Gnome Beard

Guest

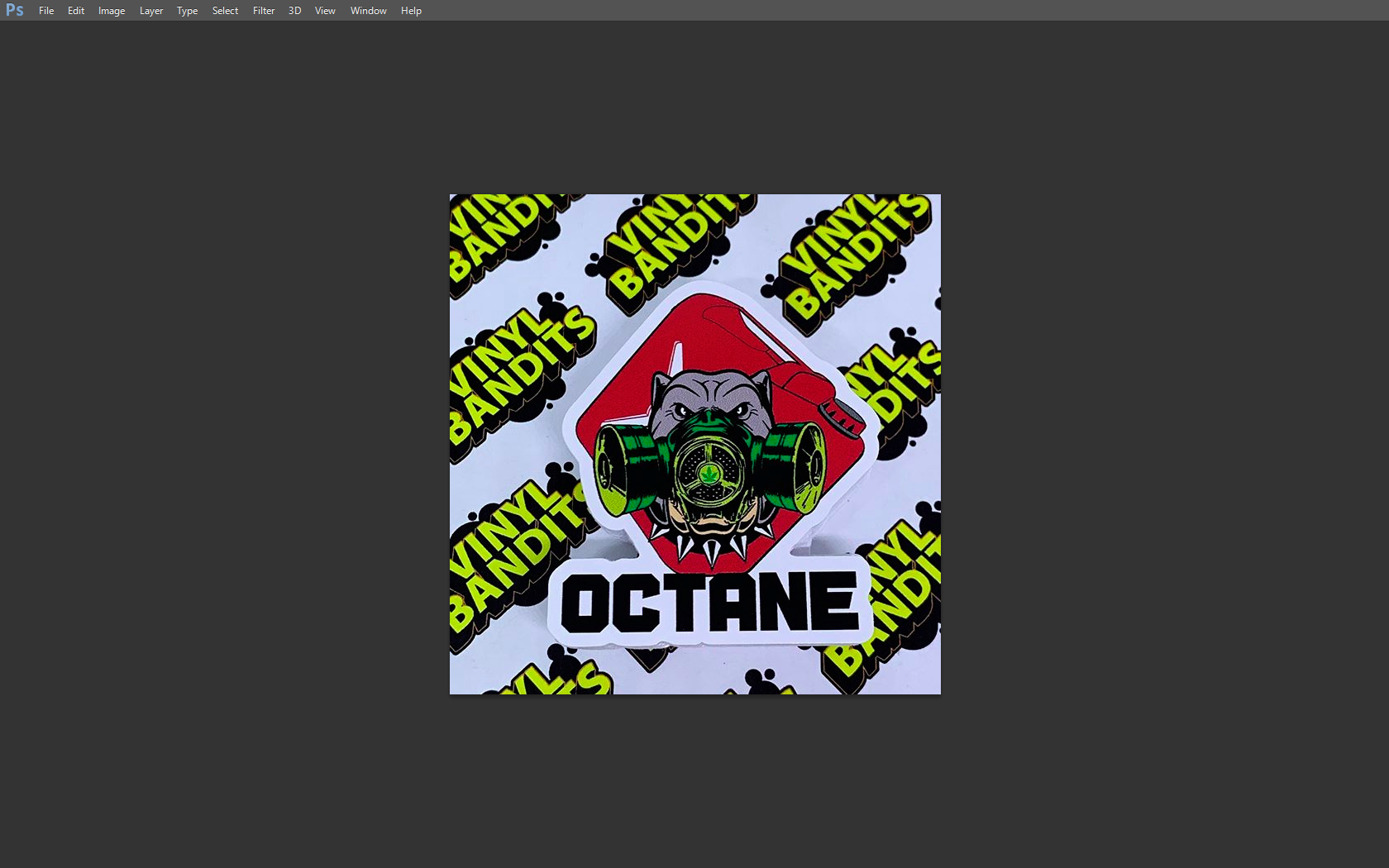

I see all these companies coming out with die-cut stickers and decals, like sticker app, Vinyl Bandits, Rockin' Stickers, etc.

What material are they using? Maybe something that doesn't have curl. The media I have tends to curl on the edges after a while.

I have an HP Latex 360 and a Canon iPF8400s.

For cutting, I have a Graphtec FC8600

Also, wouldn't I wear out my blade really quick using a Graphtec?

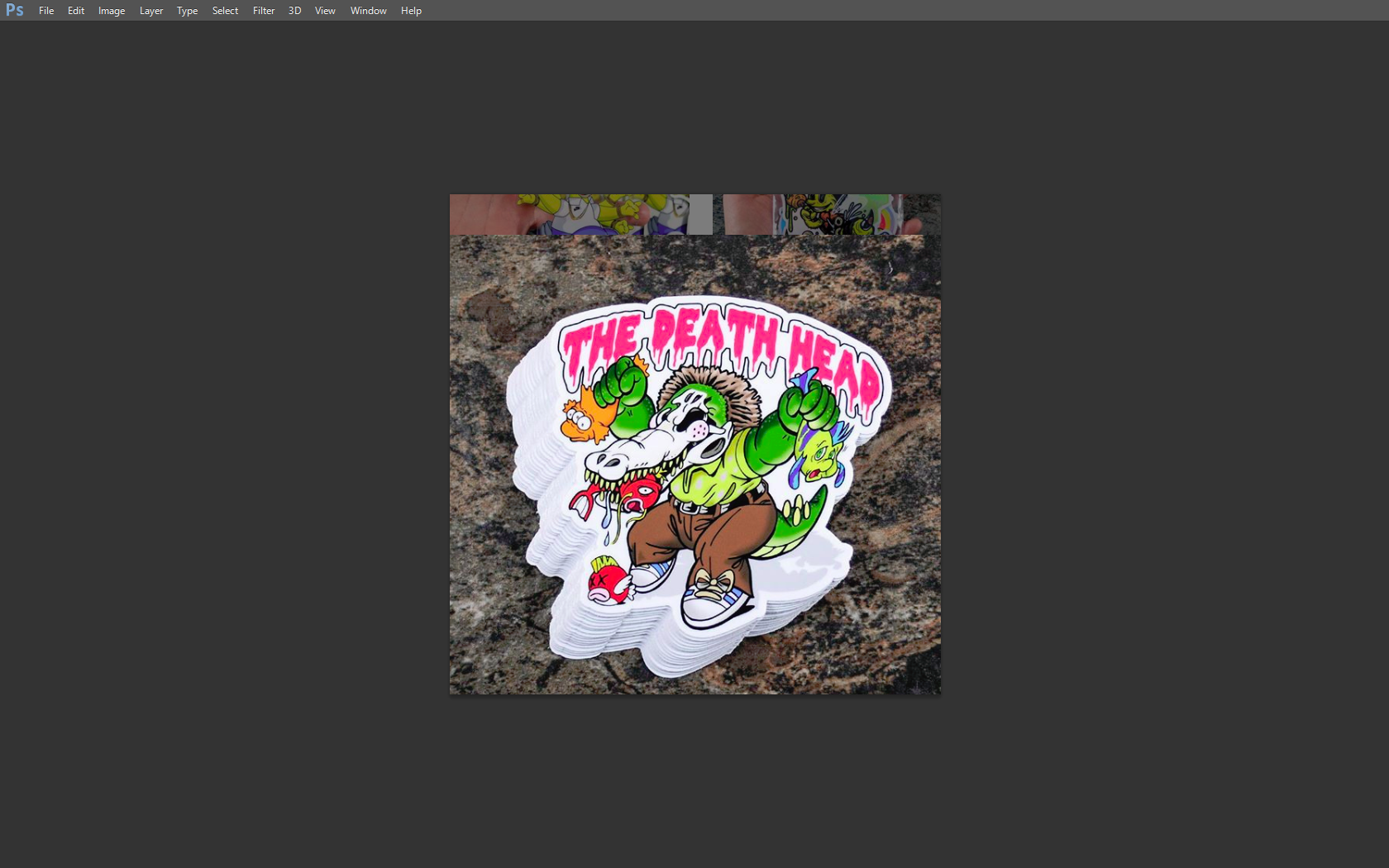

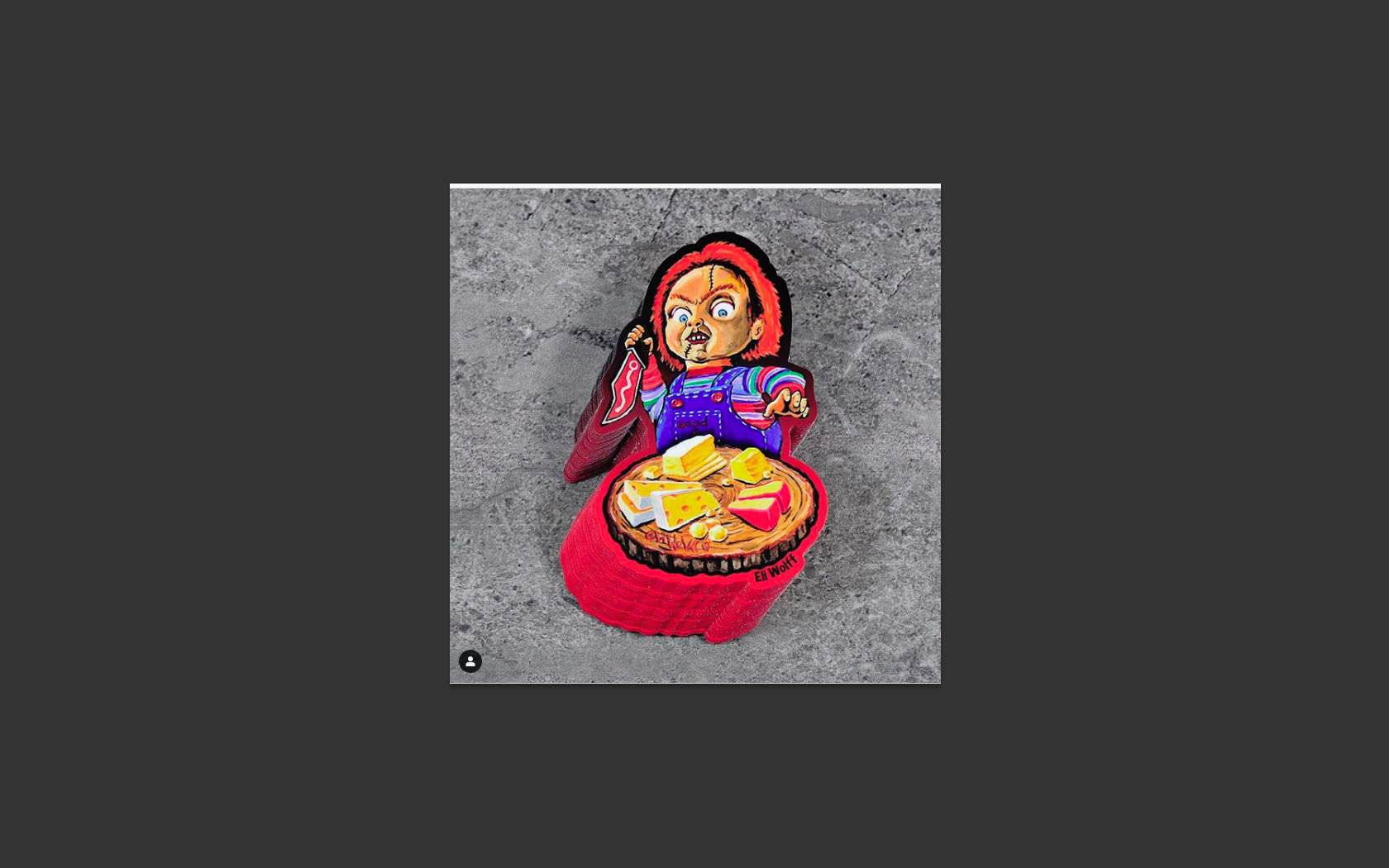

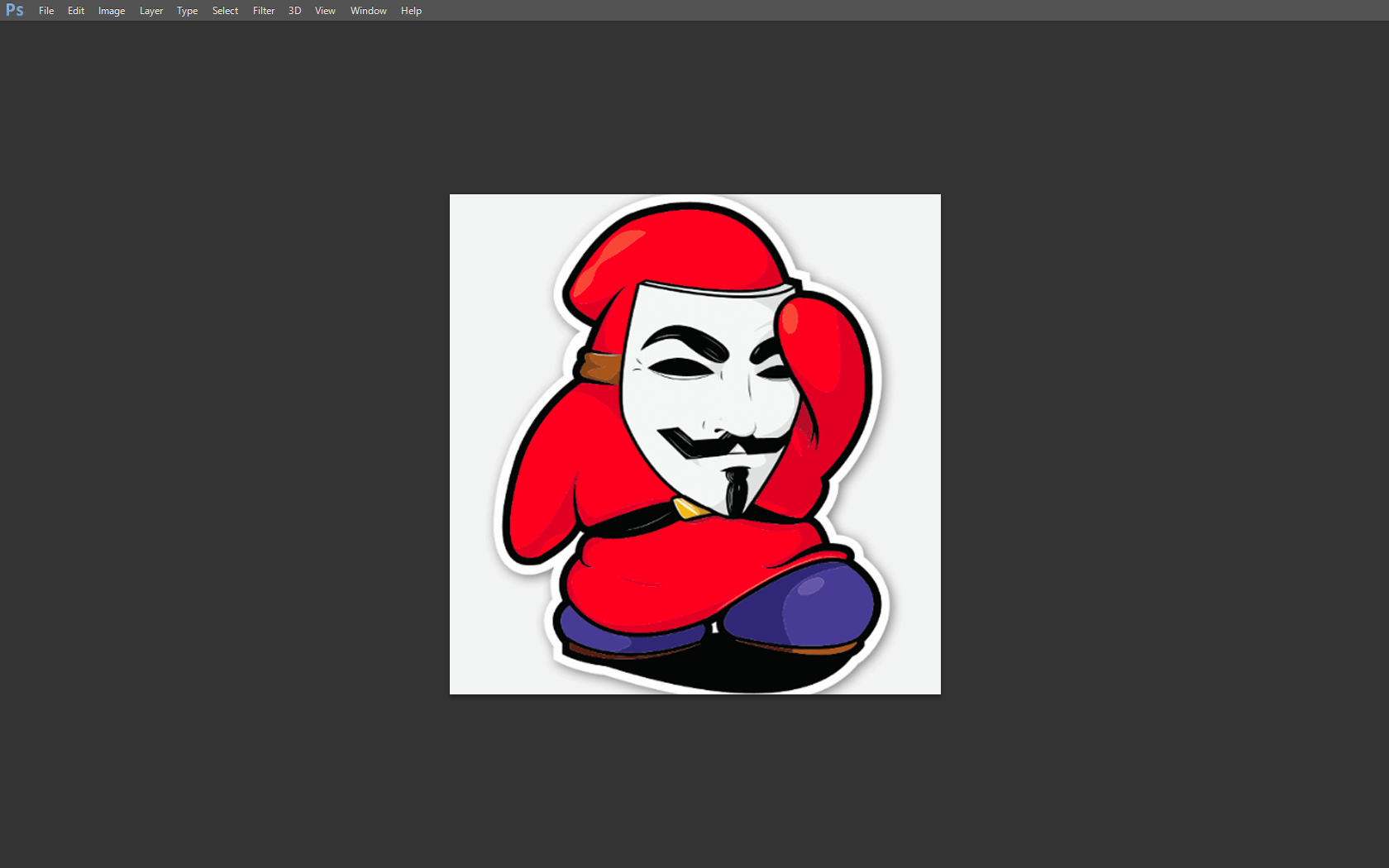

Here are some examples from companies...

What material are they using? Maybe something that doesn't have curl. The media I have tends to curl on the edges after a while.

I have an HP Latex 360 and a Canon iPF8400s.

For cutting, I have a Graphtec FC8600

Also, wouldn't I wear out my blade really quick using a Graphtec?

Here are some examples from companies...