Gene@mpls

New Member

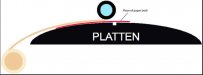

Has engineers who can build incredible machinery, but don't understand that when you try to load vinyl from a roll... the edge will tend to catch in any groove that is put in the platten, unless you could, maybe, undercut the downwind side a smidge?

Every Roland printer I have had has the same problem- as well as my Roland plotter (which I load from the front, so maybe both upwind and downwind could be relieved just a bit). That said, this stuff has made a very nice retirement for me. I have just always wondered about this. Gene

Every Roland printer I have had has the same problem- as well as my Roland plotter (which I load from the front, so maybe both upwind and downwind could be relieved just a bit). That said, this stuff has made a very nice retirement for me. I have just always wondered about this. Gene