AceLaser

New Member

Hello CNC Folks!

I just recovered from major repairs to our laser cutter (Air Filtration unit exploded, blown capacitors, water leaks everywhere inside and out!) just to have my 8' table start throwing an error code at me. Maybe y'all can help.

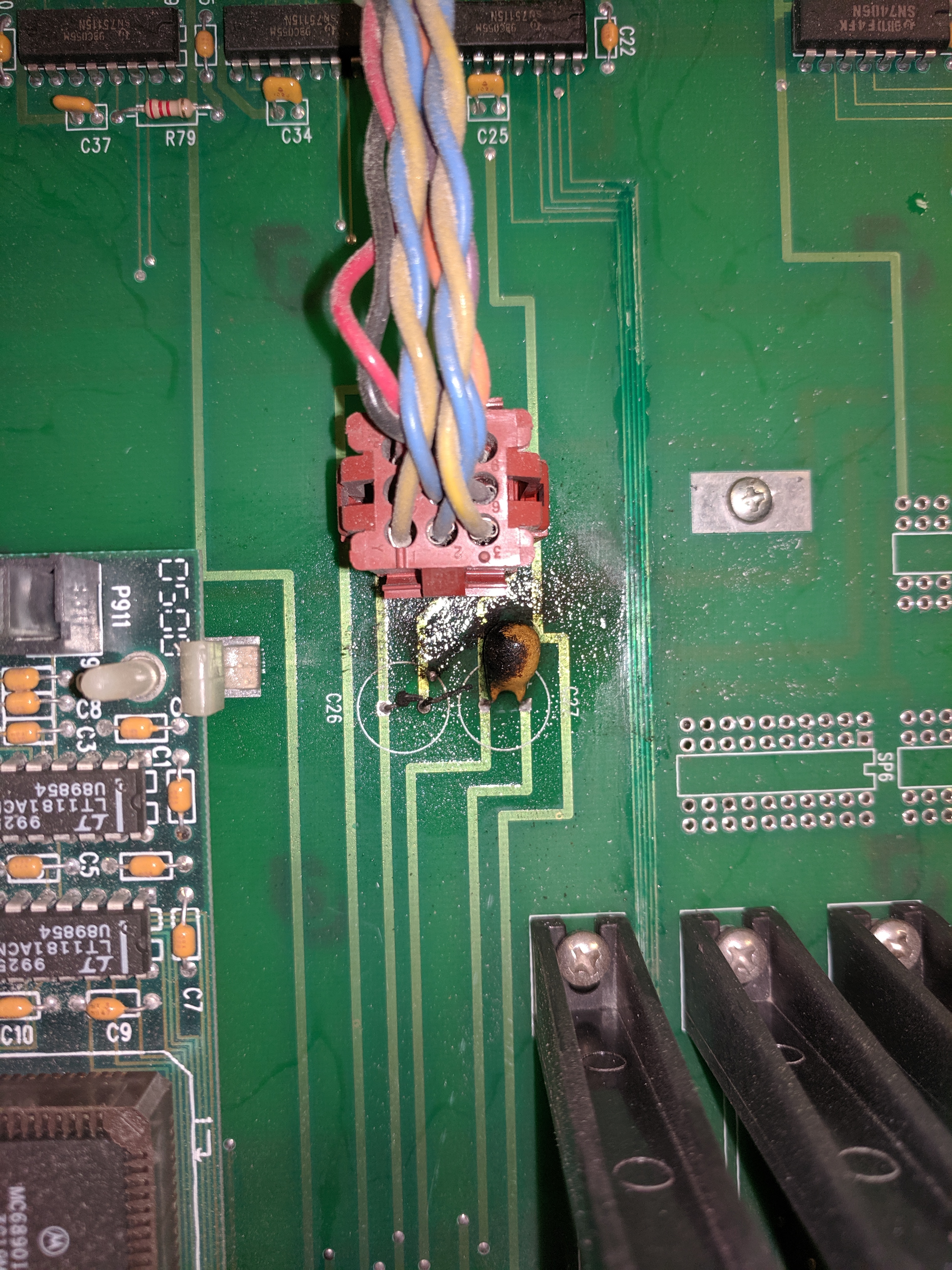

"UART OVERRUN" will pop up on the controller display and the spindle will stop in place - bit still under power. This code is basically telling me that the drip feed is still too much for the machine to read at a time. Called Gerber and was told that I am running a 1 meg board (Based off of a firmware reading) and need to be running a 4 meg to handle the data we are sending (Prismatic and Complex path objects). Popped the lid to get a couple of numbers and we see this.

Obvious, this is a problem - but I don't know if this is my root problem. Do any of you know anything about these boards? Or have access to any documentation on the board itself that I could read up on?

Any help here will be appreciated.

I just recovered from major repairs to our laser cutter (Air Filtration unit exploded, blown capacitors, water leaks everywhere inside and out!) just to have my 8' table start throwing an error code at me. Maybe y'all can help.

"UART OVERRUN" will pop up on the controller display and the spindle will stop in place - bit still under power. This code is basically telling me that the drip feed is still too much for the machine to read at a time. Called Gerber and was told that I am running a 1 meg board (Based off of a firmware reading) and need to be running a 4 meg to handle the data we are sending (Prismatic and Complex path objects). Popped the lid to get a couple of numbers and we see this.

Obvious, this is a problem - but I don't know if this is my root problem. Do any of you know anything about these boards? Or have access to any documentation on the board itself that I could read up on?

Any help here will be appreciated.