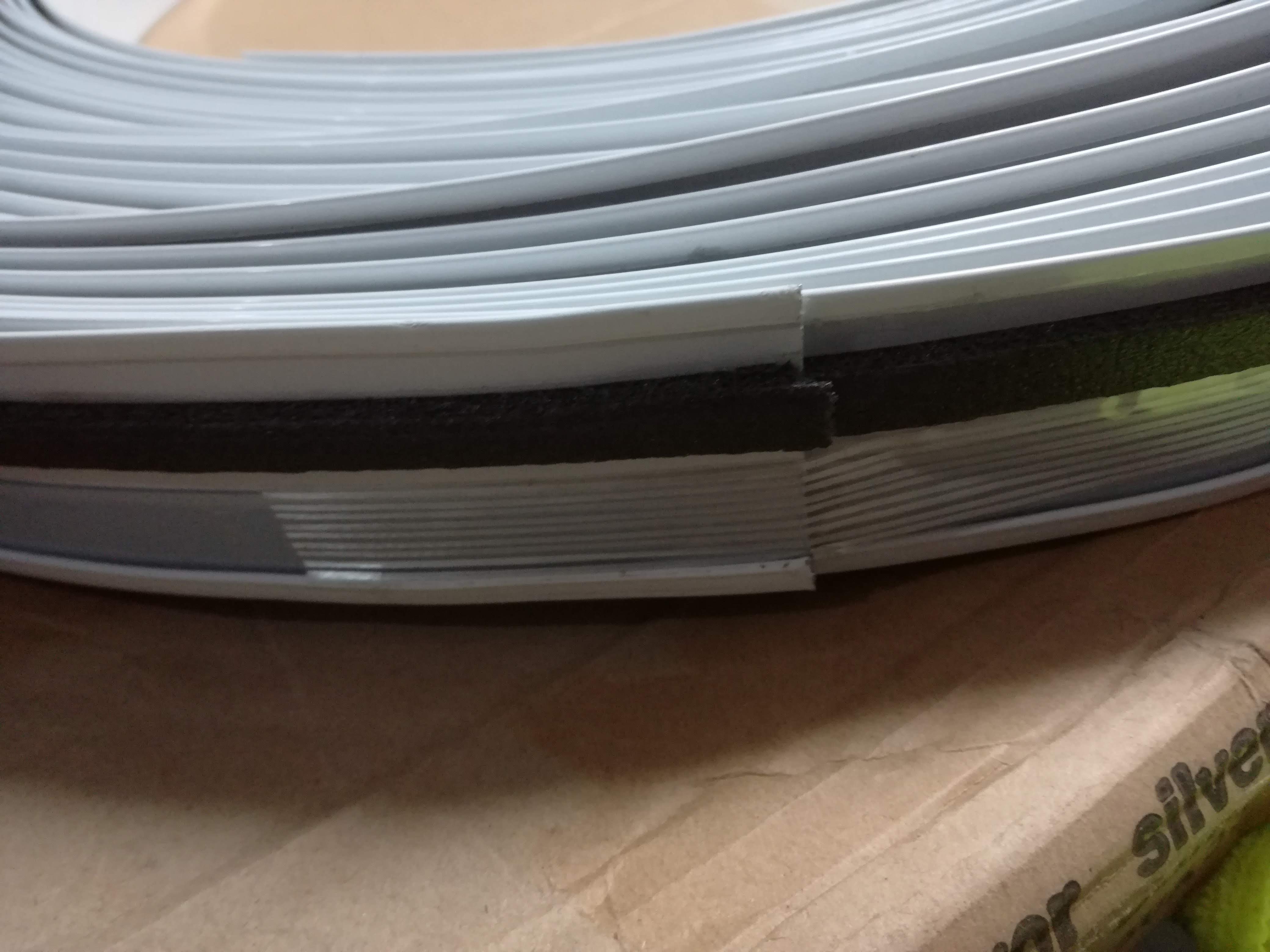

Hi, I ordered what I thought was aluminium roll for channel letters, my Spanish supplier sent this, does anyone have experience with this? I think the PVC goes below the foam which would be at the bottom. Also can anyone recommend a tool to bend the aluminium to the form of the letters? links appreciated.

-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

channel letters material and tools

- Thread starter bingo

- Start date

some of us have no other optionIt scares the crap out of me that people are trying to learn how to build and install channel letters from a forum.

Do you have a recommendation fort a "4' finger brake" I did a quick search and most seem too big for my needs.I it was my intention initially to continue to have the faces and backs cut by a third party, but a router has been on the shopping list for a long time. Thanks for the tips!

Robbie Moore

New Member

Do you have a recommendation fort a "4' finger brake" I did a quick search and most seem too big for my needs.I it was my intention initially to continue to have the faces and backs cut by a third party, but a router has been on the shopping list for a long time. Thanks for the tips!

Until you have all the components I wouldn’t start manufacturing in house. You need a CNC router, accubend machine or another brand to produce the returns, hundreds of magnets, set of knickers and some knowledge on LEDs and wiring.

kcollinsdesign

Old member

You are probably doing 3 or more sets of channel letters/day to be able to make them cheaper than they are available from a wholesaler. By now you should know everything there is to know about making these. I don't understand the post.