I have the Mimaki CJV150-130, I print laminate and cut. Usually I have no issues. Lately every contour cut I do it's pulling and ripping my stickers! I use illustrator make a cut line save it as an eps and open it in Rasterlink. Has worked for months with no issues. Its cutting in the right spots and the right design pattern but its shredding the stickers and paper backing. It makes them unusable. I have tried changing the speed, pressure and blade (45°). Nothing is helping. What am I doing wrong? Any suggestions??

-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question Help! Contour Cut Issues

- Thread starter Hart08

- Start date

OPENSignsInc.

New Member

My first thought if it's ripping through I'd check the blade tip to see if its broken.

The blade tip should just be barely sticking out of the holder (helps if you have a loupe to see/adjust the depth).

What vinyl/laminate & pressure are you running?

When was the last time you replaced the Kevlar strip?

Are you sending cut pressure with the print/cut file or using the profile on the machine?

The blade tip should just be barely sticking out of the holder (helps if you have a loupe to see/adjust the depth).

What vinyl/laminate & pressure are you running?

When was the last time you replaced the Kevlar strip?

Are you sending cut pressure with the print/cut file or using the profile on the machine?

White Haus

Not a Newbie

Not familiar with Mimakis at all - but have you checked the blade holder?

Did you suddenly start getting these results or did it gradually get worse?

Does it happen with all material combinations or just a specific one?

Did you suddenly start getting these results or did it gradually get worse?

Does it happen with all material combinations or just a specific one?

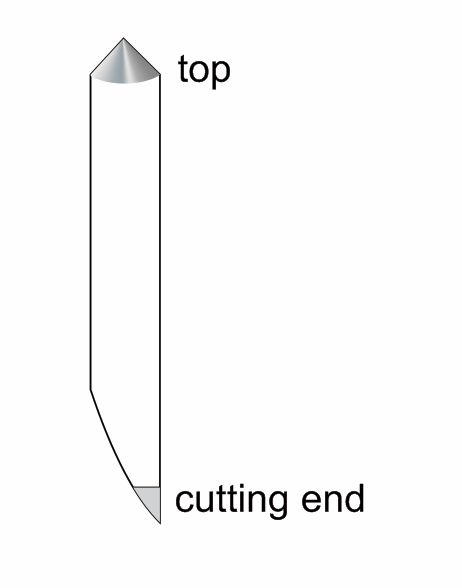

IMO you should use a 60º blade, but if 45º has been working for you then it’s obviously another problem. And this will sound CRAZY buuuuut.... when I started working at my present job, some idiot had loaded, AND WAS USING, the blade upside-down. It was cutting with the pivot end, making ragged edges. They didn’t notice because most everything we cut is very large.

So if you have employees, is it possible someone loaded a new blade upside-down. From experience I know that the pivot end WILL cut.

I can’t make this stuff up!

So if you have employees, is it possible someone loaded a new blade upside-down. From experience I know that the pivot end WILL cut.

I can’t make this stuff up!

My first thought if it's ripping through I'd check the blade tip to see if its broken.

The blade tip should just be barely sticking out of the holder (helps if you have a loupe to see/adjust the depth).

What vinyl/laminate & pressure are you running?

When was the last time you replaced the Kevlar strip?

Are you sending cut pressure with the print/cut file or using the profile on the machine?

The blade tip is fine, I replaced the blade hoping that was the problem but it still persists. Machine is only a couple months old so nothing should need to be replaced yet. I was using the profile on the machine for cut pressure. Tried multiple different pressures and speeds to see if it would change but no matter how slow or fast or deep it cuts it's still pulling it apart.

Not familiar with Mimakis at all - but have you checked the blade holder?

Did you suddenly start getting these results or did it gradually get worse?

Does it happen with all material combinations or just a specific one?

The blade holder is fine. Also replaced the blade. They just suddenly happen but only on contour cuts.

All material. Currently running orajet and orafol laminate.

IMO you should use a 60º blade, but if 45º has been working for you then it’s obviously another problem. And this will sound CRAZY buuuuut.... when I started working at my present job, some idiot had loaded, AND WAS USING, the blade upside-down. It was cutting with the pivot end, making ragged edges. They didn’t notice because most everything we cut is very large.

So if you have employees, is it possible someone loaded a new blade upside-down. From experience I know that the pivot end WILL cut.

I can’t make this stuff up!

Ha! That is crazy. No I work alone, the blade is not upside down. Lol. I was wondering if i should try 60° it came with a 45 and the tech who set it up said it would be great for contour cuts but he also said a lot of things that did not end up being true. Thanks for the opinion I'll check it out.

iPrintStuff

Prints stuff

Sounds like the blade is too far out. You need to just be able to see the end of the tip. For laminated vinyl I usually have the pressure at 200 if that helps.

equippaint

Active Member

Set the blade out about the thickness of a credit card. 200 sounds like a lot of pressure, were 95-135 on laminated vinyl depending on the material, 40 on 651 cal vinyl and I think thats a bit high. The more downforce you have, the more wear youre gonna have.

iPrintStuff

Prints stuff

Maybe I’ve just got the blade upside down

Alan Menhennet

New Member

Sounds like your blade might be too far out. Lift it up and play around with the pressue

Yes I did. We think we got it now. New blade in farther I'm cutting on 95 and it's working well. Didn't cut through enough on the last row so I might go up one more. Should be good from there. Thank you allSounds like your blade might be too far out. Lift it up and play around with the pressue

myront

Dammit, make it faster!!

Another method would be to make two cuts. First cut normal then an outer offset contour cut about an eighth of an inch to do the punch cut or "Half Cut" as they like to call it.

Also note that the blades you buy come with specs to set your offset and speed. And for giggles...

Also note that the blades you buy come with specs to set your offset and speed. And for giggles...