Jake - Advantage Signs

New Member

Good afternoon Signs101 - long time, no see!

Since the shop is...a bit slow right now, I've been working on SOPs for production and finishing and I've come across one of those subjects that is apparently a controversy here in our shop - where to place grommets in relationship to the webbing in reinforced stitched hem.

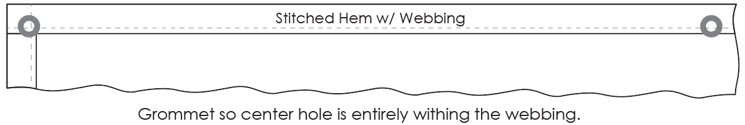

We use a 1" nylon webbing, and the person who does our stitching uses just a single line of stitching about 1/4" from the inside edge of the hem. The standard I train people on is to weight the grommet slightly towards the middle of the banner, so there is more webbing outside the grommet than inside, but the grommet is still fully within the webbing. Here's my SOP diagram:

Speaking with a couple of the production staff made me realize that they either forgot how they had been trained or that maybe someone that wasn't me trained them, and they will put the grommet centered in the webbing.

Do you have a standard? Where would place the grommet in 1" webbing?

(On a side note: the whole reason I even started talking with anyone about it was that I realized that I usually put the grommet in the MIDDLE of a taped hem - a hem made with 1" double sided banner tape. No idea why I have two personal standards, but I guess this is why it's good to revisit this stuff occasionally!)

Since the shop is...a bit slow right now, I've been working on SOPs for production and finishing and I've come across one of those subjects that is apparently a controversy here in our shop - where to place grommets in relationship to the webbing in reinforced stitched hem.

We use a 1" nylon webbing, and the person who does our stitching uses just a single line of stitching about 1/4" from the inside edge of the hem. The standard I train people on is to weight the grommet slightly towards the middle of the banner, so there is more webbing outside the grommet than inside, but the grommet is still fully within the webbing. Here's my SOP diagram:

Speaking with a couple of the production staff made me realize that they either forgot how they had been trained or that maybe someone that wasn't me trained them, and they will put the grommet centered in the webbing.

Do you have a standard? Where would place the grommet in 1" webbing?

(On a side note: the whole reason I even started talking with anyone about it was that I realized that I usually put the grommet in the MIDDLE of a taped hem - a hem made with 1" double sided banner tape. No idea why I have two personal standards, but I guess this is why it's good to revisit this stuff occasionally!)