Hi guys, I'm new to the forum and I'd love your help in finding a better printer solution for the company I work for. Any ideas are greatly appreciated. With all the printing options out there, I'm hoping you can help me narrow down my options.

My work prints automotive gauge faces (speedometers, tachometers, etc). We offer a variety of colors on the faces including our most important colors: opaque black and opaque white. We must be able to print gauge faces that block out bright LEDs positioned directly behind the gauge face. Also, the gauge face is then laminated for greater rigidity and laser-cut into shape.

Currently we use the Gerber Edge printer which gives us the ability to achieve those opaque colors, however the Gerber Edge software is overly-complicated, the product performance is inconsistent, and it can only print vector art.

In a nutshell, I'm looking for a printer with these capabilities (in order from most critical to least):

• Can print both transparent colors and, most importantly, opaque black and opaque white (where bright LEDs won't shine through opaque parts)

• Can print tiny details in high resolution, both images and vector art

• Can print large quantities quickly

• Can print on rigid media to eliminate lamination process, if possible. (Perhaps we print gauge face backwards so there is no need for the additional lamination?)

• Can also cut to eliminate laser-cut process, if possible

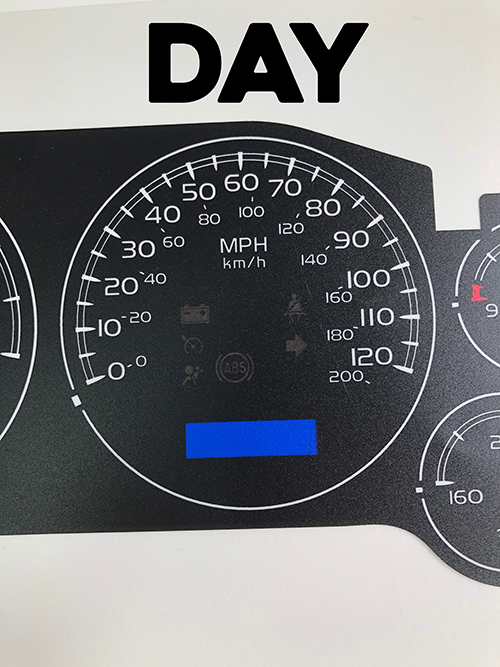

This printer I'm describing would be a dream! Below is an example of a gauge face that has both opaque and transparent colors. Thanks everyone.

My work prints automotive gauge faces (speedometers, tachometers, etc). We offer a variety of colors on the faces including our most important colors: opaque black and opaque white. We must be able to print gauge faces that block out bright LEDs positioned directly behind the gauge face. Also, the gauge face is then laminated for greater rigidity and laser-cut into shape.

Currently we use the Gerber Edge printer which gives us the ability to achieve those opaque colors, however the Gerber Edge software is overly-complicated, the product performance is inconsistent, and it can only print vector art.

In a nutshell, I'm looking for a printer with these capabilities (in order from most critical to least):

• Can print both transparent colors and, most importantly, opaque black and opaque white (where bright LEDs won't shine through opaque parts)

• Can print tiny details in high resolution, both images and vector art

• Can print large quantities quickly

• Can print on rigid media to eliminate lamination process, if possible. (Perhaps we print gauge face backwards so there is no need for the additional lamination?)

• Can also cut to eliminate laser-cut process, if possible

This printer I'm describing would be a dream! Below is an example of a gauge face that has both opaque and transparent colors. Thanks everyone.

Last edited: