Hi

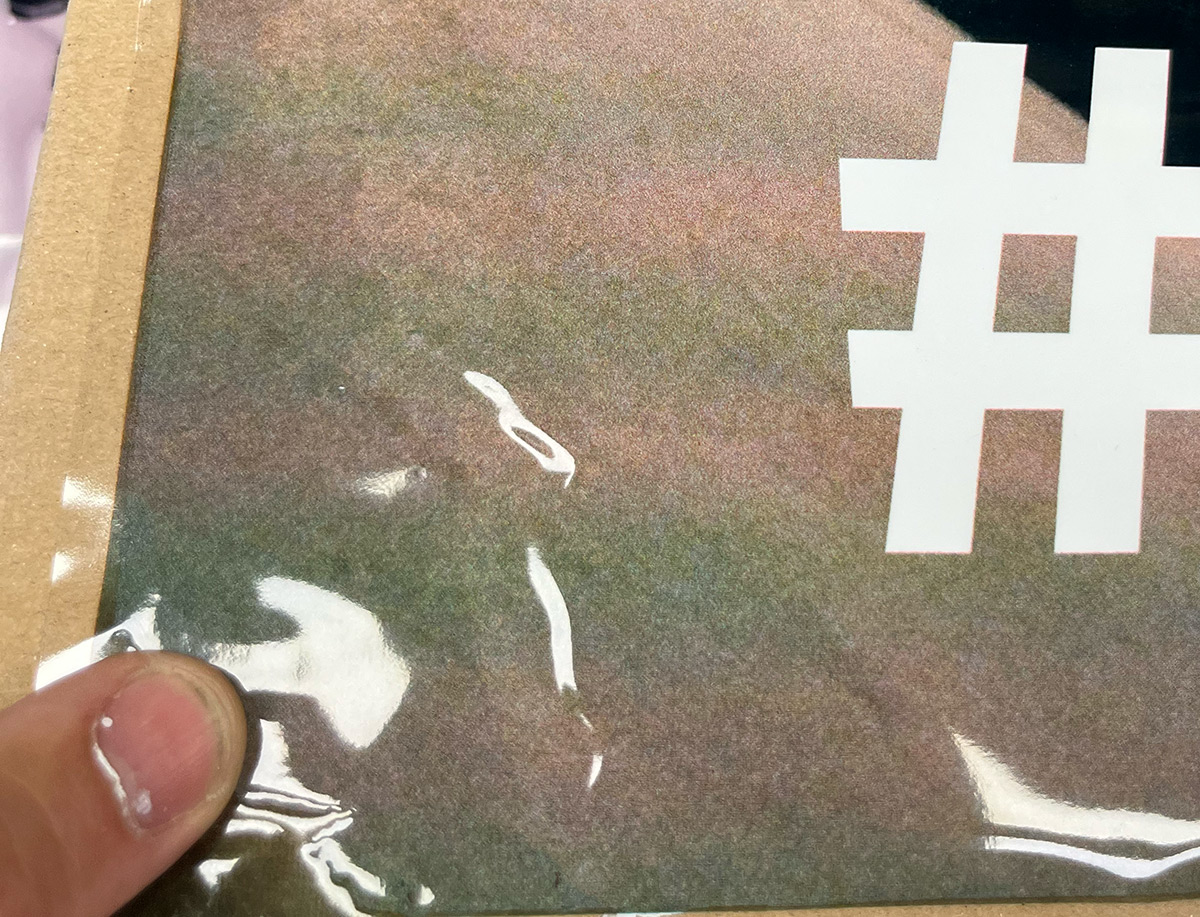

I need help on this issue. I think its not a classic banding error, not sure how to call it.

On gray tones, i get colored waves between blue and red in a 6cm interval.

Well, a picture will say more than 1000 words:

I have tried printing the designs horizontal and vertical, so its not in the fade / gradient of the colors.its always horizontal on the print.

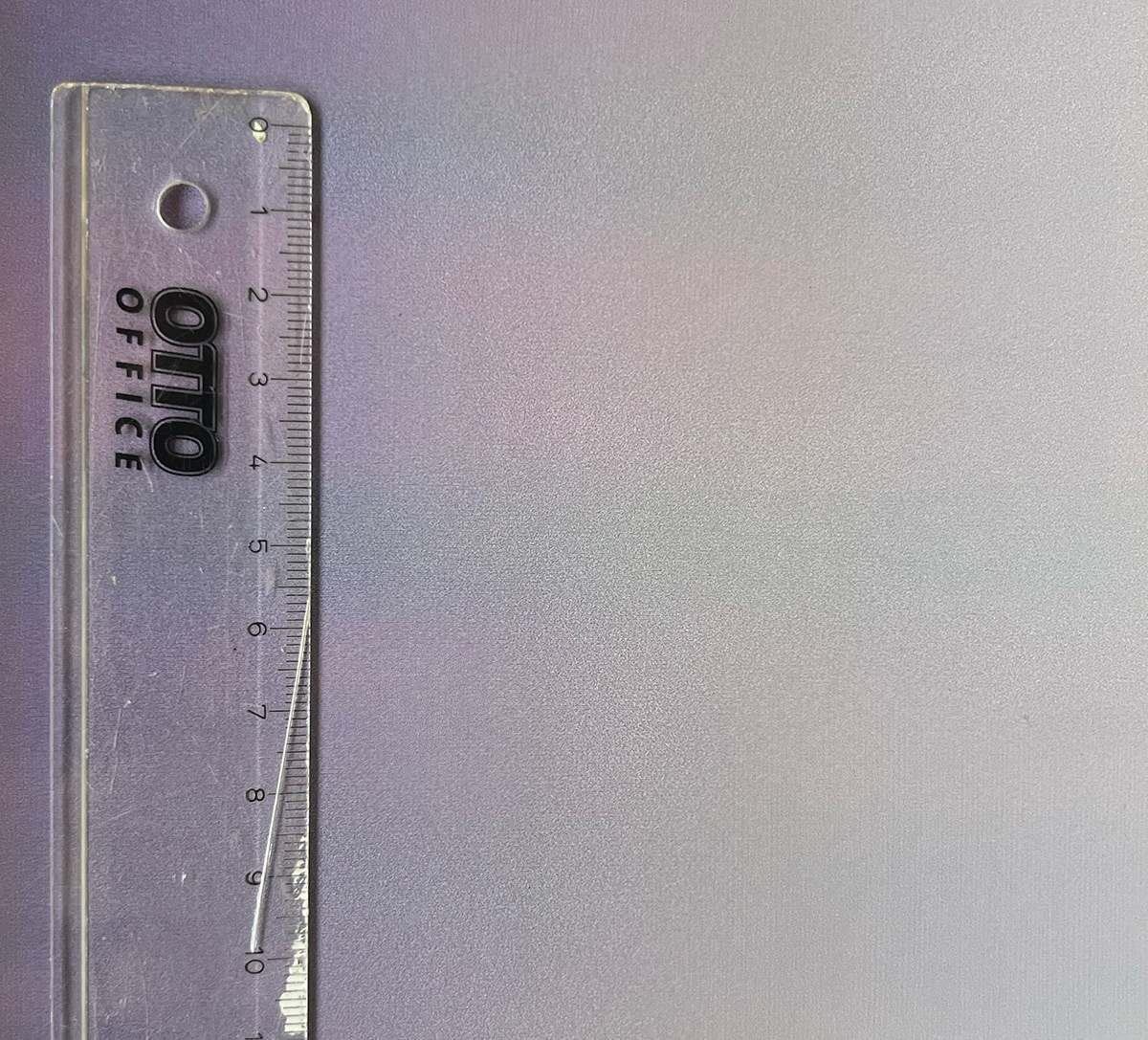

I need help on this issue. I think its not a classic banding error, not sure how to call it.

On gray tones, i get colored waves between blue and red in a 6cm interval.

Well, a picture will say more than 1000 words:

I have tried printing the designs horizontal and vertical, so its not in the fade / gradient of the colors.its always horizontal on the print.