-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CNC height detector

- Thread starter basem2b2

- Start date

letterman7

New Member

Sounds to me that your cutting bed isn't flat. If it's 3mm acrylic, it's 3mm acrylic. Those tolerances usually don't vary from a manufacturer. But to answer your question, it all depends on what machine and software you're running. Some programs have a built-in Z zero setting, but it won't self adjust while it's running. I can't think of any that would since the programming would need to adjust on the fly.

It kind of depends on what you are doing. If you are just cutting out shapes, you would zero the z-axis to the top of the bed (i.e. the underside of the acrylic) all cnc software should allow you to do this. Since the zero point is now set to the machines table, any small fluctuations in the acrylic thickness shouldn't matter.

thanks for the response

thanks for the response

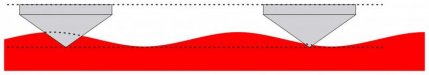

cutting bed is flat but the sheet it self is the problem, the thing is, I am doing some V carving 150 degree

so when the thickness is not all the same, that gets me uneven and disturbed shapes

that's why I am looking for some techniques to get the machine go along with the sheet thickness

View attachment 92782

thanks for the response

cutting bed is flat but the sheet it self is the problem, the thing is, I am doing some V carving 150 degree

so when the thickness is not all the same, that gets me uneven and disturbed shapes

that's why I am looking for some techniques to get the machine go along with the sheet thickness

View attachment 92782

Attachments

letterman7

New Member

Hmm.. v-carving in 3mm. That creates problems all it's own. Unless the acrylic is textured in some way there still shouldn't be any issue. It's possible that the heat from the bit is warping the acrylic on deeper plunges, and that may be affecting the immediate area, but other than that I have no suggestions. Flat sheet is flat sheet - if yours isn't to spec and flat, why are you trying to rout it? Send it back or try another sheet. There are no programs or techniques that will allow the bit to follow the uneven contours of a sheet. You either need to check your sheets at the beginning with a straightedge or deal with the problems of trying to rout material so thin.

Hmm.. v-carving in 3mm. That creates problems all it's own. Unless the acrylic is textured in some way there still shouldn't be any issue. It's possible that the heat from the bit is warping the acrylic on deeper plunges, and that may be affecting the immediate area, but other than that I have no suggestions. Flat sheet is flat sheet - if yours isn't to spec and flat, why are you trying to rout it? Send it back or try another sheet. There are no programs or techniques that will allow the bit to follow the uneven contours of a sheet. You either need to check your sheets at the beginning with a straightedge or deal with the problems of trying to rout material so thin.

true the sheet it self is the problem, the variation in thickness could reach 0.5 mm of 3 mm, and that's a lot so I probably will look for new supplier thanks for you help

SebastienL

New Member

That's some mighty cheap *** acrylic you got there if the variation in thickness varies up to .5mm. That's .019". That's way outside most manufacturer tolerances. Personally, I'd return that crap and get decent acrylic.

My guess is your table is not flat or the material is not laying flat on the table.

My guess is your table is not flat or the material is not laying flat on the table.

CanuckSigns

Active Member

We've had issues with 6mm p95 acrylic not being the same thickness from one end to the other, it wasn't a big deal for us, but annoying none the less

That's some mighty cheap *** acrylic you got there if the variation in thickness varies up to .5mm. That's .019". That's way outside most manufacturer tolerances. Personally, I'd return that crap and get decent acrylic.

My guess is your table is not flat or the material is not laying flat on the table.

going to take your advise and throw the dealer and the acrylic.

about the table, I had installed an MDF wood sheet over my machine table and then used a 20 mm flat drill bit to level the entire sheet of any disturbing in thickness, that's why I'am surprised of the result of the work that came not like expected.