Don't get too frustrated with some of our contributors. In many cases, they have spent tens of thousands of dollars on equipment and hundreds of hours to learn how to get the desired results.

To answer your question correctly, we would need a lot more information regarding your market and the scale of your output.

If you are a small (under $1 million year) general

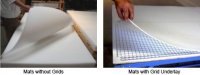

sign shop serving local community needs, all you probably need is a 4' x 8' 3/4" plywood table with a sheet of replaceable PVC on the top (I actually use 1/4" plate glass so I can cut on it too). The self-sealing mats are nice at first, but in my circumstances (low volume), just using an X-acto knife and a heavy ruler to cut and trim, they tend to get sliced up pretty fast. I use these tables for weeding, trimming, and cutting.

Consider your table height. In most cases you will want your work surface higher than a standard table top.

I drew a 1" grid on my MDO (under the glass) to help line things up when cutting. I also use the wet method and a felt squeegee (or at least a sleeve of some sort) to apply vinyl graphics onto substrates. Call me a coward, but I have been doing this since the beginning of time and have never had any problems.

For rigid substrates, I just set them on sawhorses and 2x4s.

If you are doing more production, you will want to look into a flatbed and direct printing.