-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Suggestions I have many 220 ink cartridges which still have ink in them

- Thread starter Jim Hill

- Start date

balstestrat

Problem Solver

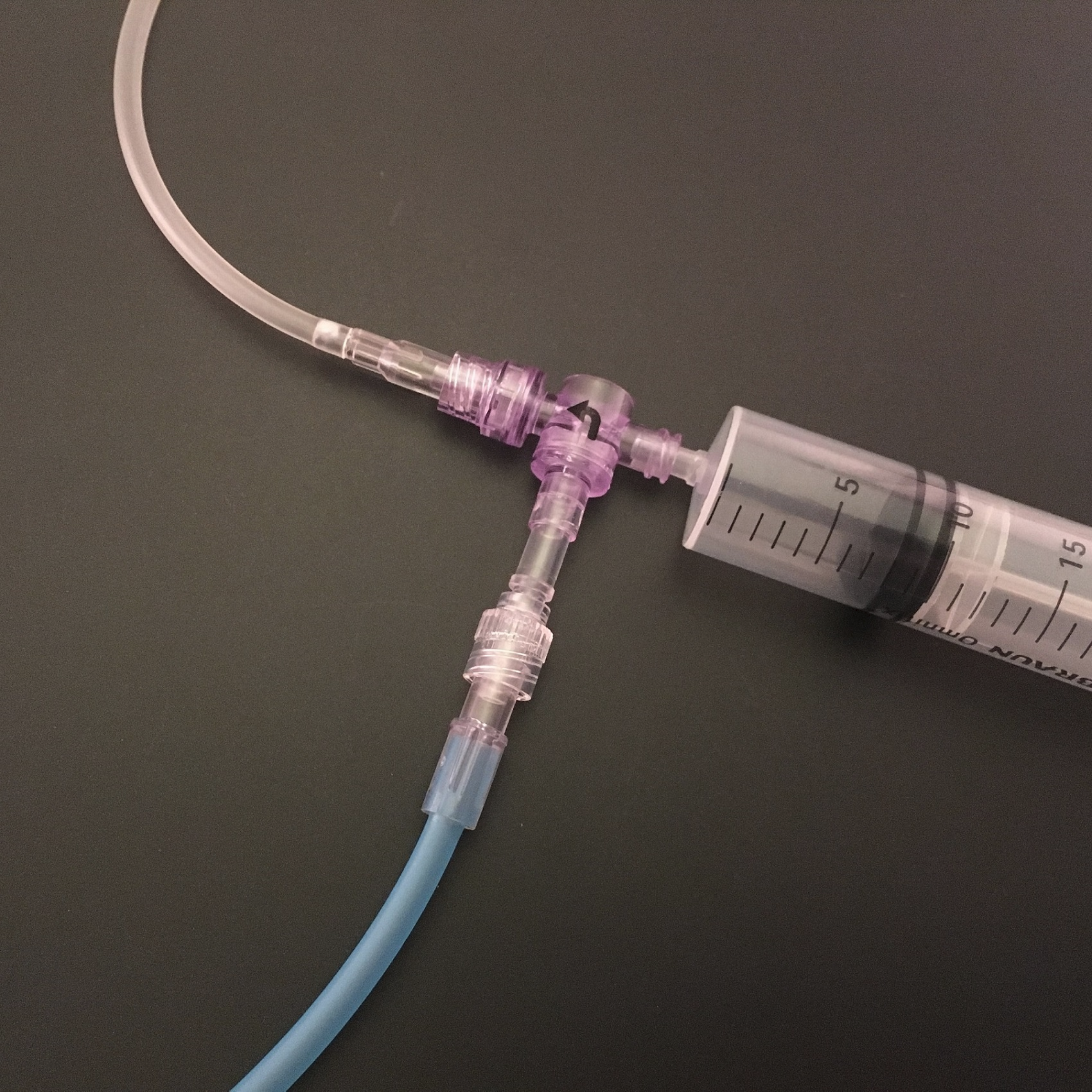

HP always has some really good ones with the spare parts. Blunt tip needles that won't puncture anything. Even a T-valve on a tube that you can change the direction of flow so you can basically pump ink between two cartridges.

Last edited:

Jim Hill

New Member

I have a few questions.HP always has some really good ones with the spare parts. Blunt tip needles that won't puncture anything. Even a T-valve on a tube that you can change the direction of flow so you can basically pump ink between two cartridges.

View attachment 157797

Where do I purchase this set-up and the approximate cost. You insert the needle into the end of a 220 ink cartridge that has ink left in it and once you draw the ink into the needle your then remove it and insert it into the correct color cartridge and reverse the value on the end of it. Is that correct? Thanks Jim

balstestrat

Problem Solver

No idea where you would purchase them but that's how I would do it if kept as simple as possible. Maybe your local pharmacy?

Then if there were A lot of stuff to transfer, I would probably add that T-valve or check valve.

Then if there were A lot of stuff to transfer, I would probably add that T-valve or check valve.

Solventinkjet

DIY Printer Fixing Guide

I'd suggest just getting some chips to put on the cartridge to finish them up. Cartridges are filled with ink and then all the air is sucked out. If you introduce air into the cartridge, it can cause pressure issue which usually ends up in ink just falling out of the head.

Jim Hill

New Member

Question when you say get some chips to put on the cartridge, what do you mean?I'd suggest just getting some chips to put on the cartridge to finish them up. Cartridges are filled with ink and then all the air is sucked out. If you introduce air into the cartridge, it can cause pressure issue which usually ends up in ink just falling out of the head.

I have installed shims under one end of the cartridge to raise the angle slightly, but there is still a good deal of ink in each cartridge, and I have many of them.

It seems so wasteful just to keep getting rid of cartridges with ink left in them.

Jim

Solventinkjet

DIY Printer Fixing Guide

Question when you say get some chips to put on the cartridge, what do you mean?

I have installed shims under one end of the cartridge to raise the angle slightly, but there is still a good deal of ink in each cartridge, and I have many of them.

It seems so wasteful just to keep getting rid of cartridges with ink left in them.

Jim

The way the system works is each cartridge has a chip that identifies the color but also keeps track of the ink level by subtracting the estimated ink usage as the machine is used. Once that hits 0, the chip reads as empty even if it estimated incorrectly and there is still ink present. Usually if a chip reads 0 before it's actually empty, it's a sign of a bad maintenance station or the next issue below.

There is another sensor in the cartridge area that detects if the cartridge is physically empty as well. It's a plastic flag that pops out of the cartridge when it's empty. When that trips, the cartridge should be as empty as it can be but sometimes it gets hit early and then sets the chip to 0 automatically even if ink is still present. Once a cartridge hits 0, the chip is done for good and will always read 0.

So in your case you might be in one of those situations and if that's the case, you can just get a new chip that is set to 100%, pop it on the cartridge and finish it off. Once the flag trips the sensor, it will set the chip to 0 again.

There's always a little ink left in the cartridge but it should be negligible. If you can feel ink still moving around in there on a regular basis, it could mean your maintenance station isn't pulling enough ink during cleanings. Essentially, that's the ink it would have pulled if it was working properly.

Jim Hill

New Member

Thanks for explaining that to me, as I did not know how that worked.The way the system works is each cartridge has a chip that identifies the color but also keeps track of the ink level by subtracting the estimated ink usage as the machine is used. Once that hits 0, the chip reads as empty even if it estimated incorrectly and there is still ink present. Usually if a chip reads 0 before it's actually empty, it's a sign of a bad maintenance station or the next issue below.

There is another sensor in the cartridge area that detects if the cartridge is physically empty as well. It's a plastic flag that pops out of the cartridge when it's empty. When that trips, the cartridge should be as empty as it can be but sometimes it gets hit early and then sets the chip to 0 automatically even if ink is still present. Once a cartridge hits 0, the chip is done for good and will always read 0.

So in your case you might be in one of those situations and if that's the case, you can just get a new chip that is set to 100%, pop it on the cartridge and finish it off. Once the flag trips the sensor, it will set the chip to 0 again.

There's always a little ink left in the cartridge but it should be negligible. If you can feel ink still moving around in there on a regular basis, it could mean your maintenance station isn't pulling enough ink during cleanings. Essentially, that's the ink it would have pulled if it was working properly.

Each cartridge I have has a good deal of ink left inside it. I will keep working on this problem because It's crazy to just keep wasting ink!

Jim

Solventinkjet

DIY Printer Fixing Guide

Thanks for explaining that to me, as I did not know how that worked.

Each cartridge I have has a good deal of ink left inside it. I will keep working on this problem because It's crazy to just keep wasting ink!

Jim

I agree. I much prefer the bottle with sub tank and float sensor much better over cartridge. It allows you to use all the ink!

What i did is open up the nearly empty cartridge, roll up the pouch like a toothpaste tube, insert the needle holding the pouch upside down - the rubber plug facing downwards, get the ink out and hold the new cartridge upside down again when inserting the needle and make sure you don't insert it too deep. You can inject 150-200ml easily as the pouches are not filled up too much even when brand new.

Your syringe needs to be 200ml (200cc) as the leftower is usually between 100-150ml

If you happen to puncture the bag hot glue will seal it (don't ask me how do I know), don't use vinyl as ink will dissolve it over time.

Your syringe needs to be 200ml (200cc) as the leftower is usually between 100-150ml

If you happen to puncture the bag hot glue will seal it (don't ask me how do I know), don't use vinyl as ink will dissolve it over time.

Jim Hill

New Member

ewded:

Thank you for responding.

I like your idea and may give it a try.

It does sound labor-intensive and since I have maybe 12 to 24 ink cartridges sitting on shelves might not be worth the effort.

Your statement was the following,

"If you happen to puncture the bag hot glue will seal it (don't ask me how do I know), don't use vinyl as ink will dissolve it over time" What were you referring to when you said don't use vinyl as ink will dissolve it over time?

I appreciate you sharing your knowledge on this subject. Jim

Thank you for responding.

I like your idea and may give it a try.

It does sound labor-intensive and since I have maybe 12 to 24 ink cartridges sitting on shelves might not be worth the effort.

Your statement was the following,

"If you happen to puncture the bag hot glue will seal it (don't ask me how do I know), don't use vinyl as ink will dissolve it over time" What were you referring to when you said don't use vinyl as ink will dissolve it over time?

I appreciate you sharing your knowledge on this subject. Jim

Jim Hill

New Member

On a Roland Ink Cartridge, there is a small circuit board on the front of every cartridge, is that what control the ink flow and everything else?

There is only one small screw holding it in place.

If I replace this with the circuit board off a new cartridge, would it work? Kind of like using a chip resetter.

I have not tried it yet and was just wondering if anyone else has>

Jim

There is only one small screw holding it in place.

If I replace this with the circuit board off a new cartridge, would it work? Kind of like using a chip resetter.

I have not tried it yet and was just wondering if anyone else has>

Jim

Superior_Adam

New Member

Seems to me adding ink to another cartridge will only leave you with that much left over in the newer cartridge. The chips are accounting for a certain volume of ink. Once the machine thinks it has used that ink it reads zero. If it thinks there is 220mL worth of ink and you add 50mL you will still be left with 50mL. Putting a new chip on it seems like the more reliable solution other than resolving why you have so much ink left over.

The chip doesn't control ink flow, it stores the percentage left (printer tells it to the chip and can count down only), expiry date, color, and if cartridge is genuine, so if you have 9% left and put it on another cartridge it'll still show 9%.On a Roland Ink Cartridge, there is a small circuit board on the front of every cartridge, is that what control the ink flow and everything else?

There is only one small screw holding it in place.

If I replace this with the circuit board off a new cartridge, would it work? Kind of like using a chip resetter.

I have not tried it yet and was just wondering if anyone else has>

Jim

Yes it's time-consuming and messy if not done carefully, when i had more time than money (orders) I used to that, now that my time is more precious I don't mind throwing out 50ml of ink which is 10% waste on a 440ml cartridge ($8-$9)

don't use vinyl as ink will dissolve it over time ->> when trying to fix a puncture on an ink bag

balstestrat

Problem Solver

I think the opposite. You are making it sound way more difficult than it is. Just keep the air in the syringe and start transferring. You are probably done in 15 minutes.

Jim Hill

New Member

The chip doesn't control ink flow, it stores the percentage left (printer tells it to the chip and can count down only), expiry date, color, and if cartridge is genuine, so if you have 9% left and put it on another cartridge it'll still show 9%.

Yes it's time-consuming and messy if not done carefully, when i had more time than money (orders) I used to that, now that my time is more precious I don't mind throwing out 50ml of ink which is 10% waste on a 440ml cartridge ($8-$9)

don't use vinyl as ink will dissolve it over time ->> when trying to fix a puncture on an ink bag

So if I take the chip off a new ink cartridge and install it on an old cartridge, would it work?

I am also thinking for the first time about using after market cartridges and ink, but not sure which ink works the best in Roland printers.

My SP-300 is now considered a legacy printer, and Roland no longer supports or will sell me parts for it.

I have other sources for getting all the parts that I need to keep it running, and it works perfectly and is a great little printer.

Jim

Ink is not very expensive anyway, I wouldn't bother with 3rd part inks, on the long run you save how much? $10/ month? Just get some decent jobs and don't worry about the ink (obviously don't be the guy selling banners for $2.99 on ebay)

The SP-300 is still a decent little printer, the only limitation is the width it can print but other than that it's still better than a brand new TrueVis junk.

The SP-300 is still a decent little printer, the only limitation is the width it can print but other than that it's still better than a brand new TrueVis junk.