400 lb Gorilla

New Member

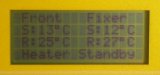

Could sure use a little help. I just replaced the black print head on my Falcon Outdoor JR. I prints perfectly except it is not aligned with the color print head any longer. I ran a "Head Alignment" procedure but apparently that only aligns the Left/Right print head movement, not the media feed direction. The test strip below shows a gap between where the black ends and the color begins. Anybody know how to get them back in sync?

Thanks!!

Thanks!!