SellersSign&Design

New Member

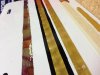

I have been working on gold leaf gilding. Everything seems to go alright until I get to the turning part. When I turn the leaf, it almost seems like it is gouging it. Then it really sticks out when the sealer is applied. I am using a cut up Crown Royal bag stuffed with cotton to do the turning (this was reccomended on the internet), and waiting 5-10 minutes after the leaf is applied. What am I doing wrong here???

Before the sealer was applied:

After sealer:

Sealer only on top half:

Before the sealer was applied:

After sealer:

Sealer only on top half:

What Round Man says...That's it in a nutshell!

What Round Man says...That's it in a nutshell!