Roto

New Member

Hi folks,

My question is when using a down cutter how do I get the swarf to adhere to the part of the cut I am iscarding.

E.g. if I am cutting on the outside of an A I want the swarf to cling to the centre of the A and to the outside piece I am going to discard.

Then when cutting a letter through a piece and I am throwing away the A How do I get the swarf to cling to the piece I am discarding leaving me with a clean centre A and a clean intercut.

I hope I am making myself clear.

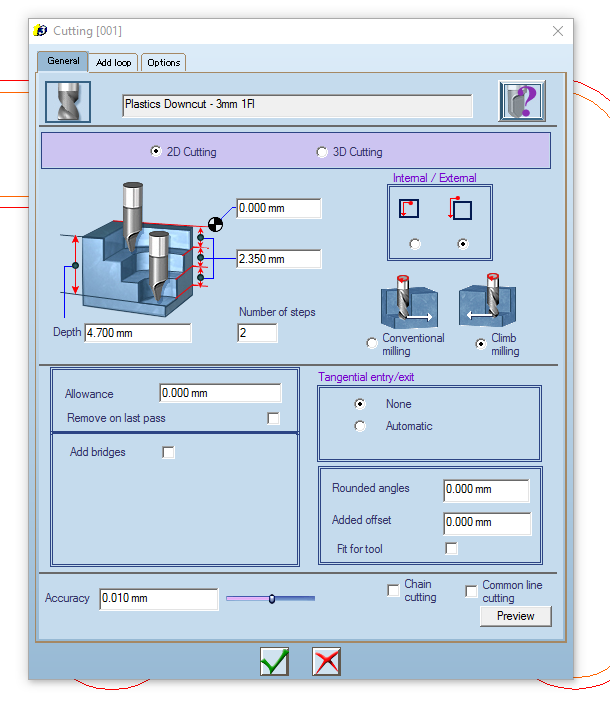

I will attach a screen cap of my router settings.

TIA

My question is when using a down cutter how do I get the swarf to adhere to the part of the cut I am iscarding.

E.g. if I am cutting on the outside of an A I want the swarf to cling to the centre of the A and to the outside piece I am going to discard.

Then when cutting a letter through a piece and I am throwing away the A How do I get the swarf to cling to the piece I am discarding leaving me with a clean centre A and a clean intercut.

I hope I am making myself clear.

I will attach a screen cap of my router settings.

TIA