So, there is probably one printer for every 10,000 folks in my town. Of those 10k folks, 50 are going to purchase a

sign at some point this year. The one printer... it may break this year, it may not.

Just saying, two totally different markets.

See, I don't have days like that, I have 2am wake up moments of 'aww what the f*ck am I doing' that run in a feedback loop until I get out of bed and get some coffee. Exciting is one way to describe it.

Man, my 6x12 router cuts my multi layered ada stuff, it kicks the crap out of the old engraver we have. Haven't gotten it to do braille, mostly because of the lack of a 'nose' on the spindle to keep any variation from going too deep, but I am certain it could work across a small area.

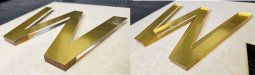

Looking at the picture here, slap some vinyl on the back and it'll look 90% like brushed brass.