Billings Sign Pro

Sign Company

Hey guys!

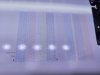

I have been having issues with one of the heads on our Roland TrueVis VGII-640. I was hoping one of you guys might have an idea as to how I can fix it. Is it a possible damper situation? It happens on our head that has the yellow and the black. Sometimes I have to do multiple cleans before I can get the issue to go away, but it always comes back. The pictures I have are dated for an older date but it is still happening today. There is an image where the lt. magenta and lt. cyan was having issues but that has been taken care of.

I have been having issues with one of the heads on our Roland TrueVis VGII-640. I was hoping one of you guys might have an idea as to how I can fix it. Is it a possible damper situation? It happens on our head that has the yellow and the black. Sometimes I have to do multiple cleans before I can get the issue to go away, but it always comes back. The pictures I have are dated for an older date but it is still happening today. There is an image where the lt. magenta and lt. cyan was having issues but that has been taken care of.