sean@indyprint

New Member

hey folks!

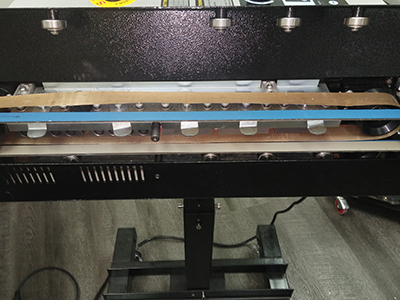

we've got a Royal (pain in the ass) sovereign RBW-1500s banner wielder that has been giving us nothing but problems

1-the copper and blue pulleys aren't staying even with each other..the top blue and copper pulleys go off track and don't line up correctly

2-the banner material will get eaten up by the heat of the roller but only in some spots not through the entire weld

3- (MOST RECENTLY) the banner will get scrunched up at the beginning of the weld run and start bunching up the whole banner with ripples that have to be straightened out by hand (while trying to weld the banner at the same time)

we've got a Royal (pain in the ass) sovereign RBW-1500s banner wielder that has been giving us nothing but problems

1-the copper and blue pulleys aren't staying even with each other..the top blue and copper pulleys go off track and don't line up correctly

2-the banner material will get eaten up by the heat of the roller but only in some spots not through the entire weld

3- (MOST RECENTLY) the banner will get scrunched up at the beginning of the weld run and start bunching up the whole banner with ripples that have to be straightened out by hand (while trying to weld the banner at the same time)