n20capri

New Member

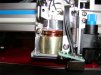

Graphtec model CE3000-60 MK2.

So all of a sudden it won't cut...it goes through the motions but the blade doesn't go down far enough...even when I switch to the pen tool it doesn't go down far enough...even with the force all the way up it won't even touch the paper/vinyl...

So I too off the dust cover thingy and noticed the copper coil didn't look right...looks unwound to me...can someone take a peek at theirs to compare...

If it's not this does anyone have any thoughts? Is there an adjustment that could cause the blade to not be going down far enough?

Any help is appreciated,

Thanks,

Mike

So all of a sudden it won't cut...it goes through the motions but the blade doesn't go down far enough...even when I switch to the pen tool it doesn't go down far enough...even with the force all the way up it won't even touch the paper/vinyl...

So I too off the dust cover thingy and noticed the copper coil didn't look right...looks unwound to me...can someone take a peek at theirs to compare...

If it's not this does anyone have any thoughts? Is there an adjustment that could cause the blade to not be going down far enough?

Any help is appreciated,

Thanks,

Mike

Attachments

Last edited by a moderator:

:

: