printer for a couple of other larger manufacturers.

Things I liked about TEC: HiWin Linear Guide Rails, Price, DX7 Head, RIP Upgrade, Wave-Form Printing, Media Take-Up, Color (I originally wanted green, but more on that later) 24/7 skype tech support, their house brand ink only $20 per liter (but I didn't use that as a consideration, because of my intent to convert to UV inks anyway) simple machine design (no proprietary components that could fail that are hard to get and replace) all replacement parts are shipped next day via DHL if something should need replacing (then you ship back your part, so minimal downtime)

I saw a lengthly video of a Brazilian guy tour their factory and sign show in China. He was very impressed that he became an importer for South America. Which is why I think they are sometimes called BannerJet (T-Jet is the official designation. Makes sense because the company does start with a "T" | TEC Printer) Banner Jet might have been his branding idea, plus the bright color schemes. It seems that before that guy got involved, they were all gray printers. But that's not really important.

John Thomson on our board, in Scotland has one of these, and he loves it! Aside from his early struggles to obtain a decent color profile. Apparently that's sorted out now. He also has a short YouTube video clip of the thing running and shows some really nice gradients.

Of course I needed to see some print samples first. I gave them my UPS account number and 4 days later I had some small prints in hand.

Looked good enough to me. (Although the red one is from the ink company, but also on a DX7 head. I wanted to check color fidelity and saturation before I decided on an ink manufacturer)

What I ended up getting: T-Jet 1671 (I'm assuming it means 1.6m wide, DX7 head - 1 of them) $3300 FOB

I had them throw in an electric cold mount laminator (basic mounter really) for $500, only added $84 to the freight cost. (I wanted this machine for the 2 rollers... more on that project later)

Some of their confusion on their website leads you to believe that you can pick your color. From Green, Orange or Gray. Well, apparently the Gray is the older model. Some internal improvement have been made since then. And the Green is only available in 1.8m, while the Orange is only a 1.6 model.

I almost went for the 74" model. It was only $400 more. But here's why I didn't... common material availability. There are only a handful of items that even come in 74" wide, and I don't do anything in textiles. And who really orders a 6' wide banner? The only real difference in our industry comes in at 102" and above. Then you can get dirt cheap materials, be able to run an 8' banner short ways. But that's not what this printer experiment is about really. 64" is the widest industry standard of the medium to small wide format printers. This allows for full one piece hood wraps without seams, if that's your market. And 54" is just annoyingly wider than 48" which is the industry standard for a board. So you always end up with waste that you pay for. And the couple of 48" wide printers on the market don't really quite print full bleed. The largest board we can readily buy is 5x10. The 64" (1.6m) covers that product segment.

I considered the dual head option, but that bumped the price considerably to $5200. Was I really gonna need the extra speed a second head provided? Maybe, but if all goes well, I can buy a faster printer down the road with cash. And I didn't want to chance it with my first Chinese printer running 2 heads I was not familiar with. I'm coming from a DX5 head in both my Mutoh and Rolands. So I'm pretty confident in those, and didn't want to have to end up down the hellish road I went down the DX5 when I did have a print head problem. So, let's keep it simple and more affordable. Besides, my slush fund for this printer project was $6000.

I used Western Union, went fine. But was weird having to send to some guy in China instead of their bank or corporate name. (Our bank, Chase, had suspended wire transfers to China at that time. Or at least their bank in particular and was not expected to be back up until April of 2014. We needed to get this order off before Dec 31, to get their promotional pricing, so waiting until April wasn't going to happen)

Our only headache was not having an importer in place right after we sent the money. There was some delay between me and my partner because he had to go back to Ohio to deal with his father's death, and this was also during the blizzard from hell. Anyway, we found this guy who imports stuff all the time for one of my other clients. To simplify the process, he has us fill out a POA for import, and he handled the rest. We paid the local forwarder, which included a bunch of nonsense duties, fees and customs BS. Which added about $800 - $900 to our surprise. Anyway, our importer guy later sent us a bill for only $100. Which we were more than happy to pay considering all he had done for us.

Printer arrived, and it was one heavy mo-fo. Better have a forklift or some other creative/safe way to get it off the truck. We were fortunate that we have a dock, but no forklift. Some freight companies offer lift gate service, but honestly that crate was so long I don't see how they could have gotten it on the lift gate in the first place. Have a forklift, or lots of dudes to lift one end and a couple of dollies. I think the crate was 1500 lbs. Plus our laminator thing was on top of that crate too.

[video=youtube;e_1PsHwMAWs]https://www.youtube.com/watch?v=e_1PsHwMAWs&feature=youtu.be[/video]

One interesting thing I found when taking off the panels to inspect for my UV conversion...

They have LED lights under the top panel. That's a nice touch.

As of this post I still need to get a power cord. The one the sent me was like Australian or European. I found a 14 foot 220v NEMA style twist plug on ebay for $29. I just ordered that this evening. This printer will run 110v, if you notice at the end of the video, there are two boxes. One is a standard (easily replaceable) power supply and the other is a transformer that has a little switch on the side to change voltages. I happen to have a 220v outlet where this thing is going to go, and it will run a bit more efficient anyway.

Since I'm waiting to even plug this thing in, and install the print head and ink... I decided to get started on the UV light conversion.

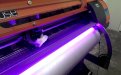

This set-up is going in place of my fan bar, which I won't need. However I may end up using the onboard power for the fan to light this up and steal one of the rocker switches. Now this UV LED is nothing special, it's just an eBay thing, $20 I'm guessing. Came with power supply. I stuck them to an aluminum extrusion I had. (Also acts as heat sink) These are supposedly 635mn wavelength. Which is what my ink cure at. However, only 12 watts. So I don't expect this bar to cure the ink all by itself. This is my secondary cure unit. The first UV light is 100W and mounts right on the print head carriage with it's own heat sink and fan. That will be installed with a magnetic reed switch, so when the head is parked or over the capping station the light turns off.

Now this thing is very bright, and gives off an extraordinary amount of heat. Which is why high end LEDs have heat sinks. I picked this up from the actual manufacturer for $157, delivered. I've seen them re-sold for over $800 locally. Same light, same specs. It also came with matched driver. It's range is 395nm to 400nm, which is also the range I need according to the ink manufacturer.

I am in the process of designing a bracket that will hold this next to the print head carriage.

And that is where things stand as of now. I'll keep updating as things progress.